Good evening folks,

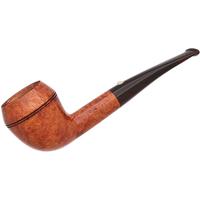

I would like to repair a cracked Peterson ferrule with solder and I'm running into problems. I have a scrap ferrule to play with and the solder paste is not running smoothly into the crack or surrounding divot, in fact it looks almost as if it being repelled by the crack regardless of the direction I heat or how much use. It is tending to bead and run off wherever the hell it likes, or part fill a divot and refuse to fill the other half (yes, I know, I sound like a lunatic). I am using low temp (281F) no clean soldering paste (contains flux) and a heat gun.

At first I thought I wasn't getting the ferrule up to temperature before the solder melted, but when I pre-heated the ferrule the results where the same. What I know about metallurgy you could write on a stamp (in a foot note), but I do know that some metals resist solder to a greater degree than others and require specific flux to counter this, but by my research I should be good to go with nickel.

Any ideas anyone? I would really like to nail this as the join is practically seamless. Is a butane iron the answer, or am I using the wrong solder?

Many thanks folks.

Geoff

I would like to repair a cracked Peterson ferrule with solder and I'm running into problems. I have a scrap ferrule to play with and the solder paste is not running smoothly into the crack or surrounding divot, in fact it looks almost as if it being repelled by the crack regardless of the direction I heat or how much use. It is tending to bead and run off wherever the hell it likes, or part fill a divot and refuse to fill the other half (yes, I know, I sound like a lunatic). I am using low temp (281F) no clean soldering paste (contains flux) and a heat gun.

At first I thought I wasn't getting the ferrule up to temperature before the solder melted, but when I pre-heated the ferrule the results where the same. What I know about metallurgy you could write on a stamp (in a foot note), but I do know that some metals resist solder to a greater degree than others and require specific flux to counter this, but by my research I should be good to go with nickel.

Any ideas anyone? I would really like to nail this as the join is practically seamless. Is a butane iron the answer, or am I using the wrong solder?

Many thanks folks.

Geoff

:

: