Yeah your Altinay is like the brother of mine!View attachment 191906

My Altinay on the left here has the same style fitting as yours and my AGovem on the right has the screw in push-pull. Does the altinay have a more open airflow? Yes. Does it smoke better than the AGovem? No. They both smoke incredibly well I just pack the AGovem slightly lighter. Since I only have one pipes of each tenon-style my opinion is purely anecdotal as I don’t have a large enough sample size. Others would have to chime in. This is just my experience with my two pipes.

Didimauw's One Meer for One Year Redemption. 12/15/2022

- Thread starter didimauw

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Watch for Updates Twice a Week

Tinderbox, while diminished from its glory days, still has a web site.

This is the conventional wisdom I learned about meerschaum pipes nearly fifty years ago:

The Major Steps in Creating a Meerschaum Pipe

1. MINING - Meerschaum is mined in up to 450 feet of clay, sand, and gravel near Eskishehir, Turkey, and in Tanzania, Africa.

2. WASHING - The raw lumps of Meerschaum are washed to remove the dirt and gravel. assist you in selecting the Briar pipe that's just right for you.

3. GRADING - The meerschaum stones are graded into five categories with twelve qualities in each. Grading is based on size, density, color, and homogeneity.

4. SPLITTING - When the manufacturer receives a shipment of raw Meerschaum it must be split into smaller pieces for fashioning into pipes. A senior craftsman examines it very carefully, calculating precisely where the clumps should be split, much as in the cutting of fine gem stones. The many natural "fault lines" must be eliminated. As much as 80% of the raw material may be discarded at this stage.

5. CARVING - The Meerschaum blocks are soaked in water for 15 to 30 minutes to further soften the material to a cheese-like consistency before carving. Skilled craftsmen then fashion the Meerschaum into standard shape pipes or the magnificent sculptured pieces so highly prized by collectors.

6. HAND FITTING OF THE STEM - Before Polishing, a Meerschaum pipe is fitted with the stem or mouth-piece. In days gone by, stems were made of pure amber. Today, amber-colored Lucite is used almost exclusively. Pure amber is fine for collectors' pipes, but for the steady smoker, Lucite is much better because it is stronger, more resilient, and more comfortable in the mouth.

7. POLISHING - Only the finest abrasives can be used for polishing the soft Meerschaum. This step is long and tedious as too much pressure would mar the smooth finish.

8. WAXING - How well your Meerschaum will color is largely determined by the waxing. The pipes are dipped in molten bees-wax as many as 8 times to ensure proper coloring.

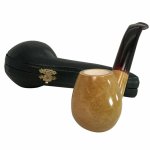

9. FINAL INSPECTION - A specialist carefully examines each finished pipe. The slightest flaw even at this late stage is just reason for the pipe's destruction. Finer quality Meerschaums are protected by a fitted case made for each individual pipe.

—

I’ve dug out my meers, and I appreciate them more than I did before I read this thread.

At 3 grams of tobacco a day, sometime close after Memorial Day (Decoration Day in Ozark American) I should have Jack colored a bit and need another pound of Creme Brulee.

So far this is a right pleasant New Year’s resolution to keep.

This is the conventional wisdom I learned about meerschaum pipes nearly fifty years ago:

The Major Steps in Creating a Meerschaum Pipe

1. MINING - Meerschaum is mined in up to 450 feet of clay, sand, and gravel near Eskishehir, Turkey, and in Tanzania, Africa.

2. WASHING - The raw lumps of Meerschaum are washed to remove the dirt and gravel. assist you in selecting the Briar pipe that's just right for you.

3. GRADING - The meerschaum stones are graded into five categories with twelve qualities in each. Grading is based on size, density, color, and homogeneity.

4. SPLITTING - When the manufacturer receives a shipment of raw Meerschaum it must be split into smaller pieces for fashioning into pipes. A senior craftsman examines it very carefully, calculating precisely where the clumps should be split, much as in the cutting of fine gem stones. The many natural "fault lines" must be eliminated. As much as 80% of the raw material may be discarded at this stage.

5. CARVING - The Meerschaum blocks are soaked in water for 15 to 30 minutes to further soften the material to a cheese-like consistency before carving. Skilled craftsmen then fashion the Meerschaum into standard shape pipes or the magnificent sculptured pieces so highly prized by collectors.

6. HAND FITTING OF THE STEM - Before Polishing, a Meerschaum pipe is fitted with the stem or mouth-piece. In days gone by, stems were made of pure amber. Today, amber-colored Lucite is used almost exclusively. Pure amber is fine for collectors' pipes, but for the steady smoker, Lucite is much better because it is stronger, more resilient, and more comfortable in the mouth.

7. POLISHING - Only the finest abrasives can be used for polishing the soft Meerschaum. This step is long and tedious as too much pressure would mar the smooth finish.

8. WAXING - How well your Meerschaum will color is largely determined by the waxing. The pipes are dipped in molten bees-wax as many as 8 times to ensure proper coloring.

9. FINAL INSPECTION - A specialist carefully examines each finished pipe. The slightest flaw even at this late stage is just reason for the pipe's destruction. Finer quality Meerschaums are protected by a fitted case made for each individual pipe.

—

I’ve dug out my meers, and I appreciate them more than I did before I read this thread.

At 3 grams of tobacco a day, sometime close after Memorial Day (Decoration Day in Ozark American) I should have Jack colored a bit and need another pound of Creme Brulee.

