Well said. Thank you.Yup. ^^^^

Sorry you got took.

You're not alone, though. Dealing with "magic" products as a categorical thing is like trying to fill the Grand Canyon with a shovel. People will always believe whatever makes them feel good and to hell with reality.

(For a good example of how far it can go, look up "Zenu" and prepare to be amazed.)

Regarding vulcanite pipe stem surface oxidation, the facts are these:

The INTENDED market for gel deoxidizers is filigree-etched fountain pen barrels, because sanding them is not possible without destroying the thing you're trying to save. Do they work for that application? As much as anything can. The amount of oxidized material they eat away varies from specimen to specimen. (Besides, it doesn't matter since any improvement is better than none.)

Using such gels on a smooth object like a pipe stem, though, is pointless. They are expensive, time consuming, messy, and result in something that MUST STILL BE SANDED BACK TO SMOOTH NO MATTER HOW WELL IT WAS "DE-GREENED", because the chemical leaves a textured surface behind. So why not just sand it to begin with?

The End

My Experience with Lbepen Deoxidizer [with pics]

- Thread starter SBC

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

there is still oxidation inside the material that would need to be removed by sanding

why not just sand it to begin with?

Good to see both views of this product. I've not tried it (though I may) because it seems expensive to me, especially if it often only works about as well as Oxi-clean. My limited experience has shown me that if I really want the stem to look nice (so I'm comfortable selling it), I'll usually need to sand and use micromesh.I can say with confidence that this works for all practical purposes

Since my last post, I have tried to salvage the stems I used this product on and have come to the decision that there is no way I will ever use it again. On a stem that I used this product on, it had the appearance of being matte black. There are some deep depressions and a small hole from chatter that i needed to fill. I filled the hole and then sand the area to smooth the surface. The sanding revealed that there was plenty of oxidation beneath the surface that this product was covering. Once I thought I sanded enough to remove the layer of oil, I soaked it in oxiclean to try to remove the rest of the remaining oxidation. Unfortunately, the product soaked far enough into the vulcanite to where the oxiclean couldn't get to all the oxidation. The remaining oxidation had to be removed mechanically. I wound up removing way more material and taking 5 times as long than if I used the oxiclean and/or sanding technique.Good to see both views of this product. I've not tried it (though I may) because it seems expensive to me, especially if it often only works about as well as Oxi-clean. My limited experience has shown me that if I really want the stem to look nice (so I'm comfortable selling it), I'll usually need to sand and use micromesh.

Your experience is correct. The only way to remove oxidation is to REMOVE the oxidation with sanding. I would never sell a pipe after using this product. The black finish will wear after smoking, questionable safety and it will not produce the glossy black shine you have come to expect.

I have thrown my bottle in the trash and chalked it up to experience.

Since my last post, I have tried to salvage the stems I used this product on and have come to the decision that there is no way I will ever use it again. On a stem that I used this product on, it had the appearance of being matte black. There are some deep depressions and a small hole from chatter that i needed to fill. I filled the hole and then sand the area to smooth the surface. The sanding revealed that there was plenty of oxidation beneath the surface that this product was covering. Once I thought I sanded enough to remove the layer of oil, I soaked it in oxiclean to try to remove the rest of the remaining oxidation. Unfortunately, the product soaked far enough into the vulcanite to where the oxiclean couldn't get to all the oxidation. The remaining oxidation had to be removed mechanically. I wound up removing way more material and taking 5 times as long than if I used the oxiclean and/or sanding technique.

Your experience is correct. The only way to remove oxidation is to REMOVE the oxidation with sanding. I would never sell a pipe after using this product. The black finish will wear after smoking, questionable safety and it will not produce the glossy black shine you have come to expect.

I have thrown my bottle in the trash and chalked it up to experience.

I’m sorry you had less than satisfactory results. I’ve used it to good effect and will likely buy more.

LikewiseI’m sorry you had less than satisfactory results. I’ve used it to good effect and will likely buy more.

I recently bought some of this stuff and I had the same results concerning the light matte finish. If you go to the stems in OP's picture you can see the matte in those stems too. I've done 10 stems so far, most had very light oxidation, mostly lightly around where the lips go. I pulled them out and they did pull off an impressive amount of the brown gunk. And then I went to do the micromesh work and I was getting brown on the pads, which I didn't get before. So I went back with my magic eraser and toothpaste and more oxidation came off. Not a ton but enough. The remaining oxidation on the stem seemed to be softer and stickier, making it harder to get it off. I resorted to light sanding using 600 or 800 grit.

I tried toasting it with a lighter as suggested here, but that didn't help. I haven't used it on a really heavily oxidized pipe, so maybe it's great on caked up oxidation but on lightly oxidized stems it's not worth it for me. I don't know but I'm going to hold off using it again until I get a really caked stem to try it on.

The manufacturer makes a good point on soaking vulcanite stems in oxyclean and water- as the rust is from moisture (most of the oxidation is in the lip area, right?). So he argues to keep stems from touching water. So I'm not sure if oxy soaks are a good thing now.

I tried toasting it with a lighter as suggested here, but that didn't help. I haven't used it on a really heavily oxidized pipe, so maybe it's great on caked up oxidation but on lightly oxidized stems it's not worth it for me. I don't know but I'm going to hold off using it again until I get a really caked stem to try it on.

The manufacturer makes a good point on soaking vulcanite stems in oxyclean and water- as the rust is from moisture (most of the oxidation is in the lip area, right?). So he argues to keep stems from touching water. So I'm not sure if oxy soaks are a good thing now.

When you have a finished stem, you can have water on it all day long and the stem is fine. I wet sand my stems (using water) with glorious results. In my opinion, the manufacturer says to keep stems away from water because after his treatment, when you get the stem wet, you will be able to see the oxidation that is remaining. Which is what happens on an oxidized stem. Get it wet with anything, water or 91% alcohol, and you can see remaining oxidization. When you remove the oxidation, getting the stem wet shows a jet black stem.I recently bought some of this stuff and I had the same results concerning the light matte finish. If you go to the stems in OP's picture you can see the matte in those stems too. I've done 10 stems so far, most had very light oxidation, mostly lightly around where the lips go. I pulled them out and they did pull off an impressive amount of the brown gunk. And then I went to do the micromesh work and I was getting brown on the pads, which I didn't get before. So I went back with my magic eraser and toothpaste and more oxidation came off. Not a ton but enough. The remaining oxidation on the stem seemed to be softer and stickier, making it harder to get it off. I resorted to light sanding using 600 or 800 grit.

I tried toasting it with a lighter as suggested here, but that didn't help. I haven't used it on a really heavily oxidized pipe, so maybe it's great on caked up oxidation but on lightly oxidized stems it's not worth it for me. I don't know but I'm going to hold off using it again until I get a really caked stem to try it on.

The manufacturer makes a good point on soaking vulcanite stems in oxyclean and water- as the rust is from moisture (most of the oxidation is in the lip area, right?). So he argues to keep stems from touching water. So I'm not sure if oxy soaks are a good thing now.

I used it on a heavily oxidized stem and I feel the more oxidation, the harder it is to correct it after this treatment. If you want to try it on a heavy oxidized stem, don't do it on a valuable pipe just in case.

I’d be interested in reviews on the Briarville product. Probably much the same, and perhaps a little stronger. I believe the solution is fine for fountain pens and saving the clementure (on fountain pens only). I’ve always done an oxy soak with Vaseline on logos, then sanding with sandpaper and moving to micromesh. Lots of obsidian oil between pads.

A positive from Labelle is the restoration wax, and the super fine polish.

A positive from Labelle is the restoration wax, and the super fine polish.

George, do you think the textured surface is caused by the cleaner, or by the oxidation?Yup. ^^^^

Sorry you got took.

You're not alone, though. Dealing with "magic" products as a categorical thing is like trying to fill the Grand Canyon with a shovel. People will always believe whatever makes them feel good and to hell with reality.

(For a good example of how far it can go, look up "Zenu" and prepare to be amazed.)

Regarding vulcanite pipe stem surface oxidation, the facts are these:

The INTENDED market for gel deoxidizers is filigree-etched fountain pen barrels, because sanding them is not possible without destroying the thing you're trying to save. Do they work for that application? As much as anything can. The amount of oxidized material they eat away varies from specimen to specimen. (Besides, it doesn't matter since any improvement is better than none.)

Using such gels on a smooth object like a pipe stem, though, is pointless. They are expensive, time consuming, messy, and result in something that MUST STILL BE SANDED BACK TO SMOOTH NO MATTER HOW WELL IT WAS "DE-GREENED", because the chemical leaves a textured surface behind. So why not just sand it to begin with?

The End

George, do you think the textured surface is caused by the cleaner, or by the oxidation?

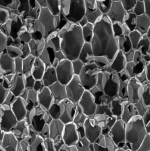

Vulcanite / Ebonite looks smooth and uniform, but it's not. It's composed of little balls that have been squashed together. Think styrofoam with harder & smaller particles.

The smallest unit that can be dissolved chemically is one of the "beads".

Result? When a liquid comes along that attacks oxidation, only the beads which are oxidized get dissolved, and those which are not oxidized remain whole, regardless of their position relative to each other. And because position in a matrix that has been squashed together is random, a smooth, shiny, and level surface never happens. It can't happen.

Slice the little buggers horizontally by mechanical means, though, and it's a different story. Some of the beads are still 90% there, and others only 10%. Some 34.7% there, and others 62.5% gone. Etcetera. The peaks are lowered and the crevices filled.

So…yes. Oxidation causes pitting?Vulcanite / Ebonite looks smooth and uniform, but it's not. It's composed of little balls that have been squashed together. Think styrofoam with harder & smaller particles.

View attachment 252618

The smallest unit that can be dissolved chemically is one of the "beads".

Result? When a liquid comes along that attacks oxidation, only the beads which are oxidized get dissolved, and those which are not oxidized remain whole, regardless of their position relative to each other. And because position in a matrix that has been squashed together is random, a smooth, shiny, and level surface never happens. It can't happen.

Slice the little buggers horizontally by mechanical means, though, and it's a different story. Some of the beads are still 90% there, and others only 10%. Some 34.7% there, and others 62.5% gone. Etcetera. The peaks are lowered and the crevices filled.

So…yes. Oxidation causes pitting?

Better to say that in the case of vulcanite, pitting is caused by oxidation.

Because there are other materials that can be oxidized but NOT have pits. The metal of blued firearms, for example. The bluing (also browning) is 100% oxidation.

If this gel actually has chemically de-oxidizing properties it should be the best option for regular maintenance of vulcanite stems.Yup. ^^^^

Sorry you got took.

You're not alone, though. Dealing with "magic" products as a categorical thing is like trying to fill the Grand Canyon with a shovel. People will always believe whatever makes them feel good and to hell with reality.

(For a good example of how far it can go, look up "Zenu" and prepare to be amazed.)

Regarding vulcanite pipe stem surface oxidation, the facts are these:

The INTENDED market for gel deoxidizers is filigree-etched fountain pen barrels, because sanding them is not possible without destroying the thing you're trying to save. Do they work for that application? As much as anything can. The amount of oxidized material they eat away varies from specimen to specimen. (Besides, it doesn't matter since any improvement is better than none.)

Using such gels on a smooth object like a pipe stem, though, is pointless. They are expensive, time consuming, messy, and result in something that MUST STILL BE SANDED BACK TO SMOOTH NO MATTER HOW WELL IT WAS "DE-GREENED", because the chemical leaves a textured surface behind. So why not just sand it to begin with?

