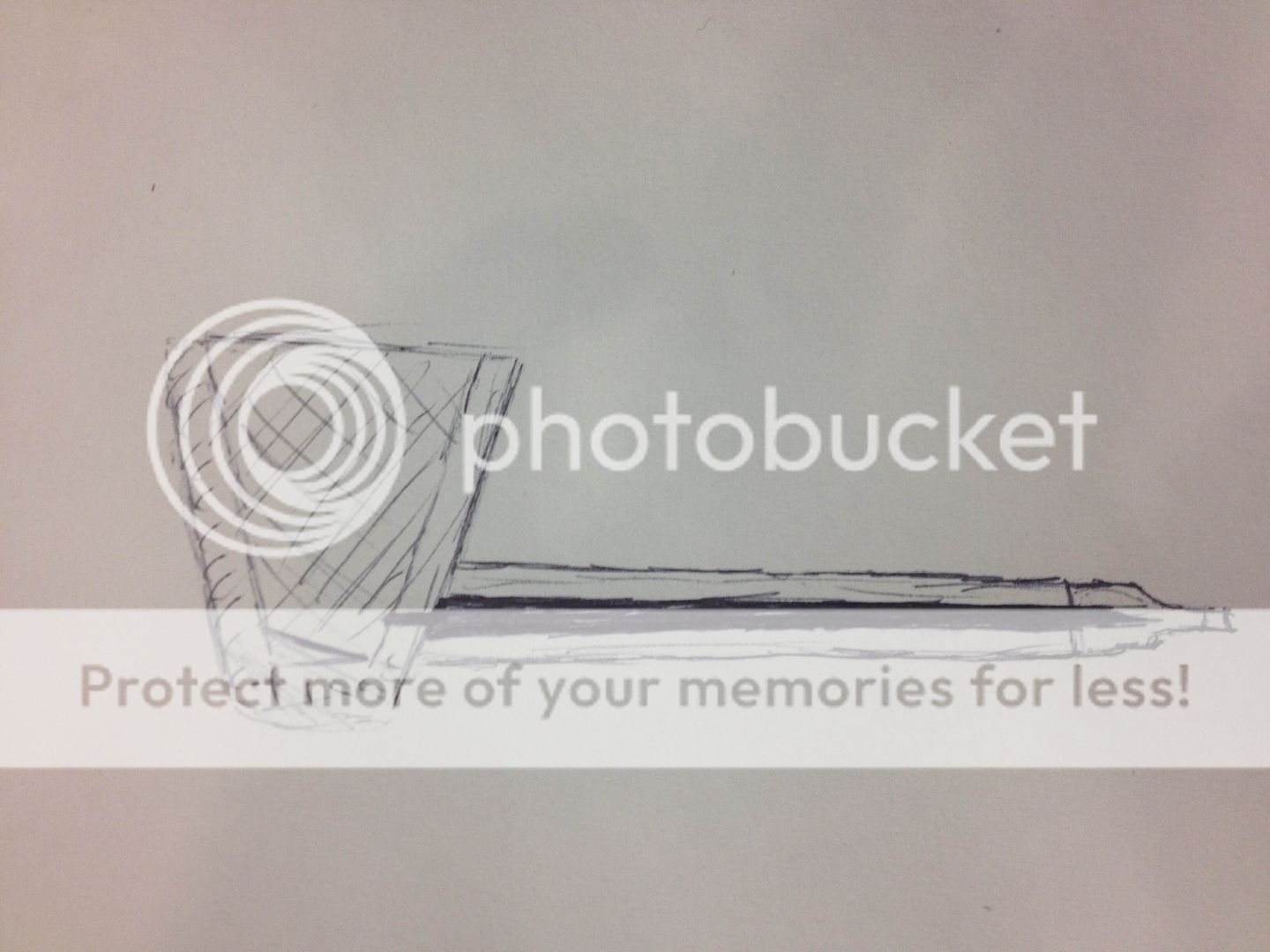

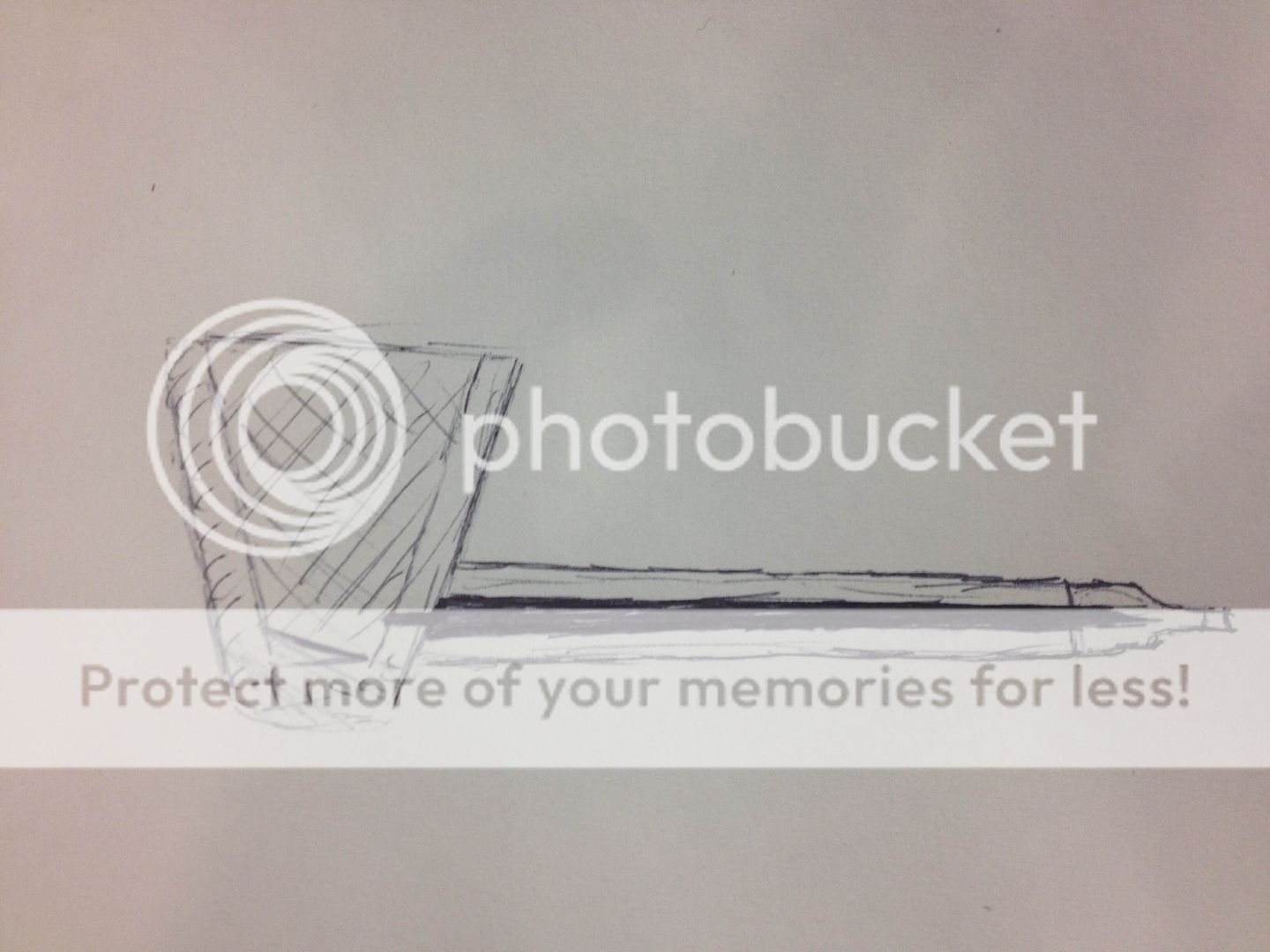

I'm working on expanding the hole in the shank of a modified cob pipe. The shank is fairly long and made of bamboo. I've been slowly working with a rat tail and chainsaw file to open up the shank, but I don't think my tools are long enough to make it to where the shank meets the original cob bowl. In other words, the hole drilled into the actual bowl is a bit smaller than the hole where it meets the shank. Hopefully my shoddy artwork does the situation justice.

My question is: assuming the airflow is good, is there any reason to continue working through the pipe so that I get the hole in the cob to the same width as the hole in the shank? Is this level of consistency really necessary? Or should I just leave well enough alone?

Thanks,

Dave

My question is: assuming the airflow is good, is there any reason to continue working through the pipe so that I get the hole in the cob to the same width as the hole in the shank? Is this level of consistency really necessary? Or should I just leave well enough alone?

Thanks,

Dave