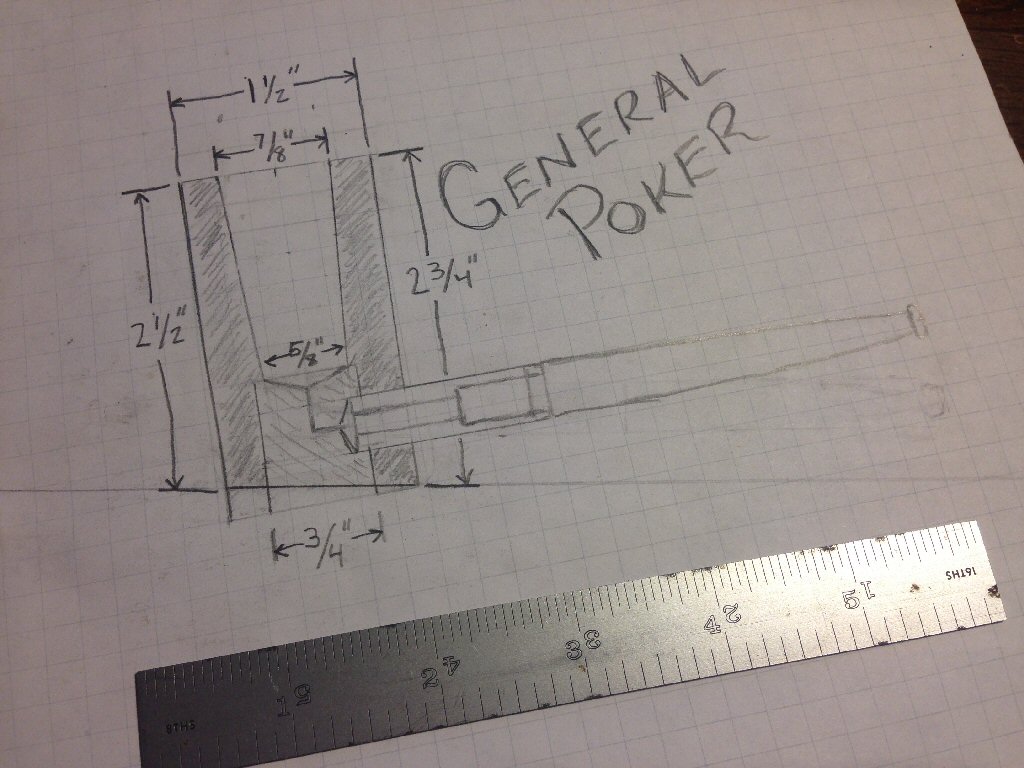

General Poker (Air passage)

- Thread starter cbates55

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Watch for Updates Twice a Week

- Status

- Not open for further replies.

Yeh, the bend is going to give you fits trying to pass a pipecleaner. Is it designed to have a plug in the bottom of the bowl?

If you can remove the angle and let it transition smoothly, which I can hardly imagine being easily doable, it might be fine.

Otherwise, that 90 degree angle looks like a pain to deal with, and the airway seems to be tight as well, in that area.

Otherwise, that 90 degree angle looks like a pain to deal with, and the airway seems to be tight as well, in that area.

A draft hole going straight down through the bottom of the bowl has to have an open sump area, like a classic calabash design or a Falcon-type design. Otherwise, the 90-degree bend will become the moisture-collection point as well as the choke point for loose tobacco bits.

- Status

- Not open for further replies.