One quick answer: a learning curve that generally started at 14.

The apprentice system survived in England at businesses large and small well into the 20th century. It was so prevalent in the briar pipe industry as to apparently be universal.

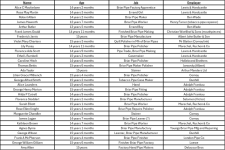

Here’s a sampling of now forgotten briar pipe workers who were 12 to 15 in the 1921 English census:

Note that this is far from complete; the search I performed was only intended to show that many boys and girls started working for pipe makers of all sizes as early as 12 years old. There are many instances I could cite of people who started in adolescence and worked in the pipe industry their entire lives. Unsurprisingly a number of the workers in this table had siblings and/or parents in the trade as well.

The point of course is that the level of skill consistently observed in pipes made several generations ago is at least in part a function of early mentor-based training embedded in a manufacturing culture of excellence.