My first knife was a buck from Walmart when I was in cubscouts. I still have it somewhere. Most of the time I carry a CIVIVI Chevalier Flipper or a leatherman now.

The Perfect EDC Knife

- Thread starter Briar Lee

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Watch for Updates Twice a Week

I realize a flipper would probably be more practical but I'm an old fashioned guy so I just dig the look and feel of a folder.

The tiny Kershaw is my oldest. I got it from my sister for my 10th birthday which makes it about 45 years old now.

The Buck 110 is my newest. Only six months old. Pretty standard but upgraded with oak scales and s30v blade. Love everything about it except the concave blade grind (but that will get taken care of in time).

I'm not a hunter, so they meet daily needs pretty well. Which mostly includes cutting plug and rope tobaccos, and general everyday household and car duties (twine, boxes, those horrible molded plastic cases that manufacturers still insist on putting things in, and about a thousand other things).

The tiny Kershaw is my oldest. I got it from my sister for my 10th birthday which makes it about 45 years old now.

The Buck 110 is my newest. Only six months old. Pretty standard but upgraded with oak scales and s30v blade. Love everything about it except the concave blade grind (but that will get taken care of in time).

I'm not a hunter, so they meet daily needs pretty well. Which mostly includes cutting plug and rope tobaccos, and general everyday household and car duties (twine, boxes, those horrible molded plastic cases that manufacturers still insist on putting things in, and about a thousand other things).

My 1984 Case Sod Buster Jr. Is identical.My EDC is my dad’s (RIP) old Case XX Sodbuster. The plowman on the blade rubbed off a long time ago. I used to be able to faintly see it in the right light, but no more. I think he got this knife sometime in the 70s.

Case knives made since 1970 can be dated using this guide:

At $35 it’s still one of the least expensive models Case sells:

There are many excellent knives mentioned in this thread. My EDC is usually a Kershaw Leek, Kershaw Blur, Benchmade 610, Griptilian or mini Griptilian, or any one of probably 150 vintage knives. Generally I carry multiple knives, one for finer work and one for heavier cutting. I usually have one of the knives mentioned above and a vintage knife, perhaps a Cattaraugus, Schrade, Camillus, Western or Western States, or a vintage Sheffield knife or a vintage Solingen knife. I carry one of the older knives because I love the way carbon steel cuts and the ease with which sharpens. To me there's something satisfying about using a knife that was made 80 + years ago, living history in your pocket.

If I may be so bold, the information provided on the Buck 110, using 440C was correct until 1980. In 1981 Buck switch to 425 modified stainless steel. They use that steel until 1994 when they switch to 420 HC.

It is through the Heat Treating magic of Paul Bos that Buck is able to get such fantastic performance from what is generally regarded as a mediocre steel.

Paul Bos was the wizard who discovered how to heat treat stainless steel sword blades so that they were not so brittle that they would break. I had the pleasure of chatting with Paul at a Knife Show several years ago. Very interesting gentleman!

Buck used macassar ebony for the wood inlay in the handles of the 110 until 1991. In 1992 they switched to laminated Obeechee wood.

This information may be dated somewhat. I received it in 2010 from Joe Howser of Buck Knives. I am unaware of any further changes, but have not talked to Joe in several years.

Joe is the son-in-law of the late Chuck Buck.

If I may be so bold, the information provided on the Buck 110, using 440C was correct until 1980. In 1981 Buck switch to 425 modified stainless steel. They use that steel until 1994 when they switch to 420 HC.

It is through the Heat Treating magic of Paul Bos that Buck is able to get such fantastic performance from what is generally regarded as a mediocre steel.

Paul Bos was the wizard who discovered how to heat treat stainless steel sword blades so that they were not so brittle that they would break. I had the pleasure of chatting with Paul at a Knife Show several years ago. Very interesting gentleman!

Buck used macassar ebony for the wood inlay in the handles of the 110 until 1991. In 1992 they switched to laminated Obeechee wood.

This information may be dated somewhat. I received it in 2010 from Joe Howser of Buck Knives. I am unaware of any further changes, but have not talked to Joe in several years.

Joe is the son-in-law of the late Chuck Buck.

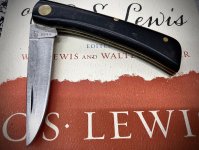

Here’s the first really good gas station counter barrel cheap stainless knife I ever saw, about 25 years old.

Notice the bolsters are milled stainless steel, not brass or nickel silver.

These were made for Boker in Asia, and are good, solid knives.

View attachment 250525View attachment 250526View attachment 250527View attachment 250528View attachment 250529

Notice the bolsters are milled stainless steel, not brass or nickel silver.

These were made for Boker in Asia, and are good, solid knives.

View attachment 250525View attachment 250526View attachment 250527View attachment 250528View attachment 250529

At $35 they must be made in China now?My 1984 Case Sod Buster Jr. Is identical.

Case knives made since 1970 can be dated using this guide:

At $35 it’s still one of the least expensive models Case sells:

Nope. Made in Bradford Pennsylvania.At $35 they must be made in China now?

