By Russ Ouellette

The curing of tobacco is sometimes likened to alchemy or subatomic structure by some pipe smokers. The fact is that curing is just a method of preparing the leaf for further processing, or for immediate use, usually by using a procedure which minimizes or eliminates certain inherent negative qualities. The main methods of curing include: air curing, flue curing, fire curing, sun curing (although some people consider this the same as air curing), fermentation by pressure (as in the case of Perique) and fermentation by bulking, which is used mostly for cigar tobacco. Let’s look at each process, what it does and with which tobaccos each method works best.

The curing of tobacco is sometimes likened to alchemy or subatomic structure by some pipe smokers. The fact is that curing is just a method of preparing the leaf for further processing, or for immediate use, usually by using a procedure which minimizes or eliminates certain inherent negative qualities. The main methods of curing include: air curing, flue curing, fire curing, sun curing (although some people consider this the same as air curing), fermentation by pressure (as in the case of Perique) and fermentation by bulking, which is used mostly for cigar tobacco. Let’s look at each process, what it does and with which tobaccos each method works best.

Air curing is pretty much what you would expect- curing by allowing the leaves to dry by exposure to open air. This process can also include using fans to force air movement to accelerate the loss of moisture. This type of curing is used primarily for dark Burley, often referred to as dark air cured, which is a, typically, mahogany-brown leaf with a spicy, earthy flavor and a significant nicotine kick. Most cigar leaf is cured this way as well, although it will also undergo an extra step, often referred to as "bulking" in which the leaves become fermented. The pH level of dark air cured is on the alkaline side, which works in concert with the nicotine to cause a "rush" (more on this later). The pepperiness of certain natural tobaccos, such as dark Burley and many of the Central American-grown Cuban-seed cigar strains comes from the nicotine inherent in the leaf.

Air curing is pretty much what you would expect- curing by allowing the leaves to dry by exposure to open air. This process can also include using fans to force air movement to accelerate the loss of moisture. This type of curing is used primarily for dark Burley, often referred to as dark air cured, which is a, typically, mahogany-brown leaf with a spicy, earthy flavor and a significant nicotine kick. Most cigar leaf is cured this way as well, although it will also undergo an extra step, often referred to as "bulking" in which the leaves become fermented. The pH level of dark air cured is on the alkaline side, which works in concert with the nicotine to cause a "rush" (more on this later). The pepperiness of certain natural tobaccos, such as dark Burley and many of the Central American-grown Cuban-seed cigar strains comes from the nicotine inherent in the leaf.

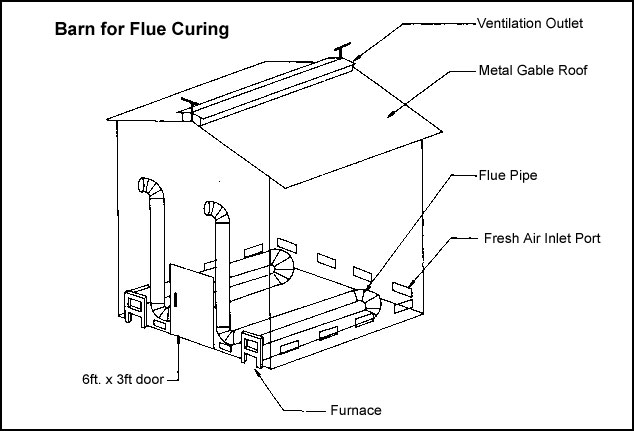

Flue curing is curing by exposure to indirect heat, created by moving hot air, smoke or steam through a flue or pipe, and allowing the heat to radiate to heat the enclosure it’s housed within. The higher heat causes a more rapid drying effect, and is the traditional method for curing Virginia or Brightleaf, which gets its yellow color from the heat exposure. Flue cured tobacco generally has more sugar, less oil and a lower nicotine content. The presence of the sugar also leads to a lower pH, which may lead to a decreased propensity for this type of leaf to cause tongue bite, but can cause heat issues, as the sugars tend to result in a higher combustion temperature. Because of the ability of this curing method to "fix" sugars (maintain the sugars in a relatively stable percentage), a form of flue curing is used in making candela (green) cigar wrapper, as the heat not only fixes the sugars (which are fairly low in cigar leaf) but the chlorophyll as well, allowing the wrappers to stay green.

Flue Cure Barn Near Lawsonville, NC © 2011 Phil Ross (Used with permission)

Fire curing is the tobacco equivalent of barbecuing. With this method, the leaf is exposed to open fires (smoldering rather than blazing) that give off smoke. In some cases, the amount of smoke is fairly moderate. Dark fired Kentucky (a form of Burley) has a modest smokiness that adds a woodsy bite. Latakia is also a fire cured tobacco, but with a far more pronounced smoke flavor and aroma due to the intensity of the fumes and aromatic quality of the wood used. The nicotine content and pH don’t seem to be severely affected by this process, as dark fired Kentucky, which has a significant nicotine level and a fairly high pH is not that much different than dark air cured; and Latakia’s moderate nicotine level and pH don’t vary all that greatly from the base leaf it is made of (in Cyprus- Smyrna; in Syria- Shek-al-Bint).

