Would look nice in neon orange. Or original tiger stripes. Desert tiger's cool too.

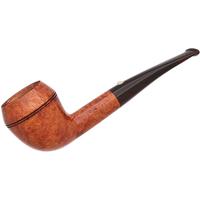

Original Stain... Or Not?

- Thread starter torthur

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

I'm with Jessie on this reply.If it's not a "collectible" pipe, go and knock yourself out! If you care about market value on a collectible pipe, then "restoration" should be done as discreetly as possible.

@Ahi Ka come tell the Peterson Lacquer story!

how hard did you run into it?

I own over a hundred Lee pipes, and the early ones, if stained, the stain is so deep it can’t be removed with steel wool. Lee must have boiled the briar in a stain.Good morning y'all.

Just wondering.

What is your approach when restoring a pipe?

Do you try to maintain the original painting at any cost, or do you change the pipes dramatically to your liking?

I am thinking here of pipes for personal use, not for sale.

With lesser quality pipes it’s usually easy to remove the stain, which often then reveals flaws.

I’ll need to find the thread. Secret Santa is clogging up my notifications.@Ahi Ka come tell the Peterson Lacquer story!

@telescopes is gonna have a field day with thisLee must have boiled the briar in a stain.

Ha ha.@telescopes is gonna have a field day with this

A little while back somebody who restores pipes tried to remove the stain from a Lee. It took a lot of sandpaper and elbow grease and he declared he’d not do that again.@telescopes is gonna have a field day with this

A Lee was a production line product. You see video of Dunhill workers firing off stain between stainings, and my bet is Lee had a better and faster staining system. However he did it, the early stained ones are stained extremely deep.

On the very late stamped star Lees, the stain comes off easily with steel wool. The very last Lees abandoned the screw stem in favor of the cheaper common push stem, as well.

But even the last Lees have a distinctive sweet flavor while breaking in.

Briar Lee, please, please stop acting coy!

You know why the stain is so deep on those "Pipes by Lee". It is because of the porosity of the briar he used.

You know why the stain is so deep on those "Pipes by Lee". It is because of the porosity of the briar he used.

Ruminations on the Porosity of Briar

@Ahi Ka

This one?

Another thing learned. Dump in acetone for a little while. I was also rubbing with soaked cloth. Thanks!

This one?

Thoughts On Modifying The Finish Of A Peterson Rosslare Royal Irish Sanblast :: Pipe Talk

Lads, I recently got this pipe from our resident Santa @klause, it is probably my best smoking briar to date. The only thing that doesn’t tickle my fancy is the thick lacquer type finish of/over the blast. Just musing as to how one would go about removing some of this to let some of the briar...

pipesmagazine.com

Another thing learned. Dump in acetone for a little while. I was also rubbing with soaked cloth. Thanks!

Yep that’s the one! I used a small container which would hold the pipe snug in the direction I wanted it. This meant that the damp cloth soaked in acetone would only tackle one section at a time.

I’m actually thinking about stripping the stain off this Pete completely at some stage.

I’m actually thinking about stripping the stain off this Pete completely at some stage.

I found the thread where the guy took a Dremel tool to a Lee Three Star:Briar Lee, please, please stop acting coy!

You know why the stain is so deep on those "Pipes by Lee". It is because of the porosity of the briar he used.

Ruminations on the Porosity of Briar

Sometimes They Fight Back. A Lee 3-star :: Pipe Repair and Maintenance

When I received this pipe I expected a simple clean-up and polish. No apparent damage to the stem or rim is a good sign. First step is to clean it up. My practice is to take it to the sink, give it a few squirts of full-strength AWESOME, and scrub it with a soft toothbrush--inside and...

pipesmagazine.com

The reason Lee had his own pipe company which in the day sold the most expensive factory pipes on earth and I never will, is Lee was a complete genius on how to make pipes and I’m not, nor ever will be.

Lee pipes came in a statin finish, not glossy like a cheap polyester suit.

If a Lee was stained (only some of the cheaper grades were below Four Star) the stain also served to fill pits and pores in the briar.

How De Do Dat?

Stain will never "fill pits and pores" (puty fills), darker stains can make a pit/pore/flow be less noticeable.If a Lee was stained (only some of the cheaper grades were below Four Star) the stain also served to fill pits and pores in the briar.

How De Do Dat?

When it comes to "original stain" - most of us do not have the materials to properly match the stain of a collectible factory pipe. We can get close. I keep four stains on hand:

- black

- Medium Brown

- Dark Brown

- Burgundy

I can mix those to APPROXIMATE a factory stain.

George D once told me that he has close to 100 stains (I think it was that number), which allows him to PERFECTLY match a collectible factory stain. If I know George, he has "recipes" on how he does that for the various factory finishes.

I'm not sure anyone else has that level of detail to match a factory stain.

If it weren’t on the edge, cyno with briar dust might be something to use. Given you’re dealing with an edge, briar dust with epoxy could work—you’d have to roughen the surface so the epoxy can grip, build it up, and gently file down after curing. @georged would have a better solution.Hey,

I wont make another topic, but I'll put my restoration adventures in here.

I'm during work on couple of pipes, and I have a question.

View attachment 175153

Do any of you know how can I fill this gap?

I've experimented with some putty, but it keeps chipping off.

Epoxy is a good idea, but I don't have any on hand (another thing I need to buy).If it weren’t on the edge, cyno with briar dust might be something to use. Given you’re dealing with an edge, briar dust with epoxy could work—you’d have to roughen the surface so the epoxy can grip, build it up, and gently file down after curing. @georged would have a better solution.

I've decided to sand it down. Little bit shorter, but no worries

George has a you-tube video on this solution, it doesn't involve glue, but rather properly creating two new surfaces that mate.If it weren’t on the edge, cyno with briar dust might be something to use. Given you’re dealing with an edge, briar dust with epoxy could work—you’d have to roughen the surface so the epoxy can grip, build it up, and gently file down after curing. @georged would have a better solution.

Have a link for that?George has a you-tube video on this solution, it doesn't involve glue, but rather properly creating two new surfaces that mate.

May be usefull in the future.

High Grade Pipe Repair & Restoration is his YouTube channel.Have a link for that?

May be usefull in the future.