Pre Carbonized Bowl?

- Thread starter madmike740

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Someone DOES actually pre-carbonize their bowls. I remember watching a video of them putting the pipe over a metal pipe with a flame coming from it in order to char the bowl. I just cant remember who! I do know I bought one or two of them once. Was it Blakemar, maybe? I stand firmly in the no bowl coating camp. Though, I will admit the taste problem 8s short lived.

Yeah, I recall that video, too. That's the only actual pre-carbonizing I've seen; all the rest is just a coating.

This.I've read that bowl-coatings are a means of keeping pipe buyers from burning out the bowls from over-smoking and starting burned patches. From my experience, this would be a rarity, but maybe it was a problem when the pipe industry was larger, and to volume pipe makers today.

Yes, but almost all burnout is partially user error. Or, rather, almost all burnout involves some user error. In my unscientific estimation, about 10% of burnout is because of very serious unforeseen and unseeable problems in the wood. 70% is a combination of minor faults in the wood (which are just a thing; it's briar, not steel) and minor user error (ranging from minor stupidity to the sort that, on a bad day, any of us might commit). The remaining 20% are the function of real user idiocy.

In reality, manufacturers take all, or almost all, of these back because that's the way it is. Short of someone saying, "well, I was smoking it while in a wind tunnel testing jet engines while using a trip torch lighter," it's just all a huge gray area. So, as an industry, we just make good on these.

Bowl coating, either as a matter of company or maker policy, or selectively, seriously cuts down on burnout rates in the first few smokes. Unlike, say, consumer electronics where most of the cost is in design and software, most of the cost in pipes are hard costs: factory labor, briar etc. Moving burnout rates from 2% to 0.5% might be the difference between a factory making money and not, and it certainly helps to hold pipe prices down a bit for factory pipes.

I have to say that I wince a bit when I hear people remove bowl coatings. I caution against it because it's not fair to go back to the manufacturer if you do have a problem if you've altered it before smoking it. Take out the bowl coating if you wish, but it does reasonably limit your recourse for replacement.

Sykes

Smoking while you’re layed up with the flu will FOR SURE alter your smoking experience,the flavor will be non existent.Just push on,and smoke the hell out the pipe when you get healthy again,and it will straighten out.Build up the cake,stick to one type of tobacco during breaking is my humble opinion.While I think it’s great fun to break in a pipe with an uncoated bowl,I have had no headaches with coated ones,either.I remember at one time,I purchased a new Savinelli with an uncoatrd chamber.Large pipe,large chamber.I had to smoke the DEVIL out of that pipe

Before it was broke in.

Before it was broke in.

I dislike bowl coatings and avoid them when possible. I like the flavor of a naked bowl while it is being broken in. The least offensive bowl coating was on a couple of Ferndowns I bought years ago. The worst bowl coatings were on the half dozen Formers I used to own.

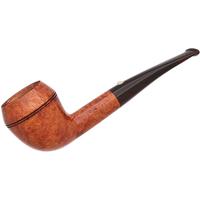

Breaking in a new Joe Hinkle Prince that has a bowl coating. (first bowl). I am smoking a Virginia Flake with Perique in this pipe.

I notice no odd flavors,only the true flavors of the tobacco.

I notice no odd flavors,only the true flavors of the tobacco.

I owned a 320 that had a carbonized bowl. The first 15-20 bowls in it were nasty tasting, because of the carbonized bowl. I was smoking Latakia blends that I was familiar with, so the bowl coating definitely tainted the smoke, but it eventually went away and became a go to pipe for me for a while.

The only other pipe I owned with a bowl coating was a Peterson, and I never noticed any tainted flavors with their bowl coating. I'm not sure what Savinelli uses for their bowl coating, but it definitely leaves a nasty taste for the first few smokes.

The only other pipe I owned with a bowl coating was a Peterson, and I never noticed any tainted flavors with their bowl coating. I'm not sure what Savinelli uses for their bowl coating, but it definitely leaves a nasty taste for the first few smokes.

my peterson came with the coating. it was actually sweet from first bowl. two of morgan bones came with coating, but i rubbed them out with alcohol. didn't taste anything.

- Status

- Not open for further replies.