So far this is a right pleasant New Year’s resolution to keep.

Not saying anything negative about either, just commenting on how most meerschaum producers are going to the briar type. To my knowledge, Baki and Albayrak were two of the first to go to it.As someone who regularly smokes meerschaums with both tenon types (the briar style and the screwed in push-pull), I don’t understand the obsession with the briar-style tenons. Both tenons smoke equally well in my opinion and I’d imagine that since the screw in ones are more modular that they’ll stand up better to the test of time as they’re easily replaced. Aren’t the briar-style ones permanently affixed or am I mistaken?

I like how blackmeerschaum does theirs. Interesting concept.Not saying anything negative about either, just commenting on how most meerschaum producers are going to the briar type. To my knowledge, Baki and Albayrak were two of the first to go to it.

I'd be afraid of those. When the briar expands from heat and moisture, it may crack the meerschaum.I like how blackmeerschaum does theirs. Interesting concept.

This is pretty spectacular

VINTAGE AMAZING HAND CARVED S. Yanik MEERSCHAUM PIPE SKELETON SKULL &SCALY CLAWS | eBay

Find many great new & used options and get the best deals for VINTAGE AMAZING HAND CARVED S. Yanik MEERSCHAUM PIPE SKELETON SKULL &SCALY CLAWS at the best online prices at eBay! Free shipping for many products!

www.ebay.com

As much as I like his work, not many modern meerschaum carvers can do justice to a skull.This is pretty spectacular

VINTAGE AMAZING HAND CARVED S. Yanik MEERSCHAUM PIPE SKELETON SKULL &SCALY CLAWS | eBay

Find many great new & used options and get the best deals for VINTAGE AMAZING HAND CARVED S. Yanik MEERSCHAUM PIPE SKELETON SKULL &SCALY CLAWS at the best online prices at eBay! Free shipping for many products!www.ebay.com

I'm not certain of anything, but it doesn't appear to look like a pipe from the 1800's, and that just doesn't seem like Fikri. But what do I know, I'm still working on trying to get some good color on my own Baki.I'm still not entirely certain that the bottom wasn't precolored like those meerschaums of the 1800s.

Do you have a pic of it?I'm not certain of anything, but it doesn't appear to look like a pipe from the 1800's, and that just doesn't seem like Fikri. But what do I know, I'm still working on trying to get some good color on my own Baki.

It's very nice! Good looking lattice.View attachment 191991

View attachment 191992

I don't smoke from it as often as I should, but this thread has urged me to do a better job

No, it's one of his but it appears that the lower portion of it was colored like the old ones prior to smoking.it doesn't appear to look like a pipe from the 1800's,

Ok, but what is the saying... don't judge a book ... or don't judge a meer by it's color lol.No, it's one of his but it appears that the lower portion of it was colored like the old ones prior to smoking.

I mean, you probably know as much about these Meer carvers as anyone on this forum, so does that really sound like something he would do to his own pipe? Perhaps he was trying out the "old way" to see what would happen? It's a reasonable observation for sure.

Maybe I just don't want my unreasonable expectations of that Fikri Baki pipe to be tarnished lol.

Many of then use multiple different colored stained wax on their pipes so it wouldn't surprise me. One would think this pipe's color came from smoking but much of it was stained oxblood.

View attachment 192031

Yes, I've seen the oxblood stained pipes.

Myself, personally, it doesn't look like a tobacco stained pipe. I can usually spot the red oxblood pretty quick. What colored wax treatments do you think might have been used on the bottom of Fikri's pipe that they used in the 1800's? I haven't heard of any that gives that deep dark brown, almost black color, but once again, I don't know much about the subject, but I'm interested to learn more!

Several companies use stained wax, brown being amongst them.Yes, I've seen the oxblood stained pipes.

Myself, personally, it doesn't look like a tobacco stained pipe. I can usually spot the red oxblood pretty quick. What colored wax treatments do you think might have been used on the bottom of Fikri's pipe that they used in the 1800's? I haven't heard of any that gives that deep dark brown, almost black color, but once again, I don't know much about the subject, but I'm interested to learn more!

It wouldn't be a stretch to use it. Though I'm not saying he did, it wouldn't surprise me.

Last edited:

Several companies use stained wax, brown being amongst them.

View attachment 192041View attachment 192042

It wouldn't be a stretch to use it though I'm not saying he did, though it wouldn't surprise me.

Ya, I'm just not seeing it.

I'm sticking with this is the coolest "naturally" stained meer that exists on the planet.

The story goes that it was colored like that in six months, so I'm not buying it.View attachment 192045

Ya, I'm just not seeing it.

I'm sticking with this is the coolest "naturally" stained meer that exists on the planet.

Given the gaps on this pipe, it may not be as evenly dense as a "typical" Meerschaum—maybe it did colour naturally and the smoke and juices penetrated more easily through the porous sections that are dark?The story goes that it was colored like that in six months, so I'm not buying it.

Ya, I heard that too. I'm definitely not buying that. I'm inclined to believe that it is as you say.. a story, with no basis of fact. It simply sounded good, so off it goes into the digital media and people start quoting it as if they heard the man say it himself.The story goes that it was colored like that in six months, so I'm not buying it.

![IMG_0236[109].jpg IMG_0236[109].jpg](https://pipesmagazine.com/forums/data/attachments/191/191991-bb9f72784ccb3bef6c3f9a7c7fd6e574.jpg)