I would not be able to say the quantities/yields from recent productions, although 30 years ago we were making approximately 45 pipes per day. Of these 45 finished pipes, we would have 'scrapped' 8 or so (and at the earliest stage possible) as we did not want to take one 'all the way through' production only to scrap it at the end. Say 20 or so would have been Tilsheads roughly 50% Natural and 50% dark, say 6 'S' grades 14 'P' grades, 3 'B' grades, 1 or 2 'G' grades. On another day, we may have 1 or 2 Bs, 1 G and an E or an X. Something like that anyway. There would be times when we were 'on a run'. The area where they were digging briar was far away from any footpaths, so the briar was not subjected to its branches being broken off for the inhabitants' firewood as they passed by. This 'branch-breaking' causes stress to the Xylem tissues/'veins' (as Pete explained earlier) and causes distortions, stress cracks in the burl etc. 'On a run' it has been known to yield 2 or 3 XX, 2 X, 4 Es, 5Gs, 5 Bs, 6 Ps and 2 S grades a day.

James Upshall Pipes - A Discussion

- Thread starter tarheel1

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Might I also add that 'on a run' i.e. when the briar is a treat to work with and the grain was to die for, the briar needed to be growing in an ideal place where the drainage was 'perfect', the nutrients from which it fed itself, rotting leaves and such like were all present in the optimum quantities, as well as the soil make-up AND free from 'disturbances' from passers-by (as mentioned above).

@neverbend, you are welcome sir, it is nothing compared to the information you are providing for pipe smokers like me.

Someone in this thread mentioned remembering a couple old unsmoked Upshalls at pipe stores he knew... it struck me that I knew of one too. I looked at it almost ten years ago now but bought a straight apple instead which I later, stupidly, sold.

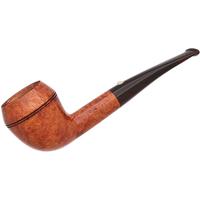

This was an old news stand / pipe shop that has since been sold, but the pipes are still there. While they've mostly been picked over, for some reason I had a feeling this old Upshall would still be there. It was. A P grade bent billiard. After minor haggling, it's now mine, and I'm pleased that it sat there waiting for me this long while. Now, what to break it in with...

This was an old news stand / pipe shop that has since been sold, but the pipes are still there. While they've mostly been picked over, for some reason I had a feeling this old Upshall would still be there. It was. A P grade bent billiard. After minor haggling, it's now mine, and I'm pleased that it sat there waiting for me this long while. Now, what to break it in with...

I still need to get an Upshall pipe, but really don't want to deal with the Ezratis. Wish I was around in the hay day of them. I was just a kid in the 80s and early 90s. I know I won't get the bulldog I desire, but maybe I can get a group 5 billiard with tapered stems.

There is a whole load of Upshall's on e-bay at the moment - Moti must be offloading.

Persevere Tarheel1. It took me a couple of years but I eventually got the Upshall I was after(a large 1/4 bent Dublin) I will shortly be in pursuit of a second Upshall pipe - it may take a while, but it will be mine. :D

Persevere Tarheel1. It took me a couple of years but I eventually got the Upshall I was after(a large 1/4 bent Dublin) I will shortly be in pursuit of a second Upshall pipe - it may take a while, but it will be mine. :D

Scanning this thread again - I'd love to hear more about the women of pipe making history. Pipes often feel like kind of a man's game, but it is refreshing to hear that women may have played a strong hand in the creation of some of the most premiere and classic British pipes.

"I'd love to hear more about the women of pipe making history. Pipes often feel like kind of a man's game, but it is refreshing to hear that women may have played a strong hand in the creation of some of the most premiere and classic British pipes".....

The staff at Charatan's was like a very large family. There were a couple of guys (Jeff was one) in the packing dept in the basement (until 1973),then the packing was done upstairs. The bowl turning room had copy-frazing machines to produce the series shapes (catalogue shapes) and two hand turning lathes. Sid was an old boy who re-set and repaired the machines and made any steel blades that were needed and re-sharpened blades etc.6 or 7 males worked in this dept. Then, in the sand-papering (and drilling) dept. it was women Joan, the most skilled sander and Prim who selected the bowls after they had been sanded. The boxes of bowls were stacked on shelves, Charatan bowls, Ben Wade, Mountbatten and Commadore. The Ben Wade and 'seconds' were then taken to the Ben Wade factory in Georgiana St. Camden Town and made into pipes there. The Charatans were then taken to the next dept (finishing) where 90% of the workers were women perhaps 10 in total. Maureen managed the finishing and was responible for grading all the Charatans into their respective qualities and she was the one who 'graded' all the straight grain Charatan freehands from 1968-1980. These 10 women did the pumicing, staining, hard mopping, stamping, bending mouthpieces, and final polishing. The Cafe on the top floor was run by Stan Haney's (hand-turner and craftsman) mother and I think his sister. So all in all there were more women than men! At James Upshall it was about 50% women. In my experience women are far better finishers than men except for Barry who was truly masterful at finishing. My father told me that Barry became such a good finisher because he loved to come and talk to the women in the finishing dept at Charatan's and gradually picked it up from them.

