My grandfather died in 1935.I ended up with his homemade corn cob pipe.He was a farmer and probably grew tobacco since he lived in Virginia.This pipe is so tiny I am wondering what he used it for.Testing what he grew? It's just too small for regular smoking..

A Question Regarding a 1935 Cob

- Thread starter runningbare

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Watch for Updates Twice a Week

So two things:

1. Post a picture if you can.

2. There’s all sorts of tiny pipes out there, corncob, briar, Meershaum. Some are for quick smokes and others who knows. Souvenirs or trinkets.

1. Post a picture if you can.

2. There’s all sorts of tiny pipes out there, corncob, briar, Meershaum. Some are for quick smokes and others who knows. Souvenirs or trinkets.

Most “home made” cob pipes would probably be pretty small. Regular corn doesn’t usually have a big enough cob to make a pipe of much size. MM uses corn specifically tailored for having a larger cob. I believe I tried to make a home made cob pipe once upon a time and decided the cob was just too small. It’s very cool that you have one of his. I also would love to see a pic of it.

I don't know how to post pictures..I'm old and no kids here to show me. ha. It's smaller than a regular cob in diameter like he went out of his way to get a really small one..It must have been used for sampling tobacco they must have cured it themselves.He died of a heart attack while pulling corn stalks for livestock feed prob. He still had them clutched to his chest. They didn't find him until the next day they must have had a lot of land.

I don't know how to post pictures..I'm old and no kids here to show me. ha. It's smaller than a regular cob in diameter like he went out of his way to get a really small one..It must have been used for sampling tobacco they must have cured it themselves.He died of a heart attack while pulling corn stalks for livestock feed prob. He still had them clutched to his chest. They didn't find him until the next day they must have had a lot of land.

All guesses and speculation but here’s my take on it

In 1935 a really good factory made Missouri Meerschaum was maybe a dime at the general store.

And in 1935 I’ve heard my father say a field hand might make fifty cents a day in Missouri. As you went further South wages decreased.

The Missouri corn cob pipe industry was and still is located by fertile second bottom river land where all corn, hybrid or not, has grown fat and plentiful.

A corn cob from an upland farm tends small. I made one fifty years ago and the chamber wasn’t much larger than a pencil.

It might be a handmade pipe from the crib.

The second thing is there were two kinds of tobacco farmers in 1935.

The ones who sold leaf to dealers for cash harvested their crops and did it for profit sold cured, but not aged leaf.

The others were trying to save a nickel on a sack of tobacco in the store and they cured and aged their own “long green”.

The odds are the family saved the corn cob he smoked as a keepsake.

Men didn’t sample tobacco in 1935, they smoked it.

To further delve into Depression era cob pipes, there was a range of prices and sizes of factory cob pipes.

The largest Missouri cob pipe industry was in Washington Missouri and is the only survivor.

But from 1912-1954 there was an enormous cob pipe factory in Boonville Missouri named Phoenix American that sold a full range of cob pipes.

I bought a couple of these, new old stock, for $25 on eBay a couple or so years ago. There must have been an old box chock full of Phoniex American new old stock pipes found. They are tiny, have no plaster, and a simple reed stem. The cheapest pipe in the store in 1935.

They are still on eBay, buy all you want.

Does your grandfather’s pipe look like these?

A merchant in 1935 bought these by the gross for resale.

The largest Missouri cob pipe industry was in Washington Missouri and is the only survivor.

But from 1912-1954 there was an enormous cob pipe factory in Boonville Missouri named Phoenix American that sold a full range of cob pipes.

I bought a couple of these, new old stock, for $25 on eBay a couple or so years ago. There must have been an old box chock full of Phoniex American new old stock pipes found. They are tiny, have no plaster, and a simple reed stem. The cheapest pipe in the store in 1935.

They are still on eBay, buy all you want.

Does your grandfather’s pipe look like these?

A merchant in 1935 bought these by the gross for resale.

Yes but the cob is smoother than these.The overall L.is 3.5 in. The bowl is 1 in. tall 7/8 W. OD.

In further research I came across this application for the Historic Register of the Phoenix American pipe company in Boonville.

Until 1895 anyone could make a sell a small cob pipe left unplastered and with a reed stem. But after Tibbe’s patent for a plastered cob pipe expired the industry exploded.

But by 1920, Missouri was about the only producer, making 26 million cob pipes a year worth only a penny each, or $260,000.

Until 1895 anyone could make a sell a small cob pipe left unplastered and with a reed stem. But after Tibbe’s patent for a plastered cob pipe expired the industry exploded.

But by 1920, Missouri was about the only producer, making 26 million cob pipes a year worth only a penny each, or $260,000.

Yes but the cob is smoother than these.The overall L.is 3.5 in. The bowl is 1 in. tall 7/8 W. OD.

If it’s a smooth cob it was almost certainly factory made in Mossouri.

The raw cobs are plastered and then turned on a lathe. That was part of Kibbe’s patent.

Then a little better grade, has a wooden dowel plug in the bottom.

The basic stem was a simple reed.

Later on a better stem was a lathed or machine cut small corncob with a plastic tip.

Today they use a wooden dowel with a plastic stem.

The really big hybrid cobs came out in the late forties.

Before that though, there was a variety called Collier’s that made bigger cobs than most.

My grandfather died in 1952, a prosperous farmer who owned 160 acres of fertile land.

I have his Hammer Brand pocket knife that likely cost a dime of fifteen cents.

The cheapest Chinese gas station knife sold today looks like a Case in comparison.

It was the last one he didn’t lose or break the blade and buy another.

This is a far better model than his.

Last edited:

My dad and uncle were the first in our family that were not farmers for an occupation . According to Ancestry.com.

My dad and uncle were the first in our family that were not farmers for an occupation . According to Ancestry.com.

I’m the first in a dozen generations not a farmer, except my mother’s father made a small fortune out in the Pacific Northwest in three years around 1900 and bought 2,000 acres of bottom land and was a landlord farmer.

Look at the plaster in between the cracks of the modern large hybrid cob, tightly grained cob. This is a small pipe.

Corn farmers wanted bigger holes for bigger kernels and the pipe makers wanted smaller kernels.

And of course the farmer wanted less cob and more corn.

A cob pipe in 1935 was a disposable.

In a way they still are, but we don’t run around doing farm work in bib overalls with them, you know?

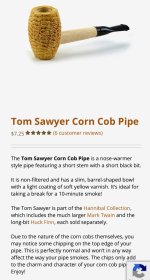

Looking at the dimensions of the Sawyer, that's a 30-40 minute pipe.The idea of a small cob is a cigarette length smoke.

The only grain on a cob are the kernels.tightly grained cob

The only grain on a cob are the kernels.

If you look at the really old cob pipes they’ll have large areas where a kernel was. If you smoke one without resting those large pieces of cob get crumbly and flake off. Newer cob pipes use tighter grained cobs that had smaller kernels.

Irvin S Cobb

Missouri Meersschaum began commercial cobs but until 1975 or so they had lots of competition.

The first cobs were natural cobs with a reed stem. Now, they weren’t just any cob, but cobs that would not fit through a ring the factory provided farmers.

The companies advertised to farmers they’d get about ten dollars an acre for the cobs, if they’d plant a certain variety of corn. Back then corn was either hand picked and shucked or a mechanical corn picker was used. The cobs were good only as fuel or toilet paper, if there wasn’t a pipe factory around. $10 an acre was a BFD.

My family started planting hybrid corn early on my father said, using Funk’s.

A Brief History of the Hybrid Corn Industry

(Last revised January 4, 2020) Corn is the biggest agricultural success story of the Americas, from its beginning as a wild grass 7000 or more years ago in Mexico to become one of three dominant fo…

The entire goal of the hybrid corn seed makers was to increase the yields of corn. Cobs were waste.

Why Missouri Meerschaum survived was they used a geneticist at the University of Missouri to develop a hybrid seed maximizing the size of the cobs and shrinking the size of kernels so their pipes would be tightly grained and larger. Since then MM contracts for cobs and the corn is the waste product, fed to livestock.

There is a fascinating museum at the Washington factory you can spend a day looking at the exhibits.

The Chinese make an inferior knock off of genuine MM pipes, but they cannot in any way compare to the real ones.

Here’s a $7 little MM Pony Express

At one time MM and other makers fabricated the shank from cobs.

That’s the reason for the printed kernel pattern on the dowel rods they use today. I’ve noticed more pipes don’t have the cob pattern on the shank.

Last edited: