Just received an Ashton (A Sovereign dated 1995) that I bought specifically because I can’t ever remember seeing an Ashton pipe with a horn stem before.

I am curious if anyone has any knowledge regarding horn stemmed Ashton pipes and in what capacity they were produced?

FWIW, it also has an orific-ish bit.

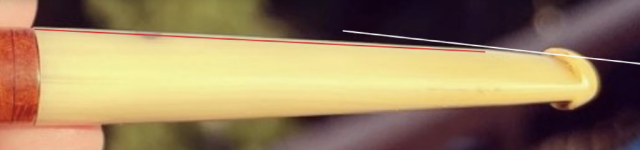

Additionally, this pipe also has a strange thin ring of color near the end of the shank that as of yet remains a bit of a mystery to me. Upon inspection of the mortise interior, it does not appear to be repair related.

The leading theory so far is that it is possibly coloring left behind from a since departed metal band of some sort, but this would be an awfully thin band, especially for Ashton, and it seems as though it is below the wax used to finish the pipe! Any and all theories on this would be appreciated as well! Thanks!

I am curious if anyone has any knowledge regarding horn stemmed Ashton pipes and in what capacity they were produced?

FWIW, it also has an orific-ish bit.

Additionally, this pipe also has a strange thin ring of color near the end of the shank that as of yet remains a bit of a mystery to me. Upon inspection of the mortise interior, it does not appear to be repair related.

The leading theory so far is that it is possibly coloring left behind from a since departed metal band of some sort, but this would be an awfully thin band, especially for Ashton, and it seems as though it is below the wax used to finish the pipe! Any and all theories on this would be appreciated as well! Thanks!

Last edited: