Thank you all, I appreciate the comments.

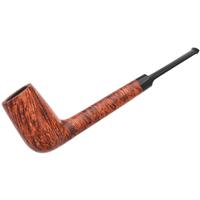

jmatt - I'm pretty sure a Canadian is a bit longer but the main distinction is that a Canadian would have an oval shank but I think it could well be called a Canadian or a Lovat and since I do not have a Lovat maybe when I wish I had one I will smoke this and call it my Lovat.

ejames, this is fast becoming my favorite shape as well.

jp, very good eye. I was wondering if anyone would comment on that. My usual stem finishing process is to use micro-mesh out to 12,000 grit. It's tedious and slow but I know it works. I have been reading and learning mostly from the pipemakers.com forum and so I tried something different. By the way, that forum is +1 for cut-to-the-chase honest and at times painful critique but it is all part of the learning curve. Anyway I decided to buff everything as one on the wheels moving progressively up the grits. At the green diamond wheel I managed to scuff the stem at the shank junction. I tried fixing it by backing down to 2400 on the mess and then going to carnauba wax but by this time I was worried about the actual interface and decided to leave it and it will go into my learning curve drawer. Hopefully some of the other builders on here will shed some light on their stem/shank finishing process.

Mike to answer your question, yes, I destroyed a poker that I was very pleased with until I decided to cut an angle on the bottom of the bowl (which would technically make it a cherrywood) and could not get the balance right and ended up cutting through the tobacco chamber so that would make five briar and one maple Diplomat that I made at the very start. The maple diplomat is ugly but it smokes really well.

I honestly don't know where this is going other than I'm having fun, it is keeping my days full, and I'm learning lots. Will I ever get to the point where I make pipes that look and perform well enough to sell? I highly doubt it though it's kind of fun to fantasize about becoming the next great pipe master and artisan because God knows, the world needs yet another pipe maker.

Anyone can make a pipe from a piece of briar. The huge difficulty is making a piece of art. That person is an artisan and their are a lot of them here on this forum whom I highly respect.

One of the interesting things that is a by-product of my putting rasp to briar is that now when I look at pipes to satisfy a PAD moment I think to myself, "I think I will make myself one of those and save myself a lot of money and have a ton of fun in the process." I'm not in any way knocking pipe makers be they artisans or companies, I'm just saying it's fun to be able to look at a pipe and attempt to make something that more or less, no doubt mostly less is a facsimile of the pipe I want to buy and then load it with some tobacco and puff away.