G. L. Pease

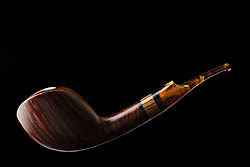

As I sit down to compile this month’s column, I’m smoking a lovely little Peter Heeschen briar, in his signature P shape, filled with a prototype blend that I’ve been obsessing over for some time, and which is finally approaching the point where I am ready to move it towards production. Now begins the process of finalizing everything. Scaling batches from what I do to the final form can be, um, interesting. When I work on new blends, I do everything in small quantities, so there are often some minor changes that have to be made before taking the product live. It’s an exciting part of the process for me, but can be rather nerve-wracking, as well. Not often, but sometimes, I’ll get the first "productized" samples, and find it so different from what I’d become familiar with that I end up doing a lot of head-scratching while attempting to figure out how to bring things back on track. It’s turns out this is a strangely inexact science, really. What works in tiny, precisely measure quantities, made in my underground laboratory doesn’t always translate to large, precisely measured quantities, made at the factory. It usually goes relatively effortlessly, but sometimes, it’s the little things that end up being amplified to more dramatic distortions at production volumes. And, even after having been doing this for over a decade, when I’m at this point in the development cycle, I always feel like I’m starring in my own private episode of Fear Factor. So far, I’ve managed to make it to the final cut of each season, but it doesn’t get any less uncomfortable to know that something could go wrong. Blame it on gamma rays, and their effect on Man in the Moon Marigolds. (Apologies to Paul Zindel.)

As I sit down to compile this month’s column, I’m smoking a lovely little Peter Heeschen briar, in his signature P shape, filled with a prototype blend that I’ve been obsessing over for some time, and which is finally approaching the point where I am ready to move it towards production. Now begins the process of finalizing everything. Scaling batches from what I do to the final form can be, um, interesting. When I work on new blends, I do everything in small quantities, so there are often some minor changes that have to be made before taking the product live. It’s an exciting part of the process for me, but can be rather nerve-wracking, as well. Not often, but sometimes, I’ll get the first "productized" samples, and find it so different from what I’d become familiar with that I end up doing a lot of head-scratching while attempting to figure out how to bring things back on track. It’s turns out this is a strangely inexact science, really. What works in tiny, precisely measure quantities, made in my underground laboratory doesn’t always translate to large, precisely measured quantities, made at the factory. It usually goes relatively effortlessly, but sometimes, it’s the little things that end up being amplified to more dramatic distortions at production volumes. And, even after having been doing this for over a decade, when I’m at this point in the development cycle, I always feel like I’m starring in my own private episode of Fear Factor. So far, I’ve managed to make it to the final cut of each season, but it doesn’t get any less uncomfortable to know that something could go wrong. Blame it on gamma rays, and their effect on Man in the Moon Marigolds. (Apologies to Paul Zindel.)

Photo © 2012 G.L. Pease. Used with permission.

So, with that in mind, I’ve chosen a couple of questions that concern the process of blending to begin this month’s issue, with the hopes that it will be of broader interest, and it doesn’t just end up reading like some sort of vanity post. Lord knows, there’s enough of that to go round.

So, with that in mind, I’ve chosen a couple of questions that concern the process of blending to begin this month’s issue, with the hopes that it will be of broader interest, and it doesn’t just end up reading like some sort of vanity post. Lord knows, there’s enough of that to go round.

Without further ado, here we go.

Darren writes: When you are creating a blend, do you account for the smoke from the combusted tobacco affecting the flavor of the unburnt tobacco in the bowl? Does it even matter? I was thinking about this the other day as I was smoking a salmon fillet. I like fruitwoods for smoking salmon as opposed to hickory or mesquite. You can really tell the difference in the end product. I’m just wondering if the smoke from combusted tobacco has as much of an effect on the overall flavor as your progress through a bowl. Hmmm… maybe your next blend should be called "Old Hickory" and you could put a couple of hunks of wood in it.

A: You were smoking a salmon fillet? I imagine that was a little hard to keep lit…Okay, okay. I’ll be here all week. Don’t forget to tip your waiter.

