Nice find Al but I would certainly mount it to the bench rather than rely on its weight to hold it in place. That's how accidents happen :roll:

Regards,

Jay.

Regards,

Jay.

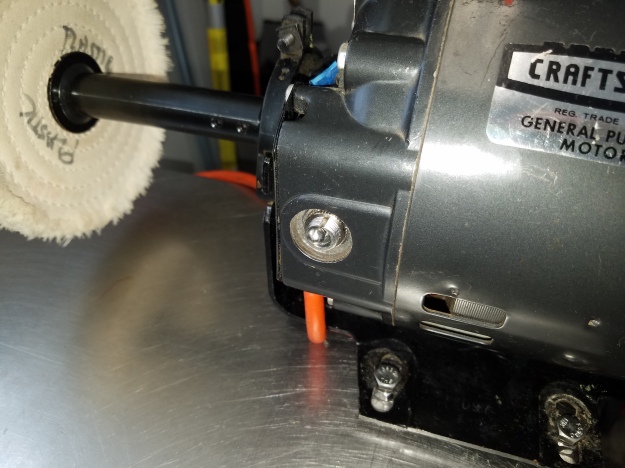

Well, perhaps. I don't exert much pressure using the rouges and plastic polish. With an double-power motor, I would expect less. The challenge is how to mount a double-arbor buffer. See the pix below, with the single-arbor, I have it mounted so the pad is off the edge of the table. I kind of work on the underside of the pad, as it spins away from me. That height is perfect. I could mount the dual-arbor in that spot, just at an angle, but that aims the object at the edge of the table.Nice find Al but I would certainly mount it to the bench rather than rely on its weight to hold it in place. That's how accidents happen [:roll:]

:

: