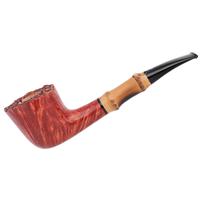

So, I've read many of the backposts and guess I'm convinced I shouldn't plan on restoring stems using a variable speed dremel.

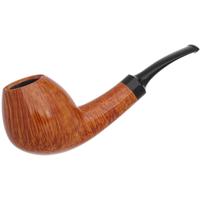

I'm thinking of starting with a couple of pipes doing everything manually, then buying a 1750 speed buffer.

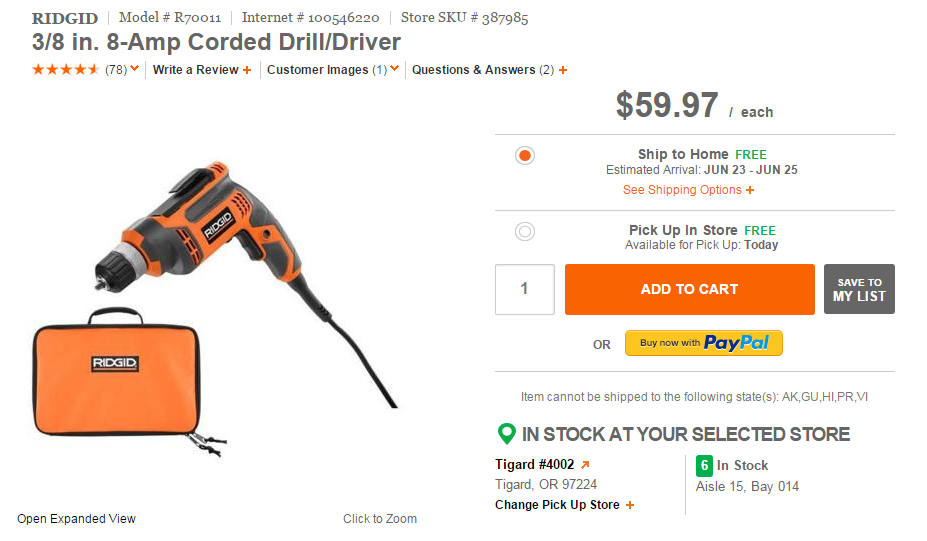

I looked on Amazon and the closest buffer was 10" at 1725 RPM - right around $300.

Where might I find a deal on a used one - or is ebay it?

Thanks.

I'm thinking of starting with a couple of pipes doing everything manually, then buying a 1750 speed buffer.

I looked on Amazon and the closest buffer was 10" at 1725 RPM - right around $300.

Where might I find a deal on a used one - or is ebay it?

Thanks.