It’s an interesting question, and a difficult one to answer completely. The aroma of the smoke does make a contribution to the overall experience of smoking a blend, and when that smoke is drawn through the unburned tobacco, it certainly influences the flavor. There are several things finding their way into the smoke stream, and all of them are important to the final enjoyment. The smoke from the burned tobacco carries some interesting aromatic components with it, as it passes through the tobacco on its way to the smoker’s tongue. The warm water vapor (always present as a byproduct of combustion, even if the tobacco itself is quite dry) brings with it some sweetness and other soluble flavors, and some of the more volatile components in the unburned tobacco are activated by greater temperature, and also enter the mix. Next time you fill your pipe, draw through it several times, and see what you taste. Then, see how much different it is with just a little charring, and then the final lighting. While smoking, puff out just a bit, and then draw the smoke back through the bowl. It’s actually quite remarkable how much difference there can be in the smoke by simply varying technique a little.

Smoked meats are similar to fire cured tobaccos, like Latakia, in that the smoke particles are deposited on and penetrate the surface of the product, and the warm smoke itself, though it isn’t part of the eating experience, leaves behind its distinctive signature. When the tobacco is burned, those particles are both liberated in the smoke, and also carried through the stream by volatilization. Though there are no actual wood chunks in tobaccos, at least there shouldn’t be, there’s no shortage of wood smoke in those that contain Latakia or Kentucky dark-fired. (More on that delicious stuff further down the page.)So, yes, all these things are taken into consideration when putting a blend together. It’s part of the total package. And, I think I’ll pass on the idea of wood chips in the blend.

Gregg wonders: I am curious how do blenders maintain consistency in their blends? I assume crop yields and quality can vary year to year, not unlike grapes for wine. I hope this is not a trade secret.

Gregg wonders: I am curious how do blenders maintain consistency in their blends? I assume crop yields and quality can vary year to year, not unlike grapes for wine. I hope this is not a trade secret.

A: This would have different answers, depending on who’s doing the answering, and how honest they want to be. Just as with wine, it’s possible to maintain consistency from year to year, through the use of leaf or grape selection and blending with the product of previous years. Some manufacturers maintain leaf stocks that span several years, so they can be combined to maintain a consistent product. If you’re not shooting for the highest absolute quality possible, this isn’t really that hard to do, and the big producers do it to prevent surprises.

Further, with heavily processed, highly flavored and aromatic tobaccos, it’s easy to adjust things by the application of sauces. It’s unlikely that anyone would be able to taste the difference crop variation might provide in blends that rely on augmentation for their character. In probably many cases, the tobaccos selected for use here are chosen for their blandness, their burning characteristics, and their ability to carry sauces, not for their varietal quality.

I work differently with my blends, both because we’re too tiny to store years worth of leaf practically, because we don’t rely on additives for our products, and because I really don’t want to eliminate vintage character, especially if it’s somehow distinctive or special. If I get a particularly good vintage of a particular leaf, I’d rather go ahead and use it, letting its character shine through, even knowing that the resulting blend will be slightly different from that of previous years. If I was making single source products, those differences would certainly be more noticeable, but even with a complex mixture of many different tobaccos, you can taste subtle changes from year to year. We do strive to ensure that each year’s is as good as it can be, and the consistency is actually surprisingly high, but there are always going to be differences resulting from crop variations, and that’s just a fact of life when you’re dealing with small batch production of anything that relies on agricultural resources. And, honestly, I wouldn’t have it any other way.

Fabricio Viscardi asks: Greg, as a latakia lover, knowing that Syrian and Cyprus cousins have rather different personalities, my question would be if a blend containing both varieties blended with a good amount of quality virginias would make a good blend at all or it would be a rather waste of good smokiness and piquancy contents?

A: I’ve done several blends using both Syrian and Cypriot Latakia, virginias and orientals, and the results have been wonderful, showcasing the characteristics of both types of Latakia. The two types can really compliment each other if used in careful proportions. Generally, if using only virginias as a base, you have to be careful with the Latakia components to keep things in good balance, but when done with care, the results can be delicious.

