Vegas Baby

The show started out strong on the 14th floor hospitality suites hosted by the Vegas Pipe Show and Smoking Pipes as well as room hopping to carvers, estate sellers, and vendors to pre-game for the festivities. If you’re interested in what that looks like I’ll refer you to last years pipe show round up. I circled with Brian Levine to get the totals in comparison to last year:

This year’s show numbers: 108 Exhibitor tables, 445 attendees, 3,250 Raffle Tickets, 100ish dinners, 172 Rooms in the Hotel.

Last year, by comparison, 107 exhibitor tables, 425 attendees, 2,200 raffle tickets, 104 dinners, and 175 rooms on Friday and Saturday nights.

We were at capacity, basically, when it came to vendor tables and the dinner, so there is no physical room for growth at this point except for attendees. That said, we filled that smoking lounge to the brim.

New Carvers Spotlight

Garret Woo (Pipes by Woo)

How long have you been carving?

Garret: I’ve been carving since 2021, and I’m guessing your next question is probably how’d you get started carving?

James: Yes.

Garret: In 2021 I took a break from my full time job – that included machining and assembly work and I thought maybe it was time I made something that I would like and I started looking at youtube and Instagram and putting together my shop. I did struggle on the stems to start and there was a lot of failure at the beginning.

James: How many pipes have you made so far?

Garret: I number my pipes, so I just finished up 186.

James: What is your favorite shape you’ve been making?

Garret: I really dig Canadians and pipes with longer shanks and lovat Canadian blends. I like to play with different shapes of stems on the longer shanked pipes. The billiard would be my go-to shape but I want to learn more techniques on freehanded shapes. I like to put brass and copper adornments on my pipes with my machining background it helps.

James: What is the craziest thing you’ve seen at this show?

Garret: The first thing that comes to mind is the table over there with C-Pipes with the shapes and the size and petiteness and the intricate details they did.

You can check out what Garret is working on by going to his Instagram.

Stefan Cashwell

James: how long have you been carving?

Stefan: about 3 years.

James: What’s the craziest thing you’ve seen at the show?

Stefan: The Adam Davidson pipe with the clear shape and the bamboo—I don’t know if it’s 3D printed or what, but it’s amazing.

James: What’s your favorite shape to do?

Stefan: That’s a tough question. I think they’re all the same shape, but what’s fascinating is that Dublin, volcano, and blowfish are all the same depending on how you turn them. Playing with that, with all its variations, is a lot of fun. My favorite accent to use is also horn; it’s finicky, but it’s a great accent on pipes.

You can check out Stefan’s work on his Instagram.

Science: Meet Pipes

I chatted with Chris from the San Diego Pipe Club; he started off doing stem replacements for estate pipes but also improved the airflow.

James: How are you doing 3d printing? What is the thought process?

Chris: It’s a 3D-printed pipe with a briar insert. The design is a calabash meets a Peterson system meets a metal Falcon/Kirsten radiator style. It is a bottom draft smoking bowl like a radiator like those metal pipes. The inside chamber is a calabash. The stummel and accent rings in the stems are all 3d printed. The insert is briar, olive wood, or I have the potential to use meerschaum as well. This idea came about through the San Diego Pipe Club, wanting to see if we could 3D print a pipe and being curious about the technology; I have a printer and design ability, so here we are.

James: What’s the type of plastic you’re using?

Chris: It’s all PLA plastic, a renewable potato starch plastic that is food-safe. The stummels are printed with a plastic that has wood in it 40% wood fiber, bamboo, rosewood, ebony, redwood, and walnut are the woods I’m printing. For the accent rings I just got a new material that I’m printing that has 40% copper, so its real metal that you can sand, and polish the same as wood filament. The stems are 3d printed as well. The concept is renewable and cheap from a production standpoint, with the ability to make a very high quality smoking pipe based on the experience.

By combining the calabash system pipe and bottom draft hole and using 3d simulations to see airflow, I can see where I’m having eddies and ripples in my current, and see where my moisture and all the particles are dropping back out from a vapor to a liquid. Most people who have tried these say the stems are clean, and they don’t even have to run a pipe cleaner afterward because everything collects at the bottom.

Chris has also been experimenting with color-changing plastics so you can see the hotspots. Chris said he was able to use this to slow down his cadence, which, of course, could mean you could get a slow-smoke training pipe to teach yourself to perform better.

If you’re interested in learning more or want to check one out, you can contact him on Instagram: Copper Beard Pipe Works

The Negative Space

The show was buzzing about one specific pipe, which had everyone guessing how it was made. I chatted with Adam Davidson briefly about it.

James: How did this idea come to fruition?

Adam Davidson: Smokingpipes.com had an expo back in August open to all of the makers they carry. The theme was to make a pipe utilizing bamboo. Given that the last time we had the expo I made a smooth Almond with three bamboo shanks, I challenged myself to do something different. I made three pipes for that expo and used bamboo on none of them. That’s when I came up with the idea to make a pipe specifically without bamboo and introduced negative space. We all see bamboo, but it is a void. It does not exist. The idea was pretty buzzy and I had a commission for another one, which is the piece I had in Vegas. I was happy to get the commission and the timing was perfect to allow so many people to see it in person and really be perplexed looking at it. When I developed the very first one, which is on SPC under sold display, it required a lot of backward thinking about how to actually do it. Many hours went into testing, experimenting, and failing.

James: And, of course, what you did is a trade secret?

Adam: This second one everyone saw in person was even more refined. Part of the enjoyment is hearing all of the theories about how I made it and so far no one has been correct, though some have been close, the details remain a secret. It was a lot of fun to show the piece off. The picture above shows Fernando smoking the pipe. Everyone loves Fernando, and he loves everyone. Perfectly fitting that a professional magician owns this pipe. He asked me how I did it. And I told him I would tell him if he would reveal his secrets to me. We both laughed and understood part of not understanding IS the magic.

Tobacco at the show:

