My Vauen had two coats --- the top charcoal coat was fine. The grey paint coat underneath smelled like burning petroleum - had to sand down to briar and put in a pipemud coat to get rid of smell and flavor. Its a shame because they are some of the best smoking pipes made and real durable workhorses.

Peterson Short Army Coating and Break-in Questions

- Thread starter Sobrbiker

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Watch for Updates Twice a Week

Keeping Irish farming traditions alive !!!I've been going to town on my new short pipe since the moment I opened it from the mail package. In fact, I'm smoking it right now. No break in. No wipeout. Just straight to smoking. In fact, I've smoked it at least 30 times already and I haven't even cleaned it yet. YMMV. Sláinte!

View attachment 234827

I wonder if that was what was in my System 303 Heritage. It was a bare bowl with some little dark spots on it and would smoke along just fine and then I'd get hit with an unbelievably acrid taste. I thought maybe I was burning the briar. Fortunately, I discovered the recipe for the Peterson bowl coating on PPN and that really got things moving in the right direction.Be glad Peterson no longer dips their pipes. My first Peterson was a dip stained Killarney. It took me about 50 bowls to smoke that crap out of it!

Yep. Two brand new Petersons this month, both smoked great right out of the gate. Hard to argue with the results of this new Peterson bowl coating.Bingo. I love good bowl coatings.

What Peterson switched to is great. So, load & smoke.

Many naysayers have never actually tried the new coating, that's my experience.

Not a naysayer by any means, but I still remove the coating, takes a couple of minutes and I kind of like to see what's under. Comes off easily with paper towel/warm water - occasionally a little light sanding after, I don't sand it from the start because it just gums up the sandpaper and it is easy to wipe off with the paper towels to start. Usually don't sand unless there is some stain towards the top of the chamber I'd rather not see.

Quick update-

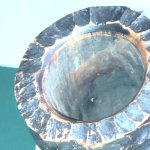

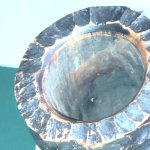

After cleaning, sanding, and a few smokes I cleaned it again and it’s definitely a decent pit in the briar.

Although I could live with it, it is a bit annoying being my first retail briar purchase.

I reached out to vendor (TP.com) saying I probably should’ve contacted them before smoking if it bothered me, but asked their input.

A return shipping label beat their email response this morning, and they said it looks like a defect and it’ll go back to Pete and a new one will be on the way to me.

The quality of service extended by them to a low budget customer such as myself over the last few months is what creates repeat business.

Its the little things that both thrill me and drive me nuts.

After cleaning, sanding, and a few smokes I cleaned it again and it’s definitely a decent pit in the briar.

Although I could live with it, it is a bit annoying being my first retail briar purchase.

I reached out to vendor (TP.com) saying I probably should’ve contacted them before smoking if it bothered me, but asked their input.

A return shipping label beat their email response this morning, and they said it looks like a defect and it’ll go back to Pete and a new one will be on the way to me.

The quality of service extended by them to a low budget customer such as myself over the last few months is what creates repeat business.

Its the little things that both thrill me and drive me nuts.

We certainly do!We have many vendors who supply first-rate customer service.

Now if we could only get them to all use labels on bulk bags that could be peeled off and stuck on a jar we’d really be poopin’ in tall cotton!

A

AroEnglish

Guest

Glad to hear about you getting good customer service from TP. I haven't had much experience with them regarding pipes as I like to see the pipe I’m buying but this is good news for us all.

Oh man that’s a great idea!We certainly do!

Now if we could only get them to all use labels on bulk bags that could be peeled off and stuck on a jar we’d really be poopin’ in tall cotton!

All of the bulk bags from SP come with a printed label that gets snipped off, dated, and taped to the mason jar.Now if we could only get them to all use labels on bulk bags that could be peeled off and stuck on a jar we’d really be poopin’ in tall cotton!

But wait!For me its like this. I've bought many Pete's with the black coating. I follow a 5 step process.

1. Remove pipe from big green box and green bag.

2. Look at pipe and say "Wow ! So much better than having that money in my wallet. I am very happy!"

3. Load the tobacco.

4. Light it.

5. Enjoy !

Aren’t you missing the step where you obsess about cake and breaking in and temperatures and ghosts and which tobaccos are appropriate for new pipes and bowl coatings and proper techniques and packing ratios and briars and pipes and vulcanite!?

If you don’t totally lose your shit, are you even smoking a pipe, bro?

I’ve never understood how prickly cotton plants against my bottom would be a positive thing! And not looking to be educated!!We certainly do!

Now if we could only get them to all use labels on bulk bags that could be peeled off and stuck on a jar we’d really be poopin’ in tall cotton!

Me either, and I’m somewhat of a word guy-but the colloquialism has a certain ring to it.I’ve never understood how prickly cotton plants against my bottom would be a positive thing! And not looking to be educated!!

I’m glad I did too, it’s already headed back.I'm glad you reached out about that pit. That is a burnout waiting to happen. TP is fantastic and will always take good care of you. I just saw this post and was about to comment that it is not an acceptable flaw.

It has amazed me in my brief time in the pipe community just how many incidents of people accepting flaws (bad drilling, pits, etc) folks seem accepting of, especially in much higher end pipes there are.