From Stacen: Hi, I have seen quite a bit of commentary on this site and online regarding your new blend Triple Play. One of the things mentioned consistently is "Dark Fired Kentucky" as one of Triple Play’s constituent tobaccos. I don’t know much about this tobacco. Could you discuss it? One particular question I have is: Is it Kentucky leaf that has been "dark fired" (is dark firing a special curing process?) or is it Dark Kentucky leaf that has been "fired"? Thanks for providing this question and answer forum, it is much appreciated!

From Stacen: Hi, I have seen quite a bit of commentary on this site and online regarding your new blend Triple Play. One of the things mentioned consistently is "Dark Fired Kentucky" as one of Triple Play’s constituent tobaccos. I don’t know much about this tobacco. Could you discuss it? One particular question I have is: Is it Kentucky leaf that has been "dark fired" (is dark firing a special curing process?) or is it Dark Kentucky leaf that has been "fired"? Thanks for providing this question and answer forum, it is much appreciated!

A: To do this question the justice it deserves would require a complete article, as the stuff has a long history and is quite fascinating in many ways. I’ve been meaning to write something more in-depth, and if there’s interest, I’ll turn the fires up under that project, so to speak.

Briefly, dark-fired is both dark and fire-cured. These tobaccos, casually referred to as "darks," begin life as a different cultivar from the regular burleys, and include the Green River and One-Sucker varieties. Roughly 90% of these darks are grown in a small region of south-western Kentucky and across the border in north-western Tennessee, with the rest coming from Virginia, and are brought to market either air- or fire-cured.

Fire-cured darks are stalk harvested and air dried until the desired level of yellowing occurs, usually for between five and eight days, before controlled fires are built from hardwoods and sawdust. The yellowed leaf is locked away in the smoking barns to be fumigated, through as many as three distinct firings, until the desired level of color is set, the correct moisture content is achieved, and the right amount of smokiness is produced. The production is a delicate balance of art and science, as there are a lot of variables to consider during the process, such as maintaining correct humidity and temperature, and just the right smoke levels.

The finished result is a strong, dark, slightly sweet and smoky, with a distinctive tobacco, with an almost floral character. Dark-fired is not as pungent as its sun-dried, fire-cured cousin, Latakia, but it is much stronger, in general. Much of the world’s production finds its way to snuff, chewing tobacco and dry cured cigars, though it’s always been an important component in some traditional UK pipe tobaccos. There’s quite a bit more to the picture, but I hope this little thumbnail offers some insight.

Not really a Q&A, here, but several people have written in regarding the strength of some tobaccos, the gist being that there are blends that really sneak up on you, like an iron fist in a velvet glove, and much stronger than expected.

I can certainly relate! The first bowl of the original Craven Mixture I ever smoked, I recall it being in 1984, offered up a frightening tale to tell. I was heading home from the Saturday afternoon pipe gathering at Drucquer’s, smoking a bowl of this deceptively potent stuff, quite contentedly, as I drove. Craven, by the way, was the blend reputed to have inspired Barrie’s My Lady Nicotine, and after my first experience with it, I could well imagine the delirium that a regular diet of the stuff must have provided the book’s protagonist. Yes, it was delicious, and this sample was very nicely aged; a rich, full flavored, lovely blend, but one that was very deceptive in its strength. I drove. I smoked. I fully enjoyed the experience. I had no idea what fate would befall me next.

I made it home just before the full effect took hold. As I was getting out of the car, I noticed my nose was sweating. "That’s odd," I thought. Minutes later, it was the E-ticket ride on the Orleans Orbiter. (For those who have never experienced it, the Orleans Orbiter is one of the most sadistic of what I have come to refer to as the "Whirl-and-Hurl Machines" ever to haunt an amusement park. I made the mistake of getting on one once, and spent the rest of the day curled up in a fetal position in the back seat of my friend’s Buick. It ruined not only the rest of my day, but most of the following one, as well. I cannot even imagine spinning in more dimensions at one time, and even the thought of the thing turns my stomach.)

I’ll spare the gruesome details, but suffice to say that all I could do was walk around, attempting to breathe deeply. Lying down was a very bad idea, as it just increased both the magnitude and the velocity of the room’s polydimensional spinning. Ghastly memory. It took several hours before I started to get back to normal, and I didn’t have much interest in pipes for a few days after that. The tobacco didn’t seem that strong when I was smoking it, and by the time I realized it, it was too late. The moral of my cautionary tale is to treat any new tobacco you try with respect, or it might hurt you.

