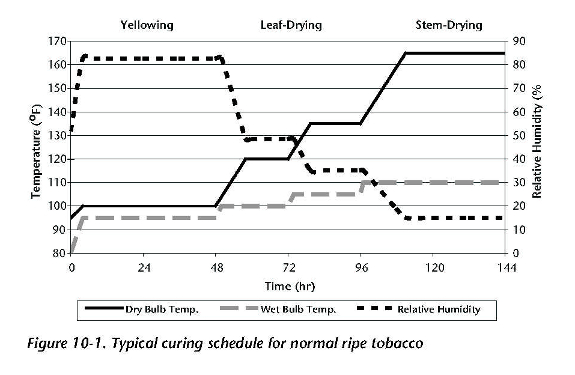

I am going to try to build an automatic flue curing chamber for next year's crop of home-grown Virginia Tobaccos. Growing the plants; I have one year of experience at. Building a box; I have many, many years experience doing. Getting a computer to take temperature and humidity readings and turning things on and off to hold those values to a schedule that changes over time? The thought of it gives me an ulcer.

Is there anyone in the community here who can/does/likes to mess around with this kind of thing? I'm checking here first because I'm hoping to exchange the product of my hobby for the product of yours.

Message me for details if you're interested.

Is there anyone in the community here who can/does/likes to mess around with this kind of thing? I'm checking here first because I'm hoping to exchange the product of my hobby for the product of yours.

Message me for details if you're interested.

.gif)