Looking For Someone To Restore My Dunhill

- Thread starter zerohunter

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Watch for Updates Twice a Week

- Status

- Not open for further replies.

I picked one up for 20 bucks shipped on ebay a few years ago but it was from the 70's. You are lucky and I'm a bit jealous.

No need, actually, cuz I'mma gonna do it. :mrgreen:I will post pics once George restores it!

After deciding to let your pipe through the door, I further decided to go all in by letting it jump the queue as well.

It's my Summer Insanity moment, I guess. :lol:

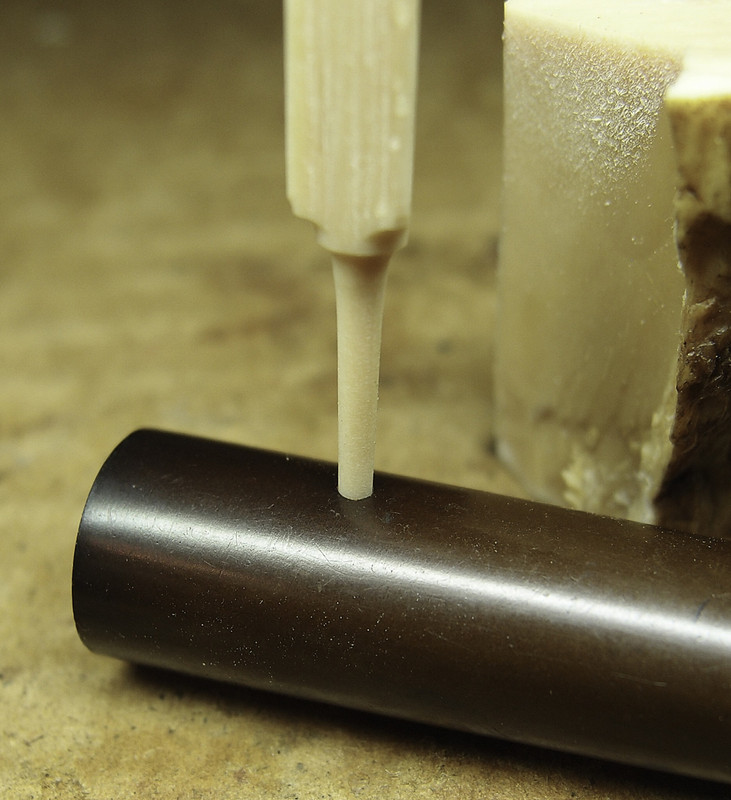

And work is already underway. The first order of business was replacing the dot before getting the stem back to black. That way it could be leveled at the same time the oxidation was removed.

(The reason the original dot fell out/dissolved, btw, is because the hole it was glued into cut through to the interior of the stem where tar & etc. could attack it. Real ivory was used back then, and it wicks moisture and smoke acids. Over time dots so exposed will turn black and eventually crumble away.)

To keep it from happening again---I used real ivory for the new dot---the bottom of the hole was sealed with a bit of epoxy.

Here are the steps completed so far.

(More to follow over the next couple days)

I've never seen George so excited about a restore. Break out the popcorn, this is going to be good!

Holy moly, George, that looks amazing already! And I had no idea Dunhill used to use ivory for the dot. It's a restoration and a history lesson in one. I love it!

---- Behind the Scenes, Part 2 ----

The state of the pipe was unusual. It had been heavily smoked for many years, but was then put away and not smoked again for many more. We're talking fossilized cake, DEEP stem oxidation and acidic corrosion, and a completely closed shank and airway. And the little fiber tube that's part of the Vernon design had both ossified and fused into its surroundings. That said---and what makes the pipe unusual---is that under all the crud and neglect there was very little actual damage. Though massively smoked it was done with care. No stem chewing, chamber burning, pipecleaner ram-rodding, dings, dents, or cracks.

Except for the rim having been knocked enough to radius the edge with thousands of little taps over many years, there was still a wonderful pipe "in there."

.

.

.

.

The first order of business for the stummel was clearing the airway with a succession of specially-shaped drill bits to avoid bending/twisting the Vernon spring fingers. Straightforward but slow going because that little bastard was like stone, and jacking the fitment would have been a disaster. Nothing to see process-wise, though, so no photos taken.

Ditto the chamber walls. Massively thick, ceramic-hard cake all the way to the heel, but aside from taking care to not go too far---a real danger with ancient pipes---nothing worth a picture.

Then came the rim. The carbon was chipped off to check the state of the wood underneath, and sure enough, as already mentioned, it had been gently hammered round. Very evenly, though, so hardly any wood had to be removed to get back to flat, level, and sharp-edged. Slightly less than a millimeter. Not enough to affect the profile of the pipe, IMO.

For maximum authenticity, I used a pipe from my own rack that was the same size, shape, make, grain orientation, finish, and from the same production period to as a model for cutting the new rim. A pattern, if you prefer. Surprisingly, the profiles DO differ. Normal-wall-thickness Shells from this period are actually chamfered inward a few degrees. (re-sandblasting doesn't work, btw, for too many reasons to go into here. Just trust me when I say this sort of situation requires cutting by hand.)

Here are the two side by side:

.

And here is the result:

.

The stem was then de-greened with the usual parade of files and abrasives to get it back to black.

Here's where the pipe stands at the moment:

.

There was a catch to the de-greening, though. The oxidation was so thick---one of the ten worst cases I've seen---that AFTER it was removed, the stem was slightly smaller all over. Meaning (mostly) diameter. Meaning no longer level with the end of the shank when the two are put together: 8O

Oh No!!!! :twisted:

Will Ming the Merciless finally dispatch Buck and conquer the Universe? Or will he fight back and Truth, Justice, and the American Way will emerge victorious?

You'll have to tune in tomorrow to find out. :mrgreen:

The state of the pipe was unusual. It had been heavily smoked for many years, but was then put away and not smoked again for many more. We're talking fossilized cake, DEEP stem oxidation and acidic corrosion, and a completely closed shank and airway. And the little fiber tube that's part of the Vernon design had both ossified and fused into its surroundings. That said---and what makes the pipe unusual---is that under all the crud and neglect there was very little actual damage. Though massively smoked it was done with care. No stem chewing, chamber burning, pipecleaner ram-rodding, dings, dents, or cracks.

Except for the rim having been knocked enough to radius the edge with thousands of little taps over many years, there was still a wonderful pipe "in there."

.

.

.

.

The first order of business for the stummel was clearing the airway with a succession of specially-shaped drill bits to avoid bending/twisting the Vernon spring fingers. Straightforward but slow going because that little bastard was like stone, and jacking the fitment would have been a disaster. Nothing to see process-wise, though, so no photos taken.

Ditto the chamber walls. Massively thick, ceramic-hard cake all the way to the heel, but aside from taking care to not go too far---a real danger with ancient pipes---nothing worth a picture.

Then came the rim. The carbon was chipped off to check the state of the wood underneath, and sure enough, as already mentioned, it had been gently hammered round. Very evenly, though, so hardly any wood had to be removed to get back to flat, level, and sharp-edged. Slightly less than a millimeter. Not enough to affect the profile of the pipe, IMO.

For maximum authenticity, I used a pipe from my own rack that was the same size, shape, make, grain orientation, finish, and from the same production period to as a model for cutting the new rim. A pattern, if you prefer. Surprisingly, the profiles DO differ. Normal-wall-thickness Shells from this period are actually chamfered inward a few degrees. (re-sandblasting doesn't work, btw, for too many reasons to go into here. Just trust me when I say this sort of situation requires cutting by hand.)

Here are the two side by side:

.

And here is the result:

.

The stem was then de-greened with the usual parade of files and abrasives to get it back to black.

Here's where the pipe stands at the moment:

.

There was a catch to the de-greening, though. The oxidation was so thick---one of the ten worst cases I've seen---that AFTER it was removed, the stem was slightly smaller all over. Meaning (mostly) diameter. Meaning no longer level with the end of the shank when the two are put together: 8O

Oh No!!!! :twisted:

Will Ming the Merciless finally dispatch Buck and conquer the Universe? Or will he fight back and Truth, Justice, and the American Way will emerge victorious?

You'll have to tune in tomorrow to find out. :mrgreen:

- Status

- Not open for further replies.