Sun curing is used mostly for Oriental varietals. Since I don’t have any real data about trying different curing methods on these strains, I can’t really determine the impact is has on the chemistry of the leaf, other than the idea that some of the sugars are likely to caramelize, but Oriental tobaccos tend to be rather average in nicotine, but tend toward slightly acidic to somewhat alkaline due to a relatively low sugar content.

Editor’s note: "The Pipe Smoker’s Tobacco Book" by Robert F. Winans describes Oriental tobaccos as being the lowest in nicotine with a moderate amount of sugars. I brought this to Russ’ attention and he responded; "Both are correct, in a sense, since there’s quite a range of nicotine and sugar levels among around 40 different strains of Orientals."

Additional or supplementary curing can be accomplished by the use of heat and/or pressure after the initial drying phase. Fermentation is a typical side effect which will have a significant impact on the finished product.

In the case of Perique, the leaves are packed in barrels and subjected to pressure from a screwjack which bursts the cells and the resulting juices then ferment and are reintroduced to the leaf at a later time. A year’s worth of fermentation helps develop deeper flavor and a bit more sweetness than the base leaf exhibited. Because Perique is an offshoot of Burley, it tends to be fairly alkaline and has a decent amount of nicotine, so it may feel like the level is higher than it actually is. Greg Pease made note of this phenomenon in a recent article- a tobacco with a higher pH will help the body absorb nicotine at a greater rate, and since alkaline tobaccos tend to produce more alkaline smoke further down the bowl (or down the cigar), the effect of the nicotine can be even more pronounced toward the end of a smoke.

Since I’m already on the subject, acidic smoke causes nicotine to be absorbed less readily, and tobacco that is higher in sugar produces a more acidic smoke, so strains such as Virginia work well for cigarettes as the lower nicotine content and acidic smoke allow inhalation with less harshness and discomfort. It’s just as well that the mechanism works this way, as inhalation of alkaline smoke with moderate to high nicotine levels could bring about some of the less desirable effects of "vitamin N", such as light-headedness, hiccups (the "nic-hics"), rapid heart rate and/or queasiness. Likewise, the harshness of the stronger, more alkaline strains make them ideally suited to cigars and pipes which are generally not inhaled, so the higher content is absorbed more gradually through the membranes of the mouth and salivary glands.

Pressure is also used in making flakes, cakes and ropes. Some pressed tobaccos seem to have inconsequential amounts of nicotine, while some (like the Lakeland types) are very strong. It would seem that the process has more to do with the alkalinity than nicotine, as the nicotine level doesn’t vary all that much due to pressing, but it should also be noted that, despite common belief that Lakeland flakes are mostly Virginia, many of them have significant amounts of dark Burleys. Also, a lot of them use Virginias from other parts of the world with lower sugars and higher nicotine.

"Bulking" is fermentation produced by piling bales of tobacco (called bulks) until the pressure creates the onset of fermentation and then the temperature is closely monitored, as the temperature has a major influence on the flavor and the color of the finished leaf. Maduro wrappers, for example, might be fermented up to 140 to 160 degrees Fahrenheit to produce the dark brown color. The heat doesn’t seem to have a great impact on (nicotine) strength, but the higher heat will tend to sweeten the leaf as some of the sugars become caramelized.

There’s a lot more to the processes and chemistry than this space will allow, and my hands-on experience with some of the methods is minimal, but I hope that this has made things a bit easier to understand.

If you have ideas for other topics to explore, email me at the address below, or leave a comment.

|

Russ Ouellette is the blender/creator of the Hearth & Home series of tobaccos for Habana Premium Cigar Shoppe and www.pipesandcigars.com in Albany, NY. He has been a pipe smoker and blender for over 30 years, and enjoys feedback from the pipe smoking public. You can reach Russ at russo@pipesandcigars.com or by calling 1-800-494-9144 on Monday, Wednesday and Thursday from 9 am to 5 pm and Friday from 1 pm to 5 pm. |

Great read, Thanks Russ!

Russ, a very blue collar and enjoyable read.

You answered a lot of questions I didn’t know I had been asking.

Thank you.

Definitely worth a second read.

Excellent article, thanks Russ.

It’s easy to forget how much work can go into that tin or pouch of tobacco. Or should I say “a labor of love”. Thanks Russ for another interesting article.

Awesome read, Russ. I know I’m just learning many of the steps and procedures that go into the blends I love, but you have a great way of explaining it all.

I love these behind the scenes article. Great work again Russ!

Fun read. I especially appreciate the picture showing Perique being pressed.

The quality handwork and dedication of this industry is outstanding !!

Thank you for this article !

Another outstanding and informative article. Thank you Russ. Knowing how our favorite blends come into existence after the harvest really adds to the enjoyment of the experience.

Simply superb, concise and informative.

You are to be commended! A lovely, yet simple and easy to understand insight to curing. Congratulations!

Great read and very informative!

Thanks.

FWIW, all the tobacco grown in my area of TN is fire-cured Burley.

This is simply a “must read” article for all pipe smokers!!