I’ll spare the gruesome details, but suffice to say that all I could do was walk around, attempting to breathe deeply. Lying down was a very bad idea, as it just increased both the magnitude and the velocity of the room’s polydimensional spinning. Ghastly memory. It took several hours before I started to get back to normal, and I didn’t have much interest in pipes for a few days after that. The tobacco didn’t seem that strong when I was smoking it, and by the time I realized it, it was too late. The moral of my cautionary tale is to treat any new tobacco you try with respect, or it might hurt you.

Getting back to Kevin (there sure are a lot of Kevins out there), whose question from last month I didn’t really mean to dismiss, but ended up doing so anyway. (Blame it on the pressures of a deadline when our fearless leader is breathing down my neck, figuratively, calling me every ten minutes to find out where my column is, or maybe just forgetfulness, or a lack of caffeine, or those pesky gamma rays…)

Anyway, he asked: It seems natural that tobacco would change during the course of a bowl since by time you get to the bottom, more smoke has passed through unsmoked leaf, but why do some blends change so much more dramatically than others?

A: As with so many things concerning our deceptively simple pastime, there’s a lot more to this than we’d initially suspect. As we smoke our pipes, myriad byproducts of combustion are essentially being filtered through the tobacco below the ember. Depending on how we smoke, what we smoke, the relative humidity, the pipe’s willingness or reluctance to cling to moisture, the cadence of our smoking, and many other factors, some of those byproducts will get through the "filter," some will condensate towards the heel of the bowl, or in the shank, and others will stick to the leaf to be combusted again, or volatilized when the warmth of the ember reaches them. Since the filtering action of the tobacco becomes less efficient as the bowl progresses, both because it’s becoming saturated with these byproducts at an ever increasing rate, and because as the leaf is consumed, there’s just less of it there, the smoke’s taste tends to get stronger as the bowl progresses.

Because of these mechanisms, blends with more volatile oils in their overall makeup, especially those containing high percentages of oriental varieties or latakia, and to a lesser extent, some burleys, will tend to intensify more than blends that are dominated by most virginias, though there are some types that are quite oily, and these, too, build up greater intensity during the course of the bowl.

Last month, I wrote briefly in response to a question on Navy Flake. In response to my admittedly naive view of the subject, a wonderful description came in from a new correspondent, Myles, who was able to find the following fascinating passage in W.A. Penn’s The Soverane Herbe: A History of Tobacco (p127), published 1901. Thanks, Myles, for sharing this with me and with our readers.

Little of the popular navy-cut is now prepared after the nautical manner. The generality of it is marine only in name, being pressed and cut like ordinary flake tobacco. For true naval tobacco one must make a raid on the Royal Navy. The Admiralty serves out tobacco-leaf to Jack at a charge of is. a pound, this leaf being duty-free. (No duty is exacted on tobacco consumed out of England ; before sailing, captains of merchant ships requisition from the Customs tobacco free of duty for consumption on the voyage.) The bluejacket of the Royal Navy buys tobacco in leaf from the ship’s stores. He damps the leaves—old hands use rum to strengthen and flavour—and lays them neatly lengthwise, one on top of another. This bundle he rolls up into the shape of a cigar, thick in the middle and tapering at the ends with the leaf Covered with canvas, the roll is tightly secured with thick cord, neatly and tautly wound round from end to end. In three weeks or so the leaf is welded into a solid, torpedo-shaped plug, which is cut into small, square slices and rubbed up for the pipe.

This is true navy-cut. But scarcely any of the tobacco sold as such is so prepared, being pressed and cut like ordinary flake tobacco. Originally all tobacco was prepared, like true navy-cut, by hand; in the not remote past each smoker carried his plug of tobacco about with him, and cut it up as the occasion and his pipe demanded.