I notice though, that a bone handle almost doubles the price of a Sodbuster.

Looking again at my Doom Blades (what a terrible, horrible name) flipper, this thing is an absolute masterpiece of product design.

What this knife is, basically, is an improved Buck 112 Light probably mostly made by robots.

The blade and the two stainless liners were likely all three made from the same ribbons of D2 steel. The scales were milled from a long sheet of G-10.

What you can’t see is how well it’s balanced and feels.

But look at the sorcery used to enable making unless thousands of these on an assembly line.

The last I read Chinese labor costs are $6 an hour now, and the wholesale cost of this perfect carry knife has to be half of $6, at most.

View attachment 250567View attachment 250568View attachment 250569View attachment 250570View attachment 250571View attachment 250576

What this knife is, basically, is an improved Buck 112 Light probably mostly made by robots.

The blade and the two stainless liners were likely all three made from the same ribbons of D2 steel. The scales were milled from a long sheet of G-10.

What you can’t see is how well it’s balanced and feels.

But look at the sorcery used to enable making unless thousands of these on an assembly line.

The last I read Chinese labor costs are $6 an hour now, and the wholesale cost of this perfect carry knife has to be half of $6, at most.

View attachment 250567View attachment 250568View attachment 250569View attachment 250570View attachment 250571View attachment 250576

Wow, still made in USA. Impressive!Nope. Made in Bradford Pennsylvania.

I notice though, that a bone handle almost doubles the price of a Sodbuster.

Wow, still made in USA. Impressive!

The Sod Buster is an extremely old Case pattern. It’s cheap because it has no bolsters, just a synthetic handle, brass liner, a pivot, two stud pins, and a blade.

Notice though, if Case uses bone instead of Delrin or Micarta it about doubles the retail price.

Cattle shin bones are a byproduct of beef processing, If there wasn’t a demand for knife scales they’d get ground up as bone meal or fertilizer. There’s likely not a penny’s worth of cow bone by the ton in a set of knife scales but the average cost of labor in wealthy nations like the USA, Germany, Japan, and other western nations means bone handles from nice, prosperous countries cost more than the blades.

That’s why my flea market special flipper is better. The supreme thermoplastic is G-10. And when I look at my G-10 scales closely there are no mold marks or tooling marks. Somewhere in China a laborer loaded a machine that made endless numbers of perfect scales, for nearly nothing each. And they fit, perfectly.

View attachment 250586

Remember the flea market owener wants the best seller he can buy for $3.50 and sell for $15 on his display counter.

My gas station special has a nice sized 3 1/2 inch D2 clip blade.

The secret is making a good, cheap handle for it, with a clip instead of a sheath.

I think Doom Blades found the perfect Chinese knife maker.

Here’s a brand thats extremely well built, titanium and cpms25vn steel.

View attachment 250588View attachment 250589

TOOR Merchant Not a flipper but a thumbstud and good enough for dress or jeans and for utility use or

Defense.

Again, that beautiful knife is nearly the same basic gadget as the Case Sodbuster, which was made back in Roman times. It’s a single blade folding knife.

What makes that one so special is a titanium scales.

Titanium is about $4,000 a ton and D2 (or 440 or 1095) costs about 90% less.

But we’re only using a couple or so ounces of $2 a pound metal for a blade, or for scales.

The reason my knife uses D2 for the blade is the much lower melting point.

D2 is a tool and die steel, one of the oldest. The factory likely buys it annealed and uses it for both the liners and the blade, then it’s heated in a purpose made furnace and air hardened. No human hands likely touch it before assembly,,,.if then.

D2 is not very tough, but tough enough for a disposable gas station knife.

And it holds an edge almost three times longer than carbon steel or 440.

And the circuit board G-10 costs maybe a few cents and it’s the best thermoplastic to keep exact dimensions.

The sharpness for me is the key.

CPM-S35VN is better than D2. It has more edge retention, corrosion resistance, ease of sharpening, and about the same toughness. The main difference between the two is that D2 rusts easier. If price isn’t an issue and you want high quality, go with S35VN. If you want something cheaper, go with D2.

D2 is great though and hard to beat

Between price and durability.

Small folders I don’t really care as I take care of my knives. Something larger like the Toor is purpose carried for skinning game or eliminating a threat.

CPM-S35VN is better than D2. It has more edge retention, corrosion resistance, ease of sharpening, and about the same toughness. The main difference between the two is that D2 rusts easier. If price isn’t an issue and you want high quality, go with S35VN. If you want something cheaper, go with D2.

D2 is great though and hard to beat

Between price and durability.

Small folders I don’t really care as I take care of my knives. Something larger like the Toor is purpose carried for skinning game or eliminating a threat.

The Sodbuster is a great, very basic knife that does what I need a knife to do. Pretty simple. My dad never had much money so I figured it must’ve been a cheap knife back in the day. The steel seems pretty subpar and it doesn’t take or hold an edge very well. My son’s Benchmade is a much better knife, as an example of contrast. I mostly carry my dad’s knife because it was his. I can still picture his crooked fingers fishing it out of the front pocket of his Wranglers. Some images remain for all of life.The Sod Buster is an extremely old Case pattern. It’s cheap because it has no bolsters, just a synthetic handle, brass liner, a pivot, two stud pins, and a blade.

Notice though, if Case uses bone instead of Delrin or Micarta it about doubles the retail price.

Cattle shin bones are a byproduct of beef processing, If there wasn’t a demand for knife scales they’d get ground up as bone meal or fertilizer. There’s likely not a penny’s worth of cow bone by the ton in a set of knife scales but the average cost of labor in wealthy nations like the USA, Germany, Japan, and other western nations means bone handles from nice, prosperous countries cost more than the blades.

That’s why my flea market special flipper is better. The supreme thermoplastic is G-10. And when I look at my G-10 scales closely there are no mold marks or tooling marks. Somewhere in China a laborer loaded a machine that made endless numbers of perfect scales, for nearly nothing each. And they fit, perfectly.

View attachment 250586

Remember the flea market owener wants the best seller he can buy for $3.50 and sell for $15 on his display counter.

My gas station special has a nice sized 3 1/2 inch D2 clip blade.

The secret is making a good, cheap handle for it, with a clip instead of a sheath.

I think Doom Blades found the perfect Chinese knife maker.

The Sodbuster is a great, very basic knife that does what I need a knife to do. Pretty simple. My dad never had much money so I figured it must’ve been a cheap knife back in the day. The steel seems pretty subpar and it doesn’t take or hold an edge very well. My son’s Benchmade is a much better knife, as an example of contrast. I mostly carry my dad’s knife because it was his. I can still picture his crooked fingers fishing it out of the front pocket of his Wranglers. Some images remain for all of life.

The odds are a loved one bought him that Case Sodbuster, and gave it to him as a gift.

Why Case still makes knives in Bradford and all the other American brands, even Buck, have some Asian production is Case has made and sold more expensive American knives for at least a hundred years than all the other brands combined.

Using stamped bolsters, Schrade sold more pocket knives at maybe half the price as a Case, and a two thirds the price of a Buck, forever until Schrade went bankrupt.

View attachment 250645

View attachment 250646

View attachment 250647

When I paid $25 for my Winterbottom (Delrin fake) Queen in 1974 a Case Folding Hunter cost more.

View attachment 250649

View attachment 250650

To this day carbon steel (1095) pocket knives are what all others compare to.

They’ll rust. But they take a wicked edge easily and hold it for more time than the average user needs to cut something.

Years ago maybe tape was all our fathers needed to cut, or open an envelope, and if they needed to cut card board they reached for a box cutter.

View attachment 250652

Our fathers used an Arkansas oil stone, one per lifetime, to whet their pocket knives.

View attachment 250653

Once you try a Diamond sharpener the Arkansas stones sleep in the tool box.

Last edited:

An extremely practical, working man's knife. Quite venerable.My EDC is my dad’s (RIP) old Case XX Sodbuster. The plowman on the blade rubbed off a long time ago. I used to be able to faintly see it in the right light, but no more. I think he got this knife sometime in the 70s.

I found on eBay the exact knife imported by another company for twice the price.

This one has a darkened blade.

View attachment 250660

I like the name a little better, but don’t like a darkened blade.

If they sold them with glow in the dark G-10 handles I’d like them best.

This one has a darkened blade.

View attachment 250660

I like the name a little better, but don’t like a darkened blade.

If they sold them with glow in the dark G-10 handles I’d like them best.

The odds are a loved one bought him that Case Sodbuster, and gave it to him as a gift.

Why Case still makes knives in Bradford and all the other American brands, even Buck, have some Asian production is Case has made and sold more expensive American knives for at least a hundred years than all the other brands combined.

Using stamped bolsters, Schrade sold more pocket knives at maybe half the price as a Case, and a two thirds the price of a Buck, forever until Schrade went bankrupt.

View attachment 250645

View attachment 250646

View attachment 250647

When I paid $25 for my Winterbottom (Delrin fake) Queen in 1974 a Case Folding Hunter cost more.

View attachment 250649

View attachment 250650

To this day carbon steel (1095) pocket knives are what all others compare to.

They’ll rust. But they take a wicked edge easily and hold it for more time than the average user needs to cut something.

Years ago maybe tape was all our fathers needed to cut, or open an envelope, and if they needed to cut card board they reached for a box cutter.

View attachment 250652

Our fathers used an Arkansas oil stone, one per lifetime, to whet their pocket knives.

View attachment 250653

Once you try a Diamond sharpener the Arkansas stones sleep in the tool box.

That exact knife in the top photo ... the Old Timer "stockman" (which I guess Schrade called a "middleman"?) ... was my first real knife. My dad bought it for me as a kid.

It's gone now. I don't know what happened to it. I remember having it at least through my teenage years.

I regret that.

Still have mine as well.That exact knife in the top photo ... the Old Timer "stockman" (which I guess Schrade called a "middleman"?) ... was my first real knife. My dad bought it for me as a kid.

It's gone now. I don't know what happened to it. I remember having it at least through my teenage years.

I regret that.