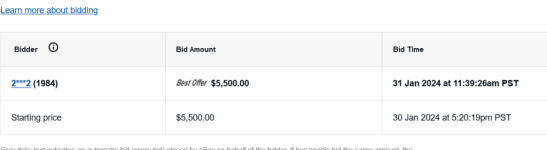

The easiest-to-see-it's-a fake "tell" with Dunhill pipes is the company

never went the pre-molded stem route.

Every stem ever made by them was from rod stock, no exceptions.

While a stem cut from rod can be made to

LOOK like it was originally molded (having a lack of material to shape is never a problem with rod), the opposite situation

IS a problem. A molded stem

DOES lack material unless one is chosen that is massively oversize to start with... and doing such selective reduction is more work & more difficult than using rod to start with.

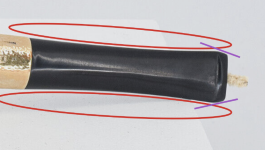

Where are the areas that lack material?

Unless it is a fishtail---meaning the button deliberately made wider than the shank---the sides of a Dunhill stem should be dead straight.

Also, the outside edges of the button on a Dunhill are never angled in, but rounded over.

View attachment 285264

View attachment 285261

Another tell is axial alignment.

Because clamping a pre-molded stem to cut a tenon is fussy and easily done a bit "off", while rod stock is essentially impossible to misalign, an axial screw-up scream "Molded!".

Dunhill would never allow such a pipe to pass QA.

View attachment 285266

Pics of the slots would reveal even more, as would an end view of the button shapes, but there are no pics from that angle.

I have no doubt they would look wrong, though, for both the same "not enough material" reason, and because anyone who was unaware of the problems described above would, by definition, lack the knowledge to make the button look right. (As well as the skill and special tools... copying by hand the traits of Dunhill's factory machines is tricky as hell).

I could go on, but breakfast is calling me, and I'm

hongry...