@rmbittner - Your referenced post is what prompted me to start this thread.

@chilllucky - I've been reading lots of stuff on various university websites for some time now but it's mostly a lot of agricultural and/or government regulation information. I'm thinking of sending an email about some tobacco varieties (the tables remind me of corn variety information from where I grew up in Nebraska) to the author of many of the University of North Carolina articles and seeing if I get a response.

I did find this section of the NC State Extension - 2021 Flue Cured Tobacco Information Guide very interesting and informative:

"

Curing Phases

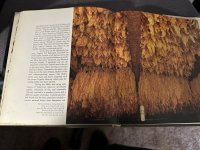

Typically the curing schedule is divided into three phases defined as yellowing, leaf drying, and stem drying. The actual curing schedule used will deviate due to factors such as tobacco ripeness and maturity, weather conditions during the growing and harvest seasons, airflow, and other influences. Tobacco harvested from different fields on the same farm may cure differently when exposed to the same curing environment. Use a temperature schedule based on your curing experience and the tobacco’s response to the curing environment. Growers have control of the dry-bulb temperature, relative humidity, and time variation of both during the curing process.

Yellowing involves a delicate balance between maintaining a high relative humidity and removing as much moisture as possible without excessive drying. A freshly harvested mature tobacco leaf is approximately 80% to 90% moisture content (wet-basis) and 10% to 20% solids. The moisture content is highest with lower-stalk tobacco and decreases with stalk position. The leaf is alive and metabolically active during yellowing and the biochemical processes continue until terminated by high temperatures or desiccation. The goal is twofold: to allow completion of the biological and physiological processes occurring in the leaf and to avoid overdrying or setting the color green. As sufficient moisture is removed during yellowing, the drying and leaf wilting will also help to improve airflow through the tobacco. The rate and extent of the biochemical reactions are controlled by temperature and moisture. Starch conversion to sugars and the chlorophyll breakdown are independent processes, but occur simultaneously and at about the same rate. As a result, optimum sugar accumulation will occur when most of the chlorophyll has degraded and the yellow pigment becomes visible, which is a visual indicator for growers to assist them with when to make changes during the curing process.

As curing progresses, the difference between the dry-bulb and wet-bulb temperatures increases, and the relative humidity decreases. When air is heated without changing the moisture content, both the dry-bulb and wet-bulb temperatures will increase. The dry-bulb temperature will increase more than the wet-bulb temperature, thus decreasing the relative humidity. The maximum dry-bulb temperature advance rate recommended is 2°F per hour during leaf drying and no more than 3°F per hour during stem drying. This gradual increase allows sufficient time for the moisture removal to keep up with the temperature increase, therefore minimizing the possibility of leaf scalding.

As long as the leaf retains sufficient moisture, the wet-bulb temperature and leaf temperature are approximately the same. If the leaf temperature exceeds approximately 113°F, the cells die, which produces browning or scalding. This is a result of too high a wet-bulb temperature and a slow drying rate. Therefore, after yellowing, the wet-bulb temperature should never exceed 105°F until the leaf lamina is completely dry. Once the leaf is dry enough to advance the dry-bulb temperature above 135°F, maintaining a wet-bulb temperature of 110°F will reduce fuel consumption. Many growers rely on experience to manage ventilation, but accurate control and minimizing fuel consumption requires monitoring the relative humidity.

Curing experience as well as knowledge of curing principles are needed to produce consistent high quality cures. Poor leaf quality is not improved during curing, even with ideal curing conditions and lots of curing experience, but the final quality of very good and poor quality leaf loaded in the barn can be significantly reduced with improper curing conditions. The potential quality of the cured leaf is determined in the field and as a result, the first step is to start with uniformly ripe tobacco. This tobacco requires less time curing and yellows more uniformly during curing. Even growers with a lot of curing experience can have curing-related issues when there are extreme fluctuations in the weather conditions, typically over a short period of time, during the season that significantly stresses the plant. This has been the case for many locations in recent years. As a result, many questions are generated on how to change the curing schedule to maximize leaf quality. This is complicated even more when your tobacco contracting entity wants a particular cured leaf style or color. Unfortunately, there is not a simple answer. Detailed curing guidelines from a late-‘70s Powell Manufacturing bulk barn operating manual are posted on the Tobacco Growers Information Portal (

https://tobacco.ces.ncsu.edu/). The manual includes discussions of typical dry- and wet-bulb temperature schedules, suggested adjustments for both that are potentially required for multiple kinds of tobacco (lower-stalk, normal, over-ripe, heavily fertilized), and various conditions encountered during curing. A general guideline is to slow down the processes of yellowing and leaf drying for tobacco that is grown under stressed conditions. The tobacco will not release moisture easily and as a result, drying too fast will negatively affect the cured leaf quality."