Torque, I do not see a link.

Yeah, the forum doesn't always post my sig, which is kind of odd. Direct link below.

Partial WDC Collection

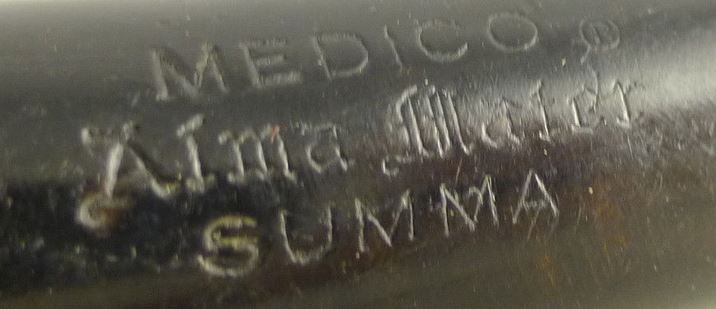

Below is the promised picture of both the Hesson and Hesson Guard systems.

Top: This is the Hesson Thread system that you would find in the Demuth manufactured BBBs and a lot of the WDCs from the 20s and 30s.

Bottom: The "Hesson Guard" system, and what most people think of when talking about a WDC Hesson style pipe. There are a ton of these that show up on ebay weekly. mlc has stated his belief that this system replaced the threaded inner tube while I suspect they were manufactured during the same time period, or at least had some overlap. I base this on some old court records that state the Wm. Demuth Co. took possession of the license for the Hesson patents from an Albert Freeman, somewhere around 1927. This tells me that WDC had access to both patents simultaneously and that one was not developed after the other, rendering the former obsolete. I could be very wrong in this regard but that's my best guess.

The Hesson Guard is a pretty unique system and rather innovative for it's time IMO. The inner tube, as you can see from the picture, has a rounded crimp on the end. This "nose" butts against the bowl drilling and the mortise extends all the way through the shank to the drilling. A cork plug was fashioned so that the OD of the plug was the same diameter as the mortise and had a hole through the middle that allowed for a press fit of the inner tube. The plug was also just a tiny bit longer than the "free space" in the mortise so that it compressed slightly when the metal tennon was fully inserted. The metal tennon was then glued into the shank and (assumedly) clamped until the adhesive set. The idea was that the cork would compress around the end of the inner tube (that butted to the bowl drilling) and seal the exit of the bowl so that any condensate could only go into the aluminum tube. Since the entire smoke stream was contained within the metal tube, it could be cleaned easily with a pipe cleaner without ever having to break the pipe down, since the cork seal never allowed any moisture into the shank. The patent (1855600) is a little hard to read, but once you get the jist of the system it's actually some pretty interesting stuff.