Harbor Freight Buffing Wheel

- Thread starter CrabbyPiper77

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Watch for Updates Twice a Week

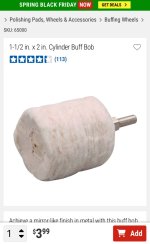

You may consider using a bench grinder and adaptors to mount wheels. 1725RPM Is a pretty good speed. What ever you use you'll need one wheel to apply the wax and another clean wheel to remove excess and polish. I use 6X1 buffs. I've never used a buff as pictured but it may work for you.

To apply carnauba you'll want a stiffer wheel to apply the wax, for bench grinders they are sometimes called "stitched" wheels. A fluffy wheel is used to polish after the wax application. Stitched wheels are also used if you need to buff ebonite stems. I use a Foredom bench grinder for my polishing needs, a drill press might work at a slow speed <1700 RPM.

I didn't realize you had to polish the wax. I polish the pipe and then wax it. That's all the instructing I found for buffing pipes online.

The beall buffing system is what I use. It comes in 4 inch or 8 inch I believe. I ordered it online for less that 100$Hey all! Has anyone used the below pictured buffing wheel from Harbor Freight? I want to use it in my drill press to polish my pipes with carnauba. Your input is greatly appreciated!

View attachment 302900

Chuck

Yes, you have to "polish" the wax. I really load up the wax wheel with carnuba, wax the pipe,then it looks milky and dull. Then with a clean soft wheel the the magic begins. Start off with junker pipes till you get the hang of it, there is a learning curve. Those wheels can grab a pipe right out of your hand in a fraction of a second, always with results you don't wantI didn't realize you had to polish the wax. I polish the pipe and then wax it. That's all the instructing I found for buffing pipes online.

This is with old pipes then? When I make a new pipe I always polish it, then wax. I guess I would polish the pipe, then wax, then polish the wax?Yes, you have to "polish" the wax. I really load up the wax wheel with carnuba, wax the pipe,then it looks milky and dull. Then with a clean soft wheel the the magic begins. Start off with junker pipes till you get the hang of it, there is a learning curve. Those wheels can grab a pipe right out of your hand in a fraction of a second, always with results you don't want

Yes, you do polish the pipe after your final sanding, at least that's the way I do it. I'm only speaking of my own experience. Sand the pipe to your standards, polish with polishing compounds, then apply the wax and polish or buff the wax as a final step. When I say "polish" I just mean buff the wax to a high gloss with a clean dry wheel. Dry meaning nothing applied to the wheel. Staining comes in to play at some point but every maker has his own techenique for that process. That's for new pipes. Old pipes can be polished with compounds to remove buildup that has accumulated over the years if you wish, again be careful,some compounds can be quite aggressive and very bad on nomenclature, then wax and polish. Or just wax and polish the estates without compounds. It all depends what your trying to accomplish.My buffer for wood and stems is 1725 RPM, for the silver, 3500 RPM. 1725 would work for metal but I think 3500 for wood and plastics may be a bit too fast. I use only unstitched cotton or muslin wheels for wood and plastic, occasionally stitched wheels for silver.This is with old pipes then? When I make a new pipe I always polish it, then wax. I guess I would polish the pipe, then wax, then polish the wax?

Last edited:

Mine is 3500 but my wheels are 4 inch. Interesting. I'll have to get another wheel. Thanks!

Yes, you do polish the pipe after your final sanding, at least that's the way I do it. I'm only speaking of my own experience. Sand the pipe to your standards, polish with polishing compounds, then apply the wax and polish or buff the wax as a final step. When I say "polish" I just mean buff the wax to a high gloss with a clean dry wheel. Dry meaning nothing applied to the wheel. Staining comes in to play at some point but every maker has his own techenique for that process. That's for new pipes. Old pipes can be polished with compounds to remove buildup that has accumulated over the years if you wish, again be careful,some compounds can be quite aggressive and very bad on nomenclature, then wax and polish. Or just wax and polish the estates without compounds. It all depends what your trying to accomplish.My buffer for wood and stems is 1725 RPM, for the silver, 3500 RPM. 1725 would work for metal but I think 3500 for wood and plastics may be a bit too fast.

If you're using 3500 RPM 4 inch wheels may be fine. You're getting into SFPM and you'll have to research that, or not. If it works for you and you've developed your own technique, go with that. Very beautiful art has been created with very few and simple tools in the right hands. Many tools are nice but clutter the work space, the real creativity is in the hands and mind.Mine is 3500 but my wheels are 4 inch. Interesting. I'll have to get another wheel. Thanks!

Caswell Electroplating for all my buffing suppliesIve had an easier time with unsewn wheels. They can be a little harder to find.

Polishing - Buffing Wheels - Caswell Inc

Jestco also very good

Just like an automotive paint job, polishing brings up the shine, wax then protects it.

I agree, I use mainly unstitched wheels. Stitched wheels are great, hold compound very well and have their applications, mainly for aggressive material removal. Some are even chemically treated to hold the compound longer. I use them only for aggressive first step metal polishing. Unstitched wheels are readily available in U.S.A. Polishing is a science of it's own. You could spend tens of thousands on all the different equipment that's been developed and have a whole building dedicated to only polishing. Then I think of guys like Paul Revere, that made incredibly beautiful silver tea sets....without electricityIve had an easier time with unsewn wheels. They can be a little harder to find.

Last edited:

And he was pretty damn good on a horse in the dark as well!I agree, I use mainly unstitched wheels. Stitched wheels are great, hold compound very well and have their applications, mainly for aggressive material removal. Some are even chemically treated to hold the compound longer. I use them only for aggressive first step metal polishing. Unstitched wheels are readily available in U.S.A. Polishing is a science of it's own. You could spend tens of thousands on all the different equipment that's been developed and have a whole building dedicated to only polishing. Then I think of guys like Paul Revere, that made incredibly beautiful silver tea sets....without electricitySimple techniques work!

Actually smaller is better, you can compensate for high RPM by using a smaller wheel. It reduces the SFPM (surface feet per minute) The larger the wheel the more SFPM you have the more aggressive it will be. The smaller the wheel the fewer SFPM the less aggressive it will be.Too small. Don’t get it. Get a bigger one.

If you run a VFD on your buffer and can control RPM without losing amperage/torque you can run large wheels. If you're running a fixed 1725-3300 RPM buffer with no VFD you need smaller wheels.

Turning, Drilling, Buffing, concentric grinding speeds are always calculated based on SFPM/Diameter and then controlled using RPM.

For instance a 3000rpm buffing motor with 8" wheels will run at 6283SFM but the same motor with 6" wheels will run at 4712SFM and 3" wheels will run at 2356SFM and those 1.5" wheels will run at 1178SFM. Wheel diameter is a great way to reduce aggressiveness for pipes without dumping a bunch of money into expensive motor controls.