From a strictly chronological point of view this account of the manufacture of tobacco should have commenced with cake tobacco. The herb smoked by Elizabethan worthies was ‘ pudding,’ ‘ roll,’ and ‘ twist.’ These hard tobaccos are the forms in which ‘ the weed of glorious feature ‘ was originally prepared. They were compact and convenient for carrying about, the smoker slicing off a pipeful as required, and equally suitable for chewing and smoking. The plug known as carotte in the seven- teenth century was a roll, about lo inches long and 3 inches thick, sweetened with treacle. It was for such a roll of Virginia that Sir Roger de Coverley called at a tobacconist’s on his way to Westminster Abbey.

That’s it for this month. I hope you’ve enjoyed your time here, and keep the great questions coming!

-glp

Since 1999, Gregory L. Pease has been the principal alchemist behind the blends of G.L. Pease Artisanal Tobaccos. He’s been a passionate pipeman since his university days, having cut his pipe teeth at the now extinct Drucquer & Sons Tobacconist in Berkeley, California. Greg is also author of The Briar & Leaf Chronicles, a photographer, recovering computer scientist, sometimes chef, and creator of The Epicure’s Asylum. |

As usual, an interesting peek behind the scenes with a first rate tobacconist and well written replies to boot. Keep these articles coming and thanks to Kevin for hosting the column. GLP blends have become a staple in my pipe, keep up the great blending!

Thanks for the follow-up on navy Flake Greg.

And yes, please Mr. Pease, an article devoted to Dark-Fired Kentucky would be great!

Very enjoyable read Mr. GLP

Thank you for your time, knowlegde, and doing all that pesky research for me. ^_^

I love the pesky research, Spartan, so it’s truly my pleasure! And, thanks Al and OTD for your comments!

Great stuff as always. Also…

“I’ve been meaning to write something more in-depth, and if there’s interest, I’ll turn the fires up under that project, so to speak.”

I’ve recently taken a great interest in the dark fired Kentucky, so please consider this my tossing some logs on those fires and fanning really hard!

Back in the ’60’s, as a lover of Players and Capstan Navy Cuts, I thought I’d try the real thing by buying a hemp wrapped canvas roll of “Ships Plug” which my local tobacconist had displayed for a long time. It was horrible! Harsh, strong and flaky.

A bit like ethnic foods – a bit of authenticity can go a long way.

I found an older Codger though who normally smoked Condor Bar and he thought it was the Holy Grail.

No seat at the Round Table for me.

Another great installment, Greg. Regarding dark fired kentucky, how does the smoking curing affect the nicotine content? Also, in addition to “kentucky” we also hear about “carolina” and “maryland” leaf. I live in Georgia, and I know tobacco is grown here. Is there “georgia” leaf? It would be great if you could touch on this in the next installment.

I’ll add my appreciation for the dark-fired Kentucky explication! We’ve been tinkering with the NYPC blends and I’ve recommended adding a bit of it to one based on my enjoyment of both JackKnifes and Triple Play, both of which use it masterfully.

Good article. I live, and have lived for years, in a region of Tennessee where Dark-fired Burley is grown and processed. We were once a large center of tobacco growing and marketing for many years with warehouses scattered throughout the city. I always noted when fire-curing was begun as while driving out in the country you could smell the pleasant aroma of tobacco being cured in barns for miles around. Sadly often you would hear reports of barns burning to the ground and crops being lost from uncontrolled or unwatched fires. Also once the firing/curing was complete and the tobacco was being brought to market, you could hear reports on the local radio stations of the market prices received at the local auctions now gone. Also you could often find “hands” of tobacco on the roads where some had fallen from the trailers hauling tobacco to market. Conwood and US Tobacco both have a presence here and many of our youth spent summer employment measuring tobacco fields for compliance with regulations regarding field sizes and allotments. I guess this is almost all gone now with changes in marketing and government controls.

years ago (45) the first pipe i bought had a wooden bole that screw on to a steelcome stem , the stem was made of three tubes (i asume for cooling) that conecet to the mouth pice it was a great pipe the bottome of the bole unscrew to clean , would you have any idea whare i could find a pipe like this? i bought at local pharmace as that is whare you boght tabaco products back then?

Falcon pipes:

http://www.smokingmetal.co.uk/pipe.php?page=107

Purchaseable from any e-tailer; see who advertises on here.