As many others have noted, Peterson no longer dip stains. Occasionally, you might see a bit of bleed at the top of the mortise, but nothing like when they dip stained. You might also see some dark areas in the mortise from the drilling process, which some pieces of wood are more prone to. I imagine that it would be most common in the system pipes because they simultaneously drill the mortise and moisture well and shape the shoulder on the lathe, so the bit is spinning inside the mortise for quite awhile.I just noticed this.

Before doing anything, is this flaw that is acceptable, or something bad enough that I should gripe to vendor?

Regarding the pit, it was of very little concern from a durability standpoint. Pits are almost always quite shallow and rarely more than a small fraction of the thickness of the wall.

One of the first steps in Peterson's manufacturing process is to sort the preshaped stummels by which finish they will receive. Each stummel is carefully examined, both dry and wet, for grain, color and flaws, like pits. The stummels with the most flaws or pits are graded for rustication. This doesn't mean that rusticated pipes are bad or are more likely to burn out. It's just a practical way to use that piece of briar and prevent it from going to waste, keeping the cost of all the pipes they sell to a minimum. Peterson's rustication process actually makes it one of the most expensive finishes for them to manufacture. IIRC, it takes an average of six minutes of to rusticate a pipe.

Since yours is a rusticated pipe, it's no surprise that there was a pit inside the tobacco chamber. Yes, this is one reason that manufacturers use bowl coatings --to hide inconsequential flaws. That, and even more importantly, to protect the bowl during the break-in period. The truth is, there could be a pit inside the chamber of a smooth Supreme-grade, too.

So, while your concern was understandable, in the future, don't let it worry you. I'm glad the good folks at Smokingpipes took care of your concern and that in the end you love your pipe. Happy smokes!

That is an excellent explanation and advice.As many others have noted, Peterson no longer dip stains. Occasionally, you might see a bit of bleed at the top of the mortise, but nothing like when they dip stained. You might also see some dark areas in the mortise from the drilling process, which some pieces of wood are more prone to. I imagine that it would be most common in the system pipes because they simultaneously drill the mortise and moisture well and shape the shoulder on the lathe, so the bit is spinning inside the mortise for quite awhile.

Regarding the pit, it was of very little concern from a durability standpoint. Pits are almost always quite shallow and rarely more than a small fraction of the thickness of the wall.

One of the first steps in Peterson's manufacturing process is to sort the preshaped stummels by which finish they will receive. Each stummel is carefully examined, both dry and wet, for grain, color and flaws, like pits. The stummels with the most flaws or pits are graded for rustication. This doesn't mean that rusticated pipes are bad or are more likely to burn out. It's just a practical way to use that piece of briar and prevent it from going to waste, keeping the cost of all the pipes they sell to a minimum. Peterson's rustication process actually makes it one of the most expensive finishes for them to manufacture. IIRC, it takes an average of six minutes of to rusticate a pipe.

View attachment 250089

Since yours is a rusticated pipe, it's no surprise that there was a pit inside the tobacco chamber. Yes, this is one reason that manufacturers use bowl coatings --to hide inconsequential flaws. That, and even more importantly, to protect the bowl during the break-in period. The truth is, there could be a pit inside the chamber of a smooth Supreme-grade, too.

So, while your concern was understandable, in the future, don't let it worry you. I'm glad the good folks at Smokingpipes took care of your concern and that in the end you love your pipe. Happy smokes!

Thank you so much for the response, very informative.As many others have noted, Peterson no longer dip stains. Occasionally, you might see a bit of bleed at the top of the mortise, but nothing like when they dip stained. You might also see some dark areas in the mortise from the drilling process, which some pieces of wood are more prone to. I imagine that it would be most common in the system pipes because they simultaneously drill the mortise and moisture well and shape the shoulder on the lathe, so the bit is spinning inside the mortise for quite awhile.

Regarding the pit, it was of very little concern from a durability standpoint. Pits are almost always quite shallow and rarely more than a small fraction of the thickness of the wall.

One of the first steps in Peterson's manufacturing process is to sort the preshaped stummels by which finish they will receive. Each stummel is carefully examined, both dry and wet, for grain, color and flaws, like pits. The stummels with the most flaws or pits are graded for rustication. This doesn't mean that rusticated pipes are bad or are more likely to burn out. It's just a practical way to use that piece of briar and prevent it from going to waste, keeping the cost of all the pipes they sell to a minimum. Peterson's rustication process actually makes it one of the most expensive finishes for them to manufacture. IIRC, it takes an average of six minutes of to rusticate a pipe.

View attachment 250089

Since yours is a rusticated pipe, it's no surprise that there was a pit inside the tobacco chamber. Yes, this is one reason that manufacturers use bowl coatings --to hide inconsequential flaws. That, and even more importantly, to protect the bowl during the break-in period. The truth is, there could be a pit inside the chamber of a smooth Supreme-grade, too.

So, while your concern was understandable, in the future, don't let it worry you. I'm glad the good folks at Smokingpipes took care of your concern and that in the end you love your pipe. Happy smokes!

It was the other guys (TobaccoPipes) but I’m sure SmokingPipes would have done the same.

I have learned that a lot of minor things such as my concern fall into the “if it bugs you now, it’ll bug you forever”, and while not a relatively large purchase it was the first non-estate briar I’ve bought, and I’m glad I got it taken care of. I know my expectations have been “educated”, such that if I’m buying a new pipe if significant expenditure I will either want to see it in hand or very well photographed before shelling out what meager sums I can afford to relegate to this of many hobbies.