Plants Used To Be Built In USA

- Thread starter tbradsim1

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Self wiping laptops?. . . self wiping laptops!

Wait, I don't think I want to know.

A lot of things used to be built in the US. I’d like to see the pendulum swing back our way again. It looked like it was just beginning to, pre-COVID.

It's capitalism. Capital follows cheap labor.View attachment 49389

Sons unit destined for Corpus Christi leaving China, takes 2 months then goes back again for more. We used to build them here, I helped build one of the biggest at the time Ethylene Unit. Traveresty!

Keep your expenses low, foster your debts on someone else, and you'll prosper!

There used to be a work force in the USA that would work and show up every day. There still a lot of manufacturing here though.

I think Buicks are built in China now. Cars actually assembled here have mostly parts from other countries. I don't even understand how the components of those prefab plants are unloaded -- big cranes and huge trucks? I'd like to set up a lawn chair and be a spectator.

Son was just on a project in Baytown building a new unit, it came from Indonesia, Exxon rented NASA CRAWLER to take big tower off ship and move to site. When you have money nothing is out of bounds.

I have a quite a collection of truly exquisite American made pocket watches. Alas not made there anymore.

Some of these watches are over 100 years old and with careful regulation most can be made to run within 10 seconds per day. Quite remarkable really.

Regards,

Jay.

Some of these watches are over 100 years old and with careful regulation most can be made to run within 10 seconds per day. Quite remarkable really.

Regards,

Jay.

I gave up when Levi's was made outside of USA. Now all the clothes fit like crap. One jean to other doesn't fit the same. We need to bring everything back to America. At least, not in China.

I think Buicks are built in China now. Cars actually assembled here have mostly parts from other countries. I don't even understand how the components of those prefab plants are unloaded -- big cranes and huge trucks? I'd like to set up a lawn chair and be a spectator.

I believe one model is made with a joint venture in China. They're manufactured in other countries as well. They are sold in other countries as well. Many Japanese, Korean and German vehicles are assembled here in the USA. Some component parts and assemblies are made offshore, many are still made here in the USA.

I gave up on Levi’s when they started getting political.I gave up when Levi's was made outside of USA. Now all the clothes fit like crap. One jean to other doesn't fit the same. We need to bring everything back to America. At least, not in China.

I gave up on Levi's when I got fat.I gave up on Levi’s when they started getting political.

Definitely cotton fabric used on those jeans which were manufactured in the U.S was of better quality

View attachment 49389

Sons unit destined for Corpus Christi leaving China, takes 2 months then goes back again for more. We used to build them here, I helped build one of the biggest at the time Ethylene Unit. Traveresty!

Respectfully, the other side of this coin is that the US is adding ethylene production capacity a steady rate for the next five years, to the tune ~5-7MT per year. Moreover, we are increasingly exporting the stuff we pull out of the ground and process (from LNG to ethylene/PE/MEG). Finally, China can't meet domestic demand for these chemicals, so from another perspective, this unit, made in China, will produce material in the US, of which China will be a major customer.

I can imagine how cool it must have been to be a part of a huge project like that, back in the day. These facilities are so vast, complicated, such engineering marvels! So, I can appreciate it may feel like a loss. Still, the puts-and-takes are favorable domestically (more refinery jobs, more downstream jobs in plastic production, fuller use of upstream feedstocks, etc.).

Best,

Lee

Just to play devil's advocate. I work in the manufacturing industry and I see how the "new" generation of factory workers are and I wonder how long my factory will stay open. This new group feels entitled to to much. I hear on a weekly basis " they are lucky I even showed up today"

It makes you wonder how we keep the doors open

It makes you wonder how we keep the doors open

Here in Alabama, everyone was so excited to get Mercedes, Honda, and Toyota plants. Our state gave them tax free passes, the county gave them free land, and they completely automated, so that they add absolutely zero jobs. We got screwed hard. And, when the contract is up, they'll be run out of here tarred and feathered. Fuck them companies. They add nothing to the numbers.Many Japanese, Korean and German vehicles are assembled here in the USA.

My daughter's fiancé worked at a company that made crates and palates, and it was hard work, mostly hand built. They were getting screwed at $18 an hour, which is way below being able to take care of yourself in this area, much less a family. A few months ago, they completely automated their jobs. Pink slips. Empty parking lots now.

We may have places where manufacturing is still happening, but if they haven't moved to China, they're automated. What ever they can do to kick hard working American's in the teeth for a few bucks.

My daughter's fiancé worked at a company that made crates and palates, and it was hard work, mostly hand built. They were getting screwed at $18 an hour, which is way below being able to take care of yourself in this area, much less a family. A few months ago, they completely automated their jobs. Pink slips. Empty parking lots now.

^^This^^

While it depends on the industry, manufacturing task, degree of standardization, etc., the rational capital/labor trade for robotics is ~$15-$35 per hour range. In short, if you're making that, you're at risk. Worse, the price/performance of robotics falls ~10-15% per year (a la "Moore's law"). That means the capital/labor trade will encroach even the lowest paying jobs. It's a serious challenge; I'm skeptical that we're up for it.

Lee

As someone who's been laid off about 200+ times, I feel the pain.

Manufacturing is huge in the US. It's just largely automated.

I've retrained several times in the course of my "illustrious" career in order to stay current and relevant in my field, and did it on my own dime. I've learned new technologies and now methodologies, and in a few cases as an early adopter, created some of those methodologies now in use. I've taught hundreds of people new skills so that they can remain employed and/or employable.

You have to adapt or wind up in the rubbish.

Manufacturing is huge in the US. It's just largely automated.

I've retrained several times in the course of my "illustrious" career in order to stay current and relevant in my field, and did it on my own dime. I've learned new technologies and now methodologies, and in a few cases as an early adopter, created some of those methodologies now in use. I've taught hundreds of people new skills so that they can remain employed and/or employable.

You have to adapt or wind up in the rubbish.

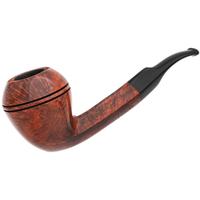

There are many reasons our manufacturing moved off shore. One of the most serious is, Americans like to buy cheap. Whether it be autos, jeans, pipes, toys, dog food, shoes, TV's, etc., cost is a preeminent consideration for many consumers. Ergo,, American businesses and their shareholders move to avoid taxes they must push down to their customers so, they move offshore to keep costs lower. Remember, consumers pay the taxes, not the corporations. American labor, though it may be very good, is expensive when compared to other locales. As Pogo once observed, "We have met the enemy and, he is us."

Here in Alabama, everyone was so excited to get Mercedes, Honda, and Toyota plants. Our state gave them tax free passes, the county gave them free land, and they completely automated, so that they add absolutely zero jobs. We got screwed hard. And, when the contract is up, they'll be run out of here tarred and feathered. Fuck them companies. They add nothing to the numbers.

My daughter's fiancé worked at a company that made crates and palates, and it was hard work, mostly hand built. They were getting screwed at $18 an hour, which is way below being able to take care of yourself in this area, much less a family. A few months ago, they completely automated their jobs. Pink slips. Empty parking lots now.

We may have places where manufacturing is still happening, but if they haven't moved to China, they're automated. What ever they can do to kick hard working American's in the teeth for a few bucks.

As of April 30, 2020, the Mercedes Alabama plant employed over 4,000 people. That only brushes the surface of what having a plant like that in the area does for the positive. There are thousands if not tens of thousands of other people, in the immediate area, who make income from that plant. Machine shops, mold shops, transportation, food and hotel, etc.. You are being extraordinarily short sighted if you think that plant doesn't benefit the local economy immensely. I've seen very close up the devastation left when a large automotive plant closes the doors. Ask Muncie, Anderson and New Castle Indiana if they'd like their automotive plants back.

While the company itself may get many tax incentives and freebies, how about the income taxes on those 4,200 employees? If the average income is $40,000, that generates $168M in taxable income. At a 30% tax rate, that's over $50M in Federal taxes created. When you add in all the other jobs created in the area, well over $100M in Federal taxes are paid. And even with Alabama's low State Income Tax, at even 3% on average, over $5M in State Income taxes are paid.

Most automotive companies also provide fairly reasonable health insurance benefits. Where are all those people going to find comparable jobs with health insurance benefits near Birmingham?

Automation does not eliminate all jobs. You been watching too many Terminator movies. It does indeed decrease the number of manual labor jobs which would be, of course, lower in pay. However, it creates many more technical jobs for people to operate and maintain the machines.

- Status

- Not open for further replies.