First Time Making a Stem.

- Thread starter jewman22

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Watch for Updates Twice a Week

Yes. But if you’re uninitiated you can burn through a lot of material. A lot of people aren’t aware of speeds and feeds, when they first set out to start making stems out of acrylic.Again, it goes to knowledge of the material and ones tools.

Nor fine rifles from a plank of wood and metal. That is the why of material and proper tool knowledge.Yes. But if you’re uninitiated you can burn through a lot of material. A lot of people aren’t aware of speeds and feeds, when they first set out to start making stems out of acrylic.

Most of my stocks are worked primarily with rasps and files, machines only when they are the better for the purpose.

Speeds and feeds are quite important when chambering a barrel to .0001 to .0003 inch.

While I'm not a pipe maker, rather a gunsmith, skillsets cross.

Yeah, just learned that the hard way, broke my last tapered aircraft drill bit, ended up step drilling.Drilling acrylic can be problematic too...

It's unfortunate that the particular acrylic I used is transparent.

I'l post a pic in a minute. I'm going to try again, as I still have enough for 2 more attempts. But need to order some more drill bits before I do.

Too much heat is created when the feed or speed is high. It causes the plastic material to melt, grabbing the drill, or the drill binds from too much feed.Yeah, just learned that the hard way, broke my last tapered aircraft drill bit, ended up step drilling.

It's unfortunate that the particular acrylic I used is transparent.

I'l post a pic in a minute. I'm going to try again, as I still have enough for 2 more attempts. But need to order some more drill bits before I do.

Yup figured too much feed based on how it grabbed.Too much heat is created when the feed or speed is high. It causes the plastic material to melt, grabbing the drill, or the drill binds from too much feed.

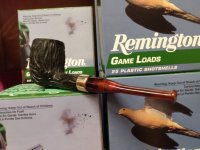

Here is my pathetic attempt at Acrylic.

Still got a bit of messing about to do with the button, but this material is such a pain in the ass compared to vulcanite, I had little to no issue with that stuff.

There was a small crack in the shank, had to make a band for it. Buddy gave me a few crappy pipes that belonged to an old friend of his, this was the first one.

Still got a bit of messing about to do with the button, but this material is such a pain in the ass compared to vulcanite, I had little to no issue with that stuff.

There was a small crack in the shank, had to make a band for it. Buddy gave me a few crappy pipes that belonged to an old friend of his, this was the first one.

Looks like a good start.?Here is my pathetic attempt at Acrylic.

View attachment 107670

View attachment 107672

Still got a bit of messing about to do with the button, but this material is such a pain in the ass compared to vulcanite, I had little to no issue with that stuff.

There was a small crack in the shank, had to make a band for it. Buddy gave me a few crappy pipes that belonged to an old friend of his, this was the first one.

Thanks, I still have a long way to go, but I'l get there eventually.Looks like a good start.?

Practice makes perfect.?Thanks, I still have a long way to go, but I'l get there eventually.

Nor fine rifles from a plank of wood and metal. That is the why of material and proper tool knowledge.

Most of my stocks are worked primarily with rasps and files, machines only when they are the better for the purpose.

Speeds and feeds are quite important when chambering a barrel to .0001 to .0003 inch.

While I'm not a pipe maker, rather a gunsmith, skillsets cross.'

That's why they make finish chamber reamers with pilots...

@Chasing Embers

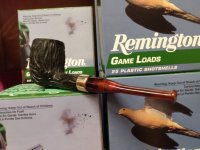

This is a type work I do.

If the off topic lic is improper, it can be removed.

All wood work was do with rasps, files, and scraper before finishing.

This is a type work I do.

If the off topic lic is improper, it can be removed.

All wood work was do with rasps, files, and scraper before finishing.