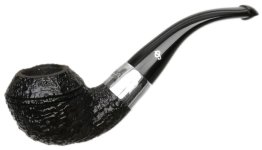

Since we are at it.. Stems. Please make them straight. I heard since Peterson is factory pipe, slight twist or bent is normal. Maybe. But Savinelli don't seems to have as much problem with their pipes and stems. As much as I love Peterson pipes, stems must be the weakest point. I have two beautiful stummels with some nasty stems. They were just cut wrong. Spoke in length with SP rep, very polite young lady. I didn't send them in for new stems. The inlay "P" can not be placed in newly cut stems. Does Ireland factory put those in? Better stem shaping/cutting will make Peterson a better pipes to own.

What's in play here is that the "stem half" of a pipe is more difficult to make than the "bowl half" as a categortical thing.

NOTE --- I'm

not referring to imaginative shaping and holding good lines... that's artisan territory and difficult to do well. I'm talking about factory pipes with fraized stummels.

Why are stems more difficult than bowls? Because the acceptable dimensional tolerance of a stem is measured in

thousandths of an inch, while a stummel is measured in

hundredths. Meaning a stem is a full order of magnitude more fussy and demanding to "get right".

Couple that with acrylic and vulcanite being physically tougher & more difficult to cut, shape, and polish than wood, and the first thing to be targeted by a manufacturer to hit price points is stem work.

On a related note, know that Peterson has never sacrificed stem

material quality to meet price points, but only looked at labor.

What am I referring to? The widely available snappy, crumbly, chippy acrylic that many Italian companies use. The stuff can be shaped (to a degree) with buffing wheels, and shines like glass with little effort, but it deteriorates rapidly. How fragile does it get? Buttons chip, bite zones crack, and tenons snap off easily. I have a pipe on its way to me as I type that was simply being held in one hand and fell apart while being polished by the other. And in the past I've been sent pipes whose bowls simply fell off spontaneously while smoking.

In short, a manufacturer saves 20 minutes (or whatever the actual number is)

one time, while the buyer gets to deal with the fragility for

life.

Not cool, sez me. "Cost Account Driven Design" has no place in the PipeWorld when

DURABILITY is compromised.

Why? Because what fuels the PipeWorld are

long-lasting items---meaning a hundred years and more---that are treasured for their history, personality, and individuality. The End. Full stop.

Anyway, back to the point: Peterson does not do that. They know that shape, finish & etc. can always be tuned and adjusted after purchase (if desired), but materials are forever.