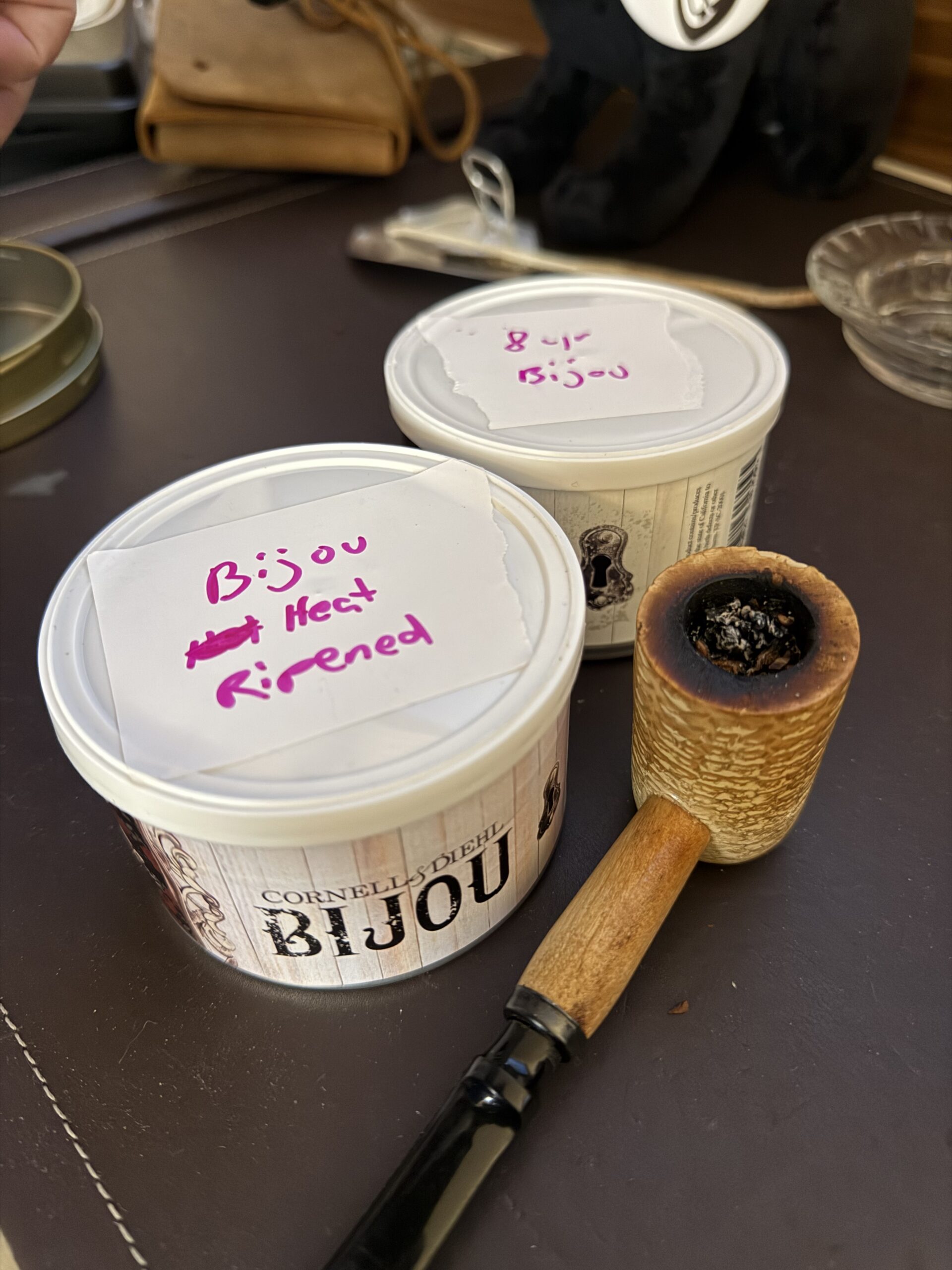

This year, Ken Byron KBV sent some tobacco to sample with an experiment.

KBV said he “heat ripened” the can of 2022 in an attempt to see if he can get close to the 2016 blend and asked for feedback. Both tins of Bijou feature 2003 vintage Eastern, North Carolina red Virginias with an estimated peak of 10-15 years. They are accented by bright leaf, rounded by small-leafed Katerini married with a hint of honey before being pressed and sliced into delicate flakes.

The 2016 tin, you can clearly see some appropriate aging and crystalization that you’d expect after eight years.

What you might notice in comparing these two tins is the cut of the flake is different, which was curious, so I went to the source and talked to Jeremy Reeves – who let me know the cutter they were using was replaced and impacted the look of the cut between the two tins.

Jeremy: A lot of times when people say heat ripened, they throw it in the oven at 200 degrees or leave it on the dashboard of the car. The recipe between the two has not changed, but we have had to swap out the internals of the cutters we’ve used. We’re still using the same leaf. My thing with heat ripening is that a lot of times I imagine they are killing off the microbes and years that would aid in fermentation – you’re getting the upfront sort of aromatic effect of aging but its not going to be as long lasting and you’re undoing the ability to carry on that fermentation process. Nothing more is going to happen but I’m not a microbiologist or scientist.

I next talked to the big brain and occasional writer here on pipesmagazine – Greg Pease who shared with me his post about this process, and as a blender doing this is not his bag but he has shared some insight into it.

There are many biological processes and chemical reactions going on in those tins, some of them simultaneous, some of them sequential, with the end products of one reaction being used to drive the next. Increasing the temperature will speed the rates of these reactions, but not necessarily linearly. That is, some reactions will speed up more than others, so the balance of what is going on in that little hermetically sealed laboratory can change dramatically with increased temperature. At or around normal room temperatures, we know pretty much what is going to happen, based on experience, but when it gets to the point where human beings become uncomfortable, things can really change.

This is not to say that heating tobacco is always a bad thing. Home stoving of straight virginias can, for instance, transform a monodimensional tobacco into something much more interesting. But, when dealing with mixtures, there’s a lot more involved, and some tobaccos just don’t want to be cooked. Too, it’s important to understand that these “stoving” methods are not a substitute for aging, nor is the actual, slow process of aging accelerated through these methods, though it certainly may be altered in an irreversible way. You wouldn’t put a fine bottle of wine in the oven to speed up its aging, would you?

So the results at the show was an 8-2 tally of those who preferred the original vintage 2016 tin vs the heat-ripened, younger 2022 tin. My own thoughts were the 2016 vintage tin smoked smoother, and because the fermentation muted the Virginias, you can pick up the more nuanced notes of the katerini, where the heat-treated had not quite muted the Virginias enough. I think more experimentation is in order.

Experiment Conclusion

Once all the speculation was done, I chatted with KBV and he stated he was really only looking for how the two compared, so the original ask may have been lost in translation. KBV says that this tin was not Stoved, it was kept at a basically warm summer temp to trigger fermentation at 120F in a heat drawer.