The End

If this substance has any ability to reverse oxidation then if used regularly your vulcanite stems will last forever (as opposed to any form of polishing which is abrasive and therefore guaranteed to destroy the stem over time).

If this gel actually has chemically de-oxidizing properties it should be the best option for regular maintenance of vulcanite stems.

It costs $412.50 per gallon.

Anyone determined to go the liquid route can use common chlorine bleach.

You do the math.

If this substance has any ability to reverse oxidation then if used regularly your vulcanite stems will last forever (as opposed to any form of polishing which is abrasive and therefore guaranteed to destroy the stem over time).

It has no ability whatsoever to reverse oxidation. NO chemical does.

Oxidation is a change in the structure of a material at the atomic level. A loss of electrons. It's a one way street.

Same. Using OxyClean and it works well. Incredible the difference after some post Oxy sanding and some obsidian oil. Feel like a master restorer!Seems to have done a nice job, and by the way, nice pipes. I use OxyClean on my stems and it does a decent job. I may have to do some rubbing afterwards but not much. My stems don't have to shine on a moonlit night but I don't like them looking too crappy. Nice job.

I cannot recommend this deoxidizer. This product is made for fountain pens. The fact that it is being used for pipe stems is an off shoot. @georged has mentioned is correct.

I can recommend the restoration balm which is water friendly, and the two grits of pipe polish.

There just isn’t any magic solution. My process involves a quick soak in oxyclean and water. Not a long time, just enough to notice some brown color. I also use silicone grease rather than Vaseline on any hallmark. The grease is very sticky. After oxyclean is use a fine steel wool.

Then some soft scrub, and some of the white sponges, then sanding. Don’t spare the obsidian oil. If not avail try some mineral oil. But use obsidian when your pipe is resting.

We do have great products to prevent oxidation to some extent. Once the stem is clean and shiny use obsidian to keep it that way.

I have not used the Briarville product, but many are using it with success.

I can recommend the restoration balm which is water friendly, and the two grits of pipe polish.

There just isn’t any magic solution. My process involves a quick soak in oxyclean and water. Not a long time, just enough to notice some brown color. I also use silicone grease rather than Vaseline on any hallmark. The grease is very sticky. After oxyclean is use a fine steel wool.

Then some soft scrub, and some of the white sponges, then sanding. Don’t spare the obsidian oil. If not avail try some mineral oil. But use obsidian when your pipe is resting.

We do have great products to prevent oxidation to some extent. Once the stem is clean and shiny use obsidian to keep it that way.

I have not used the Briarville product, but many are using it with success.

Last edited:

Products which remove the sulphur deposits resulting from oxidation and leave unoxidized vulcanite unaffected will ultimately leave microscopic pits in the surface which were previously filled with sulphur. This is because at a microscopic level, oxidation does not happen evenly across the surface. Georged's explanation of this earlier is superb.

Once deoxidized by chemical means, the vulcanite is like a wooden board freshly cut at the sawmill. Yes, it's fairly smooth, but there is little argument that sanding with progressively finer grades of sandpaper or planing with a sharp blade will make the surface even smoother. These methods do not smooth the wood by flattening or compressing the material, but by removing material which forms tiny ridges until a uniform surface is achieved.

I think which side of the "It's Shiny" fence you land on is dependent upon your personal standards for the condition of your vulcanite stems.

If you just want your stems black and free of ugly, bitter oxidation, and are unconcerned about how shiny or smooth they are, then a quality chemical deoxidizer sounds like a great, low-effort solution.

If you like them blacker and glossier, then chemically removing the oxidized material from the surface and applying something like mineral oil to temporarily deepen the color and provide a bit of shine and protection is perfectly adequate.

If you like them even shinier, then adding an intermediate step of buffing the stem before oiling will get you there. Another option is to use a polish, like the one sold by the manufacturer of the deoxidizer.

