I imagine the factory has ten different jigs they use for cutting and finishing panels. And even so, some are better than others. I would not want to try one freehand.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Also, what was the purpose of the step cuts on the old English tenons?

'Tis a mystery.

I've never talked to anyone who actually knows. Steps were commonly found on many British factory brands, as well.

Best guess is it's simply an artifact of the tooling used to cut tenons at the factories which produced them that way, such as a hollow mill; or some indexing procedure the workers were told to do.

Taking the liberty of expanding beyond four square to six squared. Four square is a Castello shape 33. The six-paneled billiard by Rainer Barbi is absolutely brilliant work. The stummel tapers towards the rim and the center ridge carries through the shank and stem. Very lucky to win this on recent eBay auction. I've included multiple photos from the listing to show off Barbi's virtuosity.

A very good question indeed. I've panelled round pipes, and I've started square and done the "rounding" at a later stage, and ... probably... probably that's a little bit easier. It's very weird though to take a block of briar, run it this way and that way, and another, and like this and NOW ... now it's ready for 5 minutes on the lathe.What I've wondered about this shape is: do they turn a billiard then flatten the sides or cut the four faces then round the corners?

A

AroEnglish

Guest

Yeah I can imagine how odd that would feelA very good question indeed. I've panelled round pipes, and I've started square and done the "rounding" at a later stage, and ... probably... probably that's a little bit easier. It's very weird though to take a block of briar, run it this way and that way, and another, and like this and NOW ... now it's ready for 5 minutes on the lathe.

A

AroEnglish

Guest

I know @tfdickson and @solideogloria86 have some from Ryan Alden.

@sasquatch has done at least one that I've seen.

@TheIronMonkey do you have an 502, 506, or 515 pipes in your collection?

Yep, I have a couple of 4 squares from Alden, a smooth and a blast.

I always thought they were for a better tenon/mortise fit. I must have read something about it somewhere, but I don't remember.Also, what was the purpose of the step cuts on the old English tenons?

I'll tell you my opinion: the panel was born (like other shapes, especially free hand) in an attempt to avoid the imperfections of the briar.What I've wondered about this shape is: do they turn a billiard then flatten the sides or cut the four faces then round the corners?

Just as you cut off a slice of a rotten apple (and you don't throw away the whole apple), so someone, one day, after having made a Billiard, noticed an imperfection on the briar and decided to cut off a slice hoping to find the smooth underneath. Then, to even out and give symmetry to the whole, he also cut the other three sides.

Then, over time, it became a shape

My two million dollars.

I have a couple 'flat-edgers'.

These are new-to-me Estates which I have not cleaned up yet, so no judging...

First one (in the middle actually) is the true 4-panel - a Savinelli de luxe 515.

The lower one is a Kaywoodie Drinkless 6-panel 7781C.

I know its not a 4-panel so I make up for this with the one on top - which is 2 flat and two curved...

a Kaywoodie Super Grain 5122C.

And to answer the great debate of why make a 4-panel pipe, it is so you can smoke two at a time and they stabelize each other. This allows endless custome blends. Obviously this works better with the same size/shape pipe but we make due.

These are new-to-me Estates which I have not cleaned up yet, so no judging...

First one (in the middle actually) is the true 4-panel - a Savinelli de luxe 515.

The lower one is a Kaywoodie Drinkless 6-panel 7781C.

I know its not a 4-panel so I make up for this with the one on top - which is 2 flat and two curved...

a Kaywoodie Super Grain 5122C.

And to answer the great debate of why make a 4-panel pipe, it is so you can smoke two at a time and they stabelize each other. This allows endless custome blends. Obviously this works better with the same size/shape pipe but we make due.

A

AroEnglish

Guest

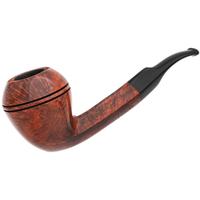

Here's a pretty neat one from Martin Cermak