Here’s a pipe I purchased twice. The first time it was scooped up by the corrupt eBay Global Shipping scumbags, and the second time by their resellers eBay UK. The funny part the reseller used Royal Airmail. The price was roughly the same, both times all in all.

When it arrived I knew the stem was compromised, but didn’t realize it was literally going to fall apart while smoking.

So, off to Ryan Alden it went.

We always have a back and forth about the pipes he examines and we make a plan. He already knows I don’t want black stems on my pipes that are fully restored. It doesn’t feel right even though his stem work is better than and factory on the planet.

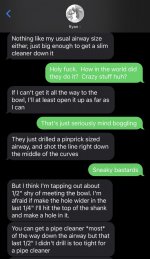

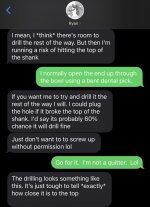

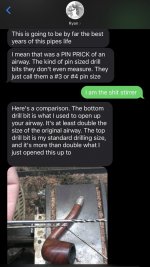

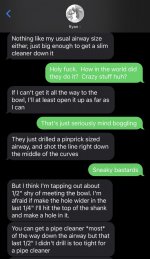

So I think the best way to show this process is to screen shot the texts and post some photos. The process was very interesting.

The pipe smokes wonderfully and I’m extremely grateful for Ryan’s skill set and my luck ahaving him do this.

In short, he reworked the briar bowl, redrilled the shank, removed the bone tenon and made a new stem.

In a word…. GLORIOUS.

The first photo is how it arrived. Followed by the finished product then the series of screenshots of text dialogue. I’m easy to spot. I’m the idiot in the green bubble.

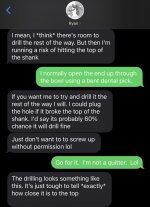

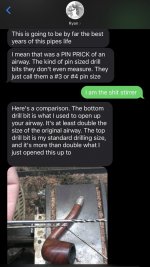

The action picks up after the decision to re-drill the draft hole and the process is underway. We made an agreement that if a drill through occurred it would be dealt with. Ryan was real sensitive about boring through an 1896 pipe.

When it arrived I knew the stem was compromised, but didn’t realize it was literally going to fall apart while smoking.

So, off to Ryan Alden it went.

We always have a back and forth about the pipes he examines and we make a plan. He already knows I don’t want black stems on my pipes that are fully restored. It doesn’t feel right even though his stem work is better than and factory on the planet.

So I think the best way to show this process is to screen shot the texts and post some photos. The process was very interesting.

The pipe smokes wonderfully and I’m extremely grateful for Ryan’s skill set and my luck ahaving him do this.

In short, he reworked the briar bowl, redrilled the shank, removed the bone tenon and made a new stem.

In a word…. GLORIOUS.

The first photo is how it arrived. Followed by the finished product then the series of screenshots of text dialogue. I’m easy to spot. I’m the idiot in the green bubble.

The action picks up after the decision to re-drill the draft hole and the process is underway. We made an agreement that if a drill through occurred it would be dealt with. Ryan was real sensitive about boring through an 1896 pipe.