If you like them to be like-new smooth, shiny, and deep black as I do, then the reality is that all products which remove surface oxidation while leaving vulcanite unaffected will be relatively useless. In order to achieve a deep black and brilliantly shiny and smooth surface, the surface must be free of the microscopic pits formerly occupied by sulphur left behind by oxidation. This means removing the unoxidized vulcanite that surrounds those pits so that the outer surface of the stem is evenly unoxidized rubber which was below the level of the pits. This is achieved only by abrading the entire surface. So, using a product which removes the oxidation while leaving behind microscopic pits doesn't help very much. For me, that would be a wasted step since sanding will simultaneously remove both the sulphur deposits and unoxidized rubber which surrounds those deposits. There may be an argument for using an oxidation remover for places where sanding is more challenging, like right behind the button.

Once deoxidized by chemical means, the vulcanite is like a wooden board freshly cut at the sawmill. Yes, it's fairly smooth, but there is little argument that sanding with progressively finer grades of sandpaper or planing with a sharp blade will make the surface even smoother. These methods do not smooth the wood by flattening or compressing the material, but by removing material which forms tiny ridges until a uniform surface is achieved.

I think which side of the "It's Shiny" fence you land on is dependent upon your personal standards for the condition of your vulcanite stems.

If you just want your stems black and free of ugly, bitter oxidation, and are unconcerned about how shiny or smooth they are, then a quality chemical deoxidizer sounds like a great, low-effort solution.

If you like them blacker and glossier, then chemically removing the oxidized material from the surface and applying something like mineral oil to temporarily deepen the color and provide a bit of shine and protection is perfectly adequate.

If you like them even shinier, then adding an intermediate step of buffing the stem before oiling will get you there. Another option is to use a polish, like the one sold by the manufacturer of the deoxidizer.

If you like them to be like-new smooth, shiny, and deep black as I do, then the reality is that all products which remove surface oxidation while leaving vulcanite unaffected will be relatively useless. In order to achieve a deep black and brilliantly shiny and smooth surface, the surface must be free of the microscopic pits formerly occupied by sulphur left behind by oxidation. This means removing the unoxidized vulcanite that surrounds those pits so that the outer surface of the stem is evenly unoxidized rubber which was below the level of the pits. This is achieved only by abrading the entire surface. So, using a product which removes the oxidation while leaving behind microscopic pits doesn't help very much. For me, that would be a wasted step since sanding will simultaneously remove both the sulphur deposits and unoxidized rubber which surrounds those deposits. There may be an argument for using an oxidation remover for places where sanding is more challenging, like right behind the button.

Last edited:

This thread was started by someone trying to sell their Lbepen goop-stuff which was designed for etched and otherwise textured pen barrels made from ebonite to a new market. A group of people who also have small personal items of value that turn green from neglect, age, use, etc. Namely, us.

It works as intended on textured-surface pen barrels just fine. (As well as anything can given the nature of the problem, anyway, where sanding/polishing will destroy the designs.)

It works equally well on ebonite pipe stems. The problem being that THAT is an incomplete solution because pipe stems are supposed to be glassy smooth... and the goop-stuff leaves them finely textured. i.e. Matte. Not shiny.

So more work is needed to make them shiny. Some form of sanding and polishing.

Which is something that could have been done at the start, taken no more time, and cost (effectively) nothing... instead of $400+ per gallon, plus hours of waiting and messing about with tubs, trays, jars, and timers.

That is it.

The entire story.

It works as intended on textured-surface pen barrels just fine. (As well as anything can given the nature of the problem, anyway, where sanding/polishing will destroy the designs.)

It works equally well on ebonite pipe stems. The problem being that THAT is an incomplete solution because pipe stems are supposed to be glassy smooth... and the goop-stuff leaves them finely textured. i.e. Matte. Not shiny.

So more work is needed to make them shiny. Some form of sanding and polishing.

Which is something that could have been done at the start, taken no more time, and cost (effectively) nothing... instead of $400+ per gallon, plus hours of waiting and messing about with tubs, trays, jars, and timers.

That is it.

The entire story.