James Foster, CST

Recently on the forums, an old post got resurrected about the differences between block and pressed meerschaum and the reminder was that pressed meerschaum is rarely used these days because it takes huge machines to use. I actually didn’t know this and thought it would be a good time to talk to some experts and pull out all the information about where the meerschaum industry is today. But before we talk about today how about a peek at the past. Did you know that we used to find meerschaum in the United States in New Mexico?

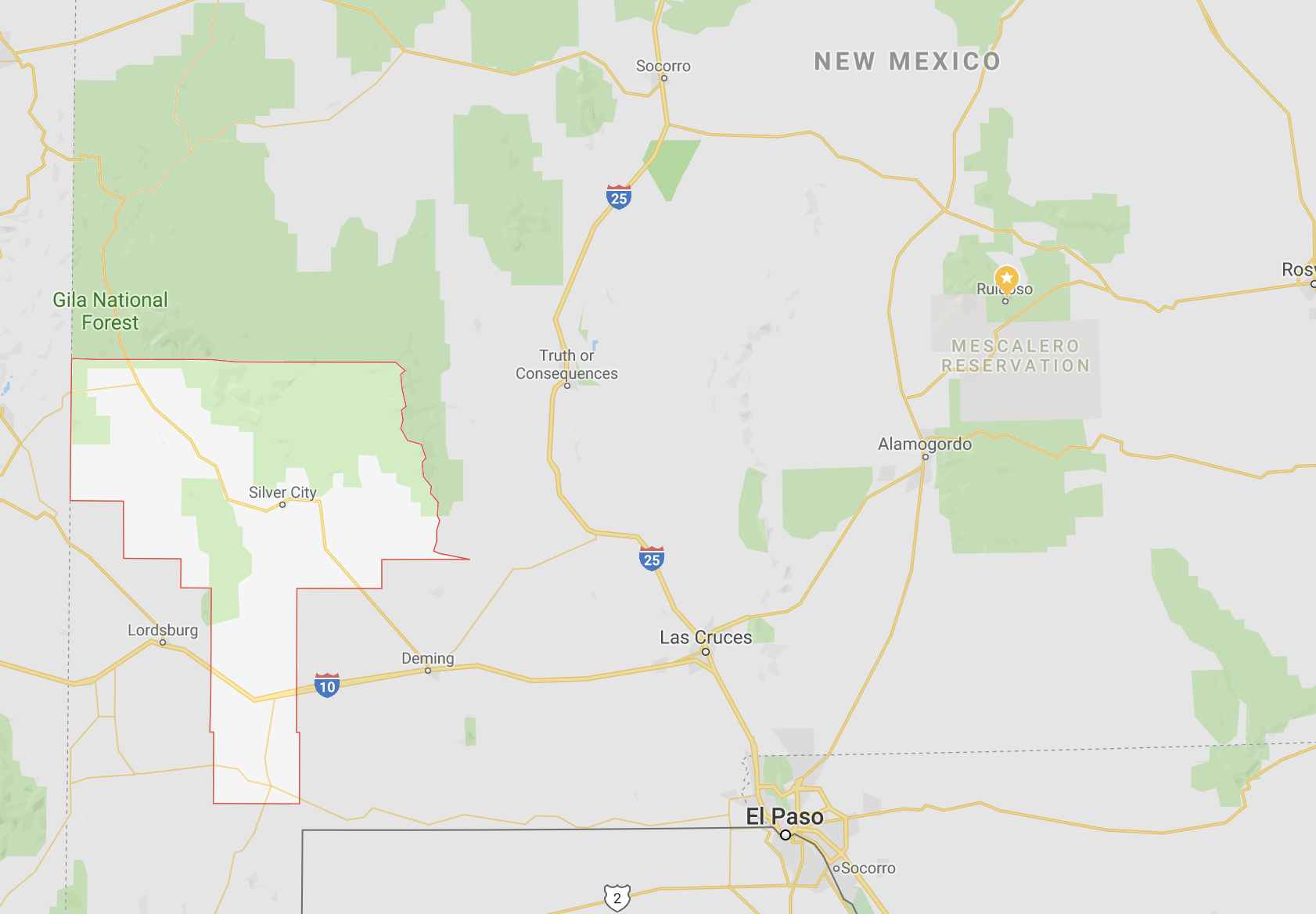

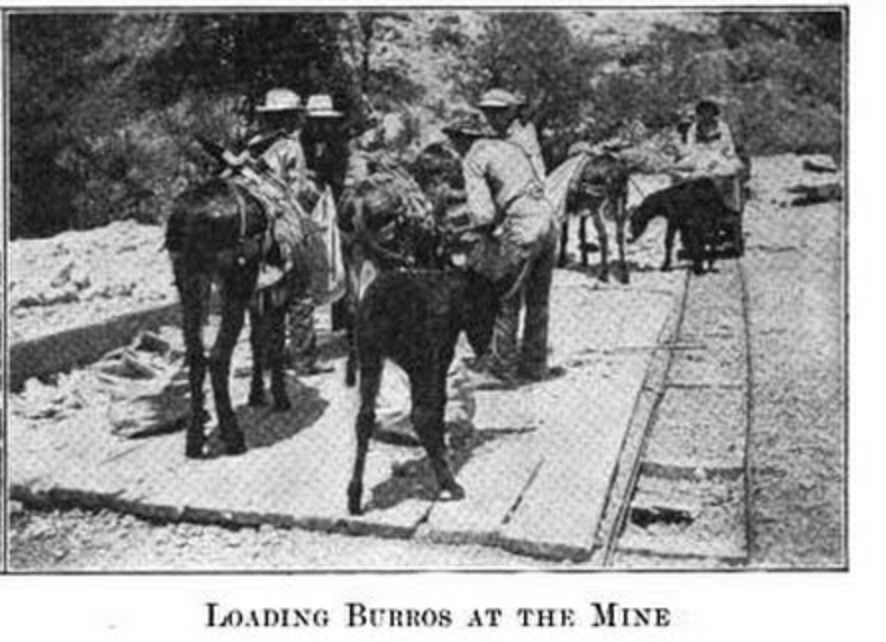

Let’s go back in time over a hundred years ago to 1907. Turkey, like today, controlled the worlds purest and best meerschaum which was used for pipes, and as a natural insulator for heat, cold, and electricity. We stumble across a hard to reach mine in the mountains near Silver City and Pinos Altos in South Western New Mexico. As an aside, 1907 was before we had automobiles everywhere – this was train country and the horse still reigned supreme when it came to local transportation. Not too far from the mine, only 26 years earlier, Billy, the Kid was shot dead.

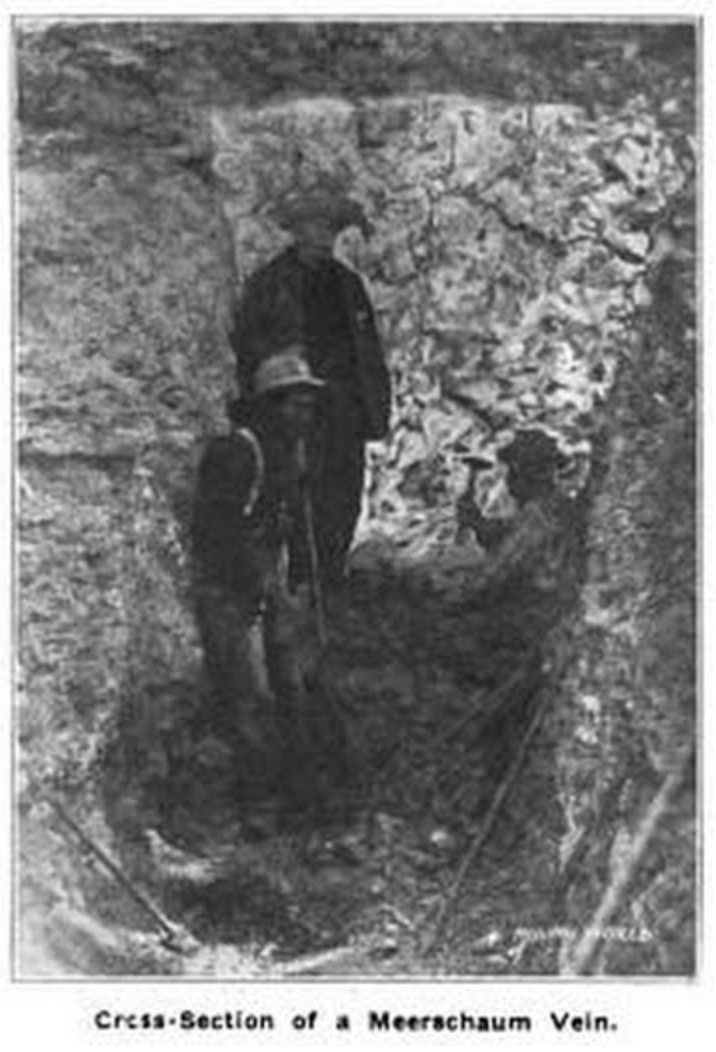

This discovery in New Mexico yielded a quality of meerschaum that was actually better than what was available in Turkey at the time. And, according to the book, – Mining and Engineering World they thought the monopoly of Turkish meerschaum was going to end with the find.

At the time only a few tons (a few tons ha!) had been shipped from the area because only a small trail existed from the mine to Pinos Altos and they were building a “wagon trail” which would have allowed them to bring up meerschaum at scale – commercially.

By 1910 or 1911 The Meerschaum company had gone into receivership and in 1912 reorganized as a new company called The American Meerschaum and Pipe Company in New York. In 1914 the company folded again because of not taking proper precautions in the mines. Even so by 1915, they had managed to pull out approximately 2 million pounds.

My research didn’t turn up much more – it appears that the mining operation shut down in 1915 after bankruptcy and during WWI and not much has been done since then – which leads me to believe we still have a significant supply of Meerschaum in the US that hasn’t been mined. The only other thing I found of interest was a funny article in 1908 in the New York Times.

“The recent discovery of huge deposits of meerschaum in New Mexico is of commercial importance, as supplies of this mineral in Asia Minor (Turkey), the Grecian Archipelago, Morocco, and elsewhere have been running low. Meerschaum is largely used in Germany in the manufacture of tobacco pipes, which are held therein even higher esteem than the large, decorated china pipes with betasseled stems. “

A bit further in the article

“The briar pipe is for smokers. It is made to be filled with tobacco and smoked. The meerschaum is an investment, an object of vertu, a subject of hourly perplexity. To treat one properly a high order of intelligence is required, together with complete freedom from defects of the artistic temperament, inexhaustible patience, and the philosopher’s mind.”

It’s funny to read the predictions about the future from over 100 years ago they turned out pretty poor, which goes with a similar trend today on our own predictions about how the world will unfold. But let’s not focus on the future, what about the present? What about the rumor I heard that we’re not getting any more pressed meerschaum? I pinged Meerqueen to find out more detail.

Block vs. pressed again – what’s the difference?

Every block meerschaum has many quality grades. We “MeerQueen” classified them in 6 grades. Below 4 (1-2-3) are bad quality. Lower quality 1-3 are heavier and they don’t smoke well as they do not absorb the nicotine well. Because of that, the meerschaum pipes of that lower grade do not color in a proper way. They may even crack like bad examples of pressed ones.

Grade 4-5 is good.

Grade 6 is the premium one (which is used only by 2-3 companies, and by very few artisans).

Pressed ones are generally heavier than grade 4-5-6 blocks.

It is difficult to know if you have a pressed one or grade 1-2-3 block as they have the same features. Today, mostly bad meerschaum pipes are made by grade 1-2-3 grades of block meerschaum.

In the past, we saw good examples of pressed ones and they were made of grade 5-6 block meerschaum pieces. But they were mainly produced for calabash bowl inserts and meerschaum linings and souvenirs.

So about this rumor about no longer getting pressed meerschaum?

Today there is no pressed meerschaum. Producing a GOOD QUALITY pressed meerschaum needs a good technology and a very big facility that you can not imagine.

What happened to all the pressed meerschaum manufacturing?

We had a modern and technological system for this but we closed these facilities.

Aside from pressed meer no longer being manufactured, everything else is good in the industry right?

Today most of the master carvers are retiring. Just a few talented young carvers are coming up. Unfortunately, Meerschaum art is about to die. A few years ago we were seeing many composition designs, dragon styles, and very detailed works. Nowadays, we mostly see classic shapes. In the past carvers spend 2-3 days for only one pipe. Now most of them are working on simple and easy models they crank out quickly.

Well, thanks for just ruining my sunny outlook for me. Ok, so how is the mining industry part of it going?

Meerschaum mining is one of the most difficult jobs in the world. It is mined from 200 to 300 feet under the ground surface, in irregular forms and sizes. Its fossilized remains of the sea-animals that lived millions of years ago. Mined with hand tools, and by men trained in this singular family tradition.

Eskisehir has the purest and best quality meerschaum blocks in the world. The best meerschaum pipes are made by using these blocks. The best quality of meerschaum in blocks are extracted nowhere in the world but only in Eskisehir /Turkey. Whereas the lower qualities do not absorb the nicotine as well as the others.

Villagers mine the meerschaum. There is no way you can know where the block meerschaum is situated underground. So they start to dig and go to one direction. If they can not find any they change the direction.

It is also difficult to work in those conditions under the ground. There is a death possibility if they make something wrong.

Any myths we need to dispell?

Some people say that you should not touch the meerschaum with your bare hands. This is not true. You can touch with your bare hands if the meerschaum waxing is done good, there is no need to worry.

Summarizing I’d say Turkey has some work to do to train up some new carvers and I need to invest in a mining operation and move to New Mexico. Thanks to Meerqueen for taking the time to answer a round of questions from me.

James Foster goes by the online handle of Pylorns in the forums, and he is the creator of an app for keeping track of your tobacco cellar inventory called The Pipe Tool, serves as the President of the Austin Pipe Club and is a Certified Tobacconist. James Foster goes by the online handle of Pylorns in the forums, and he is the creator of an app for keeping track of your tobacco cellar inventory called The Pipe Tool, serves as the President of the Austin Pipe Club and is a Certified Tobacconist. |

Fantastic research and article. I knew there were sepiolite deposits in the southwest but so little information of exploration or extraction is out there. Thank you for doing the footwork on this!

Thanks for a very informative article.

Thanks for the great article! I am surprised to read that Meerqueen still states that meerschaum is fossilized remains, as I though that was a myth proven false. Is that still being debated, or is the matter settled?

Fascinating post. Thank you James. Makes you think “what if”

I guess you’re now doing research into the exact location and ownership of the mine.

Yes pappymac.. next on the agenda!

Great article! I’d love to have an American mined meer….