There seems to be some confusion about the different methods of bowl repair, so let me try shed some light on this.

There are two primary methods of interior chamber repair and they accomplish different things. They are for the most part not interchangeable.

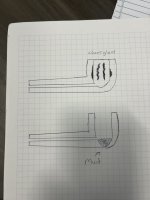

Pipe Mud- a thick mixture of ash and water to create mortar. It's that simple, it's just mortar. It's most frequently done by mixing cigar ash and water to create a paste. Cigar ash is used because it's finer and requires no sifting out of dottle, pipe ash can be used but you would need seperate the dottle from the ash. This is used for repairs where bulk material needs to be added back, like a chamber thats been reamed down past the draught hole to far or just drilled that way to begin with. Just like brick mortar it shrinks as it dries that is why it makes a poor material to use for burnout/char repair. It can also contract and expand under heat, if packed into char it can force the cracks apart causing more damage.

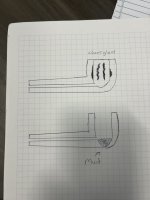

Bowl coat (waterglass)- A mixture of sodium silicate and carbon. Sodium silicate is a high temperature adhesive, in this way its used as a carrier and fixer for carbon. This is typically used to repair interior burnout/char. With the sodium silicate and carbon mixed into a thin paste its forced into the char creating a "fireproof" carbon layer preventing any further burnout. This mixture is fairly thin and cannot be used to build up missing material only to fill small voids, stabilize, and fireproof.

Bowl coat can and should be used over the top of pipe mud when it's used fill large voids and bowl heels. But pipe mud should not be used to repair char. If a chamber is simply charred, just bowl coat it. If a chamber is over drilled/reamed mud the heel and bowl coat over the top of it.

For ultra heavy repairs a hybrid mixture of the two can be made but it tends to not be as stable and has tendency to flake and crack. It's better to make them independently from each other.

I'm not claiming these are the ONLY methods, but they are the most tried and true. Other folks may use other concoctions and have some success but these two have been used this way for years and are proven to work. My main goal here is to define the difference between the two and explain their uses. Not to claim they are the only viable methods. So before you start chiming in with other recipes and wonder products, please be aware that I'm not here to make any claim that your methods don't work and shouldn't be used, just to lay out the basic ones.

There are two primary methods of interior chamber repair and they accomplish different things. They are for the most part not interchangeable.

Pipe Mud- a thick mixture of ash and water to create mortar. It's that simple, it's just mortar. It's most frequently done by mixing cigar ash and water to create a paste. Cigar ash is used because it's finer and requires no sifting out of dottle, pipe ash can be used but you would need seperate the dottle from the ash. This is used for repairs where bulk material needs to be added back, like a chamber thats been reamed down past the draught hole to far or just drilled that way to begin with. Just like brick mortar it shrinks as it dries that is why it makes a poor material to use for burnout/char repair. It can also contract and expand under heat, if packed into char it can force the cracks apart causing more damage.

Bowl coat (waterglass)- A mixture of sodium silicate and carbon. Sodium silicate is a high temperature adhesive, in this way its used as a carrier and fixer for carbon. This is typically used to repair interior burnout/char. With the sodium silicate and carbon mixed into a thin paste its forced into the char creating a "fireproof" carbon layer preventing any further burnout. This mixture is fairly thin and cannot be used to build up missing material only to fill small voids, stabilize, and fireproof.

Bowl coat can and should be used over the top of pipe mud when it's used fill large voids and bowl heels. But pipe mud should not be used to repair char. If a chamber is simply charred, just bowl coat it. If a chamber is over drilled/reamed mud the heel and bowl coat over the top of it.

For ultra heavy repairs a hybrid mixture of the two can be made but it tends to not be as stable and has tendency to flake and crack. It's better to make them independently from each other.

I'm not claiming these are the ONLY methods, but they are the most tried and true. Other folks may use other concoctions and have some success but these two have been used this way for years and are proven to work. My main goal here is to define the difference between the two and explain their uses. Not to claim they are the only viable methods. So before you start chiming in with other recipes and wonder products, please be aware that I'm not here to make any claim that your methods don't work and shouldn't be used, just to lay out the basic ones.

Last edited: