he has been told in many different ways the answer to his question but there seems to be a comprehension problem because he has no experience at all

Kind of... my initial problem in the thread was having a lot of responses saying a pricier pipe is better, but no real info as to why.

So allow me to muddy the waters a little bit. With pipes there are no absolutes. One is always playing percentages. We buy a pipe with the hope that its maker produces a product of predictable quality. But briar being an organic material, there is always some variation.

As far as looking for a basic smoking implement, you can find excellent options in the $135 and lower range. Savinelli, Stanwell, and Peterson all make "entry" level pipes that do the job to the satisfaction of thousands of smokers. These makers also offer higher grades for people looking for more than basic.

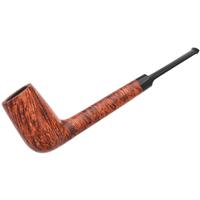

So what constitutes the difference? Materials and their processing. At the basic level you get a properly machine made pipe with good basic engineering using a middle grade briar that doesn't have spectacular grain, nor the best heat dispersion, nor the longest life expectancy, though with proper care you can get decades of pleasure from it. There will be sand pits and/or putty fills in the bowl's exterior, which do not affect the smoking quality, but which are not considered cosmetically desirable. The stems will be injection molded. To keep the cost down, handwork is kept to a minimum.

With more expensive pipes you get better materials and better processing. The briar comes from the plateau of the burl. The burl itself has been in the ground longer, developing better organic structure which translates, possibly, to better graining - tighter and more even grain - and better heat dispersion characteristics. The burl has been air dried for a longer period of time (which costs money) before it is cut into blocks from which pipes will be fashioned. The blocks are cut by hand by an experienced cutter (the most critical stage) who looks to maximize the quality of the block while cutting and tossing away the more questionable parts. The blocks are further aged, and/or treated with oil to remove remaining resins before being shaped. Storing materials for long periods of time, several years, is an expense.

When it's time to turn the blocks into pipes, there is more critical oversight with more expensive pipes. Makers who turn out only flawless smooth surfaced pipes toss out a lot of material in the process, or they "downstream" it to lower market brands. But choosing only the best material, or disposing of a less than perfect carving job also raises the cost and therefore the price. When you are buying from a high end maker, you're not just paying for that pipe, but you are also paying for the costs involved in making something of rare quality and that cost includes all of the throwaways - the pipes or wood that ultimately didn't meet the makers criteria for quality. All of that oversight costs money.

If the pipe is carved by hand, if the pipe has a hand carved stem made from very high grade material, if it has carefully wrought internal engineering and finishing, if the pipe is a one-of-a-kind artisan piece, if it is flawless, if it has superb grain, beautiful birdseye, etc, etc, all of that costs money to achieve and is reflected in the price of the pipe. And after all of that, the pipe may not smoke any better than a basic entry level pipe. But chances are that it will smoke very well and continue to do so for more than several lifetimes, with proper care.

If you are looking for absolutes, forget about it. There are too many steps and variables in the process for that to exist. But some manufacturers, such as Savinelli, Bjarne, Nording, and Stanwell have created very efficient production lines that allow them to produce a quality product for an affordable price.