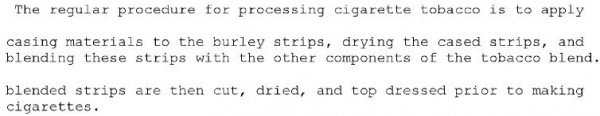

Concerning casing. I believe the most common ingredients in casings besides water to be licorice (licorice root extract, I do not know the amount) and cocoa at 05% to 1% weight (dutch processed cocoa or cocoa higher in cocoa butter content) Honey, Molasses or Fig, Date or Prune syrup can also be used. The casing should bring the total sugar in the blend to 10% tobacco weight. Casing is most likely where the humectant and other amendments will be added, humectants are generally added at about 2.5% to 4% of total tobacco weight. After the casing is applied the tobacco (tobacco should be about 40% moisture level) it is dried to about a 6% (in an oven perhaps) then moisture level is raised back to a 16% level, caramelizing some of the sugars in the heat/drying process (The sugary casing of the Burley is dried more than the none sugary casing of Virginias or Orientals.) (Licorice and Cocoa are important for Burley more than the other types of tobacco.)

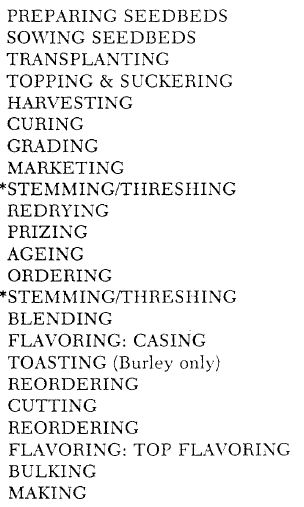

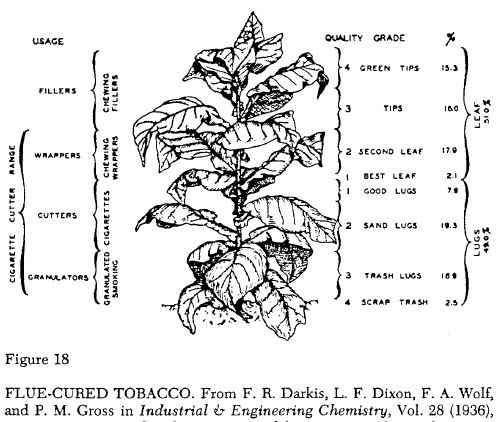

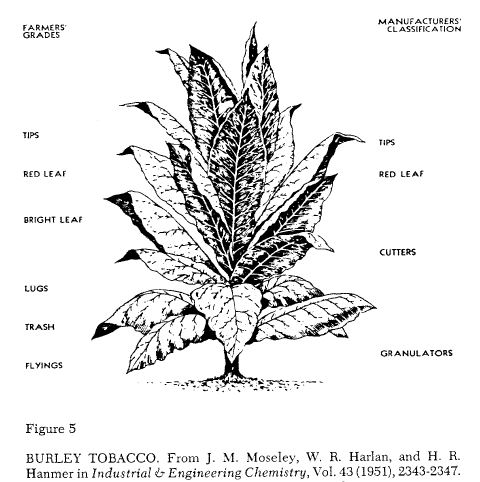

Here a couple pics that I found to be interesting. They are from document RDM 60-040 authored by J Keaton, L Upton in 1960

For those that want to case their own leaf it may be a good idea not to case your more aromatic leaves (Turkish for example) as it can reduce their aroma. Since Burley is naturally low in sugars the casing for it includes more sugars, if casing Virginias or Orientals much less sugar (about 1/3 of what is used on Burley) is used.

The casing is usually applied warm (120-180 degrees Fahrenheit) by a fine spray, this helps to keep the solutes in solution and may aid absorption. Then the cased tobacco is steamed to further open the tobacco pores thereby aiding absorption. The tobacco is then cooled to room temperature.

I thought this was a clever proposal.

Top Flavoring is usually a last step before packaging and is only used in very minute amounts. The art of subtlety is stressed so as to maintain the natural tobacco flavor. It is usually misted on via an alcohol solution. Top Flavoring is applied to the entire tobacco blend evenly, whereas casing can be different for each tobacco type. At least a week should pass before smoking flavored tobacco to allow for even flavor dispersal.

On a side note:

From my research into quality leaves, there is a direct correlation between total sugar content (up to 24% at the upper end) and smoke-ability of Flue-cured( Virginia) tobacco, with low sugar varieties being the worst. The quality is also impaired by low rainfall years (low rainfall=low sugar) and excess fertilizer application. Lower grade tobacco could be improved by the addition of sugar before aging, the aging process shows most of it's effects in the first two years, where the sugar content is naturally reduced (glucose is the sugar that changes significantly, sucrose changes a little bit, the other sugars not so much) in the process.

From what I have found out about harvesting; Burley was traditionally stalk harvested while Virginia and Orientals were traditional primed (hand picked leaves.) Virginias are Flue cured, Burleys are air cured and Orientals are sun cured. For the home grower in the U.S., air curing seems to be the most practical, and allow easy selecting of high quality leaves. In addition Burleys do better in richer soils and can benefit more from some fertilizer application. These attributes also seem to be better for the small scale home grower who has a small garden, with experience growing other garden plants that require good soil, fertilizer and watering. Growing a Burley, then curing, and casing seem like a simple task. Buying some quality flue cured Virginia, fire cured Kentucky, sun cured Oriental and Perique can then be mixed with your home grown Burley to which can be applied a Top Flavoring if you desire to finish of your homemade blend.