Hand Crafted Pipe Rack

- Thread starter bullbriar

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Wonderful piece, bullbriar. I love the look and the craftsmanship. If I tried something like that, I'd lose all my fingers in the process. You are talented, sir.

I have to tell you that of all the years I spent in public school, my favorite course was shop, where we also learned mechanical drawing, the subject I liked the most. I have forgotten most of my teachers' names, but still remember the precise and articulate gentleman who taught that course. So, since I can't thank him, I am thanking you.

Rickpal,

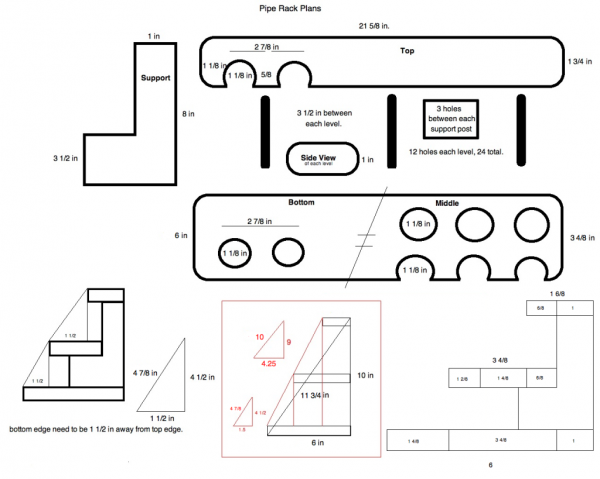

Since I wanted a roundover on a shallow (3/16) hole, I had to resaw 3/16" off the top of each board, through-drill with a 1 1/8" forstner bit, router the hole's edge with a roundover, then glue it back to the original piece. You can see that on the edge of the middle and bottom shelves. It was a nice demo for the kiddos.

If you don't need a roundover, just drill the board with the forstner bit. It will make a flat-bottomed hole, with a tiny countersink in the middle which can be hidden by the felt (or leather?).

Since I wanted a roundover on a shallow (3/16) hole, I had to resaw 3/16" off the top of each board, through-drill with a 1 1/8" forstner bit, router the hole's edge with a roundover, then glue it back to the original piece. You can see that on the edge of the middle and bottom shelves. It was a nice demo for the kiddos.

If you don't need a roundover, just drill the board with the forstner bit. It will make a flat-bottomed hole, with a tiny countersink in the middle which can be hidden by the felt (or leather?).

Ditto me on thanks for my two years of mechanical drawing classes I had. They are paying off for me right now in work projects. Never had a wood shop class, although that became a big and satisfying hobby much later in life. (My wood shop equipment has sat in storage for 11-12 years now.) Maybe when I actually resume married life one of these days, it'll be a good way to stay outta my wife's hair while she's busy dusting the teacups and doing her painting and 3-D landscape design. :rofl:

Comment about method use for the "bowl depressions." Could a plunge router implementation have made it easier, or would it be risky with the oak's open grain? Curious about that.

Comment about method use for the "bowl depressions." Could a plunge router implementation have made it easier, or would it be risky with the oak's open grain? Curious about that.

Boudreaux,

Yes a plunge router could have been used if you had the right bit (with the roundover)the right bushing, and then you would have to make a template for the holes to ride the bushing on. Just seemed easier the other way! I have a CNC router that I received through a grant that might be the best thing yet for the bowl depressions. I'll have to see once its set up!

Yes a plunge router could have been used if you had the right bit (with the roundover)the right bushing, and then you would have to make a template for the holes to ride the bushing on. Just seemed easier the other way! I have a CNC router that I received through a grant that might be the best thing yet for the bowl depressions. I'll have to see once its set up!

What a great looking pipe rack bullbriar! It looks ten times better than some of the really expensive racks available online. Never would have thought to include felt bottoms, great job! (Noticed that you have the same pull apart bolt lighter as me  )

)

Perfect!! That makes sense now! Now to get the needed materials..... Tomorrow will be a busy day!Rickpal,

Since I wanted a roundover on a shallow (3/16) hole, I had to resaw 3/16" off the top of each board, through-drill with a 1 1/8" forstner bit, router the hole's edge with a roundover, then glue it back to the original piece. You can see that on the edge of the middle and bottom shelves. It was a nice demo for the kiddos.

If you don't need a roundover, just drill the board with the forstner bit. It will make a flat-bottomed hole, with a tiny countersink in the middle which can be hidden by the felt (or leather?).

- Status

- Not open for further replies.