Show Dinner and Awards:

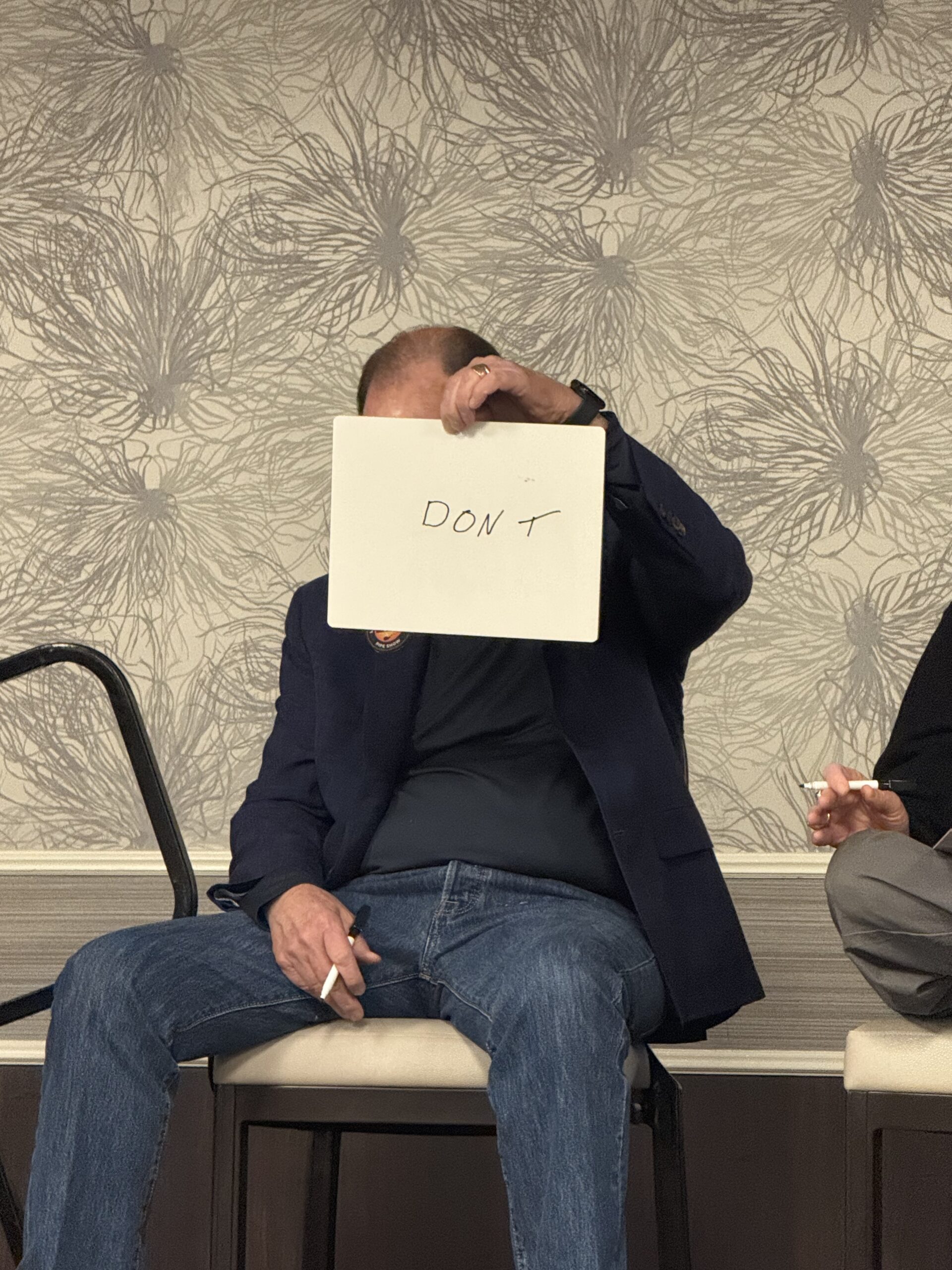

Like last year, this year’s dinner featured four awards given out by a super secret committee chosen to anonymously walk the show in search of Best in Show in several categories: Best Pipe, Best Commercial Display, Best Hobbyist Display, and Judges’ Choice. And similarly, Brian ran another gameshow of pipe-ictionary and another game of name that thing while blind-folded.

Grey (neon green) and Greg Pease (seated, right) decided to speak only like Christopher Walken during this process. Apparently, channeling the Walken can help.

Vera won the game this year, though, and it made for another funny year with some great food from The Palace Station.

Award Winners:

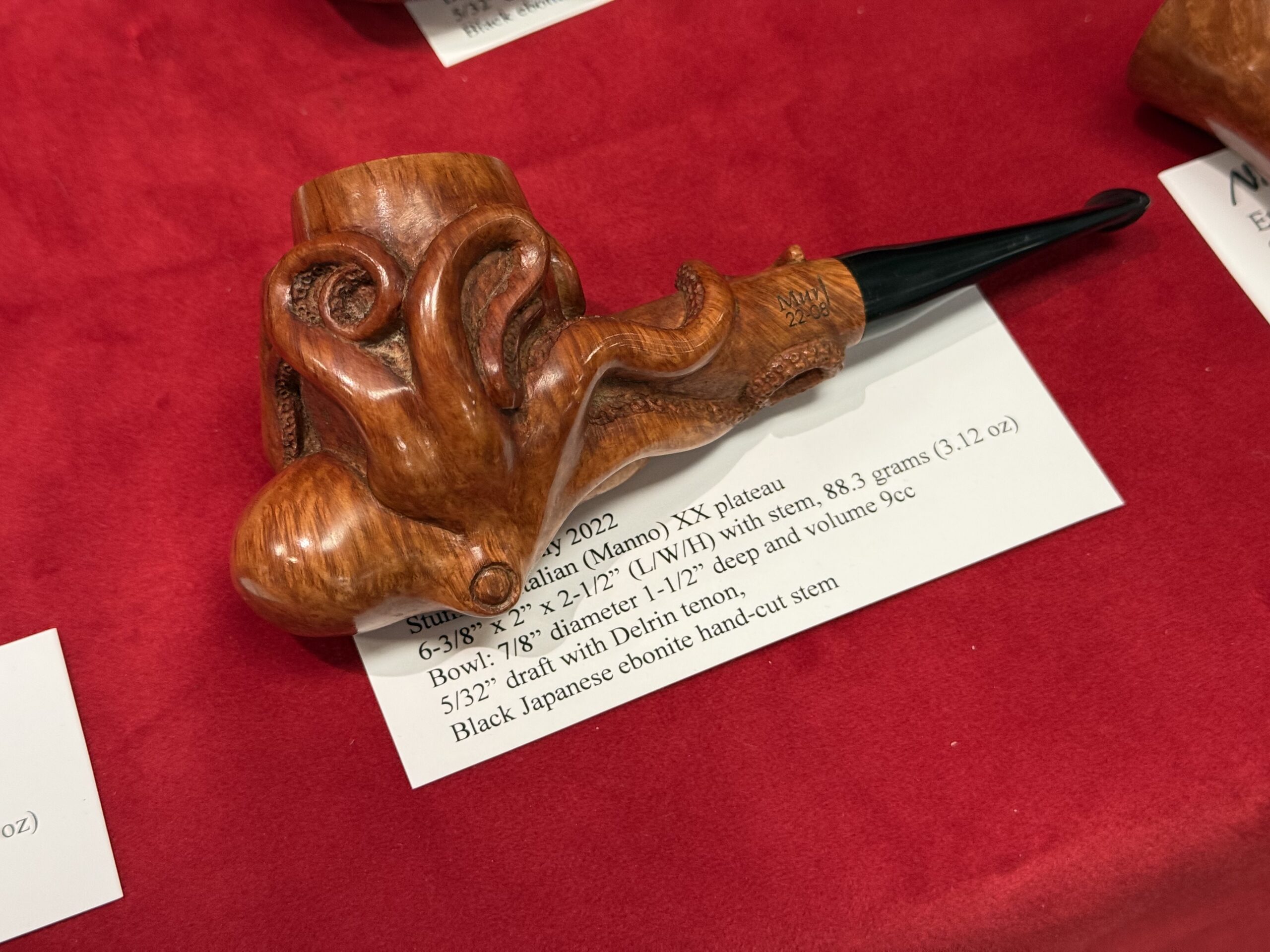

The best Pipe on Display winner was Brad Pohlmann

Best Commerical Display Winner was Meerschaum Market

Best Hobbiest Display Was Nate “Michael” King

Judges Choice Display: GH Zhang

Silver Grey thought it would also be nice to give Brian an “award” or gift based on his previous rants about not being able to smoke where he was, so now he’s got an umbrella hat to smoke in the sun and the rain.

Something Different…

I thought I’d share some more pictures of interesting and/or out of the ordinary pipes that I came across that were on display at the show.

Show Conclusions

Another great show in the books, seeing old friends, enjoying great food including In-N-Out, although not as much as some people….

I met some new young carveres that are promising and look forward to seeing what they can do in the future. We also got to see the cutting edge of 3D printed pipes, which might be something very cool to do for training for slow smokes. The Vegas International Pipe Show will return Oct 24th-26th, 2025, and pre-registration will be up in a couple of weeks. Vegas Pipe Show Website.

What’s next? I’ll be back down in Texas for the Texas Pipe Show on November 9th, the last pipe show of the year.