The staff at Charatan's was like a very large family. There were a couple of guys (Jeff was one) in the packing dept in the basement (until 1973),then the packing was done upstairs. The bowl turning room had copy-frazing machines to produce the series shapes (catalogue shapes) and two hand turning lathes. Sid was an old boy who re-set and repaired the machines and made any steel blades that were needed and re-sharpened blades etc.6 or 7 males worked in this dept. Then, in the sand-papering (and drilling) dept. it was women Joan, the most skilled sander and Prim who selected the bowls after they had been sanded. The boxes of bowls were stacked on shelves, Charatan bowls, Ben Wade, Mountbatten and Commadore. The Ben Wade and 'seconds' were then taken to the Ben Wade factory in Georgiana St. Camden Town and made into pipes there. The Charatans were then taken to the next dept (finishing) where 90% of the workers were women perhaps 10 in total. Maureen managed the finishing and was responible for grading all the Charatans into their respective qualities and she was the one who 'graded' all the straight grain Charatan freehands from 1968-1980. These 10 women did the pumicing, staining, hard mopping, stamping, bending mouthpieces, and final polishing. The Cafe on the top floor was run by Stan Haney's (hand-turner and craftsman) mother and I think his sister. So all in all there were more women than men! At James Upshall it was about 50% women. In my experience women are far better finishers than men except for Barry who was truly masterful at finishing. My father told me that Barry became such a good finisher because he loved to come and talk to the women in the finishing dept at Charatan's and gradually picked it up from them.

Hi Ken,

Did you know of one Alice Sturt at Charatan? I came into possession of a collection of Charatan pipes which included two letters, one signed by Reuben Charatan and the other indistinguishable, dating from 1958 / 59 - see another topic called Charatan collection. Some of the pipes are not stamped and others are not finished and I presume they were er "liberated" at some point. Any information on either the pipes or Alice would be useful as I am trying to piece together their history and what role Alice may have played in their production. The pipes are going off to John Marshall next week to see if he or Dennis can shed any light on them. Dennis in not in the best of health though.

As for Upshall's, fantastic pipes. I love the one I have which, thanks to your input on this forum, I have managed to date to pre 1983 as it is stamped and not engraved.

Keep up the good work as for us Upshall and Charatan anoraks, this is invaluable information.

Did you know of one Alice Sturt at Charatan? I came into possession of a collection of Charatan pipes which included two letters, one signed by Reuben Charatan and the other indistinguishable, dating from 1958 / 59 - see another topic called Charatan collection. Some of the pipes are not stamped and others are not finished and I presume they were er "liberated" at some point. Any information on either the pipes or Alice would be useful as I am trying to piece together their history and what role Alice may have played in their production. The pipes are going off to John Marshall next week to see if he or Dennis can shed any light on them. Dennis in not in the best of health though.

As for Upshall's, fantastic pipes. I love the one I have which, thanks to your input on this forum, I have managed to date to pre 1983 as it is stamped and not engraved.

Keep up the good work as for us Upshall and Charatan anoraks, this is invaluable information.

Wow. Thanks for the update Tarheel.Well I was told Moty passed 3 weeks ago and Barry retired. I am guessing that is the end of this fine brand as well.

RIP

I just discovered this thread, and think it is one of the most interesting threads that I have read.

Mike

This was the thread that got me back into the 'pipe making' world. It also brought back so many memories, emotions and friends. Some of these people I have not been in touch with for nearly 30 years and include Pete and Debbie Siegel, Les Wood from Ferndown Pipes and L&J Silverware and Barry Jones. I have since spent many hours with Barry, in person and on the 'phone and absorbing some amazing info from the late 50s working with Reuben Charatan. I feel that a book may be on its way and possibly more!

I wish I had back every single Upshall I ever owned back. $125 for a P was more than a bargain, it was grand larceny. The much complained of bits were never that big a problem for me, though I did have one moose of a Tilshead Canadian that had the worst bit ever put on a pipe.

In the mid-90's, neverbend was gracious enough to let me acquire two large lovats, at least one of which was a G, I believe, that had replacement Lucite stems hand cut by Rich Lewis. Truly a revelation as to how good a Lucite mouthpiece could be.

I recently acquired a large Tilshead Lovat from a well known collector who acquired it new in the very early years. It had not been smoked, or cleaned, in many years. It has one tiny, tiny fill on the right side of the bowl about half way up. I just got it back a few weeks ago from Mary Ann Keller and it is an extraordinary smoke. I am jaded, and I very rarely say one well made, clean, broken in pipe smokes better than another, but this time around, that pipe will be a problem for my executor! I am tempted to send it to Rich Lewis for a hand cut Lucite bit, but I might not live long enough to get it back

In the mid-90's, neverbend was gracious enough to let me acquire two large lovats, at least one of which was a G, I believe, that had replacement Lucite stems hand cut by Rich Lewis. Truly a revelation as to how good a Lucite mouthpiece could be.

I recently acquired a large Tilshead Lovat from a well known collector who acquired it new in the very early years. It had not been smoked, or cleaned, in many years. It has one tiny, tiny fill on the right side of the bowl about half way up. I just got it back a few weeks ago from Mary Ann Keller and it is an extraordinary smoke. I am jaded, and I very rarely say one well made, clean, broken in pipe smokes better than another, but this time around, that pipe will be a problem for my executor! I am tempted to send it to Rich Lewis for a hand cut Lucite bit, but I might not live long enough to get it back

Part of that post seems to have been lost. Here is the rest.

Ken, thank you so very much for participating in this thread. To all, neverbend has always been very generous in sharing his Marble Arch experiences. We need to get him started on Ser Jacopo!

Ken, thank you so very much for participating in this thread. To all, neverbend has always been very generous in sharing his Marble Arch experiences. We need to get him started on Ser Jacopo!

When I first started smoking a pipe I had the opportunity to buy some Upshall pipes from a lady who acquired them when her father passed on, she wanted $100 for all 5 pipes, I passed because I didn't know anything about the maker and thought they were cheapo pipes and I wasn't gona spend that kinda money for "used" pipes, Ive been kicking myself over that for 17 years