Years ago, when I owned and operated a pipe shop, I offered a pipe cleaning and restoration service to my customers. I had some guys bring in dozens of pipes at a time for me to overhaul and many had been neglected to the point that they were unsmokable. Some had so much cake that there wasn't any room for tobacco.

It didn't take me long to realize that reaming a large number of pipes with a hand reamer can get tiring and that I needed a better way, so I developed one. Now that I'm retired I still use the same procedure on my own pipes. It's especailly good because I tend to let the pipe reaming wait till I have a quite a few, then I take about 50 pipes out to my workshop and do them all at once. If I tried to ream that many at one time by hand I would end up with a sore arm.

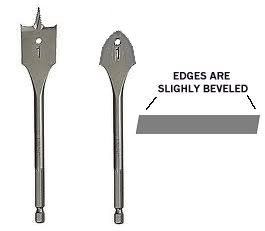

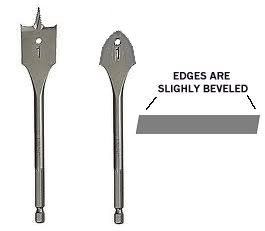

How I do it is this. I have taken several carpenter's spade bits and modified them for pipe reaming. I used my bench grinder to reshape the head of the bits to fit different pipe bowl shapes. I found that the four different ones I have will do all my pipes.

To ream a pipe I install the appropriate shape bit in my drill press and then, holding the pipe by hand (stem removed), I let the press to the work while I just hold the pipe. It works great and I've never damaged a pipe.

Here are some things to know if you're interested in makeing a setup like this for yourself.

In shapeing your bits the biggest challenge in to get the 2 side to be mirror images each other. In other words, you want them to be the same angle so the bit is balanced. As you are shaping it you can stop every now and then chuck it up in the drill press an by rotating it at high speed and using chalk or something similar you can check for unevenness. It just takes a little practice and patience. If it's not absolutely perfect it will still work. Close is good enough and the only difference is you will notice a slight vibration when reaming.

You should put a slight bevel on the cutting edges of your drill bits, Angle the edge slightly so that the sharp part is the leading edge when reaming. I use the work "sharp" for lack of a better one. You don't want it "too" sharp. If you think you could cut yourself with it then it's way to sharp. What you want is an edge that will scrape not cut. And make sure the pointed end of the bit is not sharp, round it off a little.

When reaming your pipes do so at low speed. I have mine set up so it turns at about 100 rpm. This will allow you to easily control the pipe by hand and will help keep you from damageing the pipe. Too high a speed would cause you to "overream" the pipe or loose control. Also this low speed it the reason that your hand made bit doesn't have to be absolutely perfect in shape... Remember, this is pipe reaming, not watch making.

If you don't have a drill press you can use a hand drill. It needs to be one with veriable speed so you can go slow. A frined of mine uses his rechargable drill and rests the base of the drill, which is a big, flat bottomed battery, on his work bench. It works great.

If you are interested in this and have any questions please feel free to post them here and I'll do my best to answer them. Now, get reamed...

Image: Left is carpenter's spade bit. Right is after it has been made into a pipe reamer.

It didn't take me long to realize that reaming a large number of pipes with a hand reamer can get tiring and that I needed a better way, so I developed one. Now that I'm retired I still use the same procedure on my own pipes. It's especailly good because I tend to let the pipe reaming wait till I have a quite a few, then I take about 50 pipes out to my workshop and do them all at once. If I tried to ream that many at one time by hand I would end up with a sore arm.

How I do it is this. I have taken several carpenter's spade bits and modified them for pipe reaming. I used my bench grinder to reshape the head of the bits to fit different pipe bowl shapes. I found that the four different ones I have will do all my pipes.

To ream a pipe I install the appropriate shape bit in my drill press and then, holding the pipe by hand (stem removed), I let the press to the work while I just hold the pipe. It works great and I've never damaged a pipe.

Here are some things to know if you're interested in makeing a setup like this for yourself.

In shapeing your bits the biggest challenge in to get the 2 side to be mirror images each other. In other words, you want them to be the same angle so the bit is balanced. As you are shaping it you can stop every now and then chuck it up in the drill press an by rotating it at high speed and using chalk or something similar you can check for unevenness. It just takes a little practice and patience. If it's not absolutely perfect it will still work. Close is good enough and the only difference is you will notice a slight vibration when reaming.

You should put a slight bevel on the cutting edges of your drill bits, Angle the edge slightly so that the sharp part is the leading edge when reaming. I use the work "sharp" for lack of a better one. You don't want it "too" sharp. If you think you could cut yourself with it then it's way to sharp. What you want is an edge that will scrape not cut. And make sure the pointed end of the bit is not sharp, round it off a little.

When reaming your pipes do so at low speed. I have mine set up so it turns at about 100 rpm. This will allow you to easily control the pipe by hand and will help keep you from damageing the pipe. Too high a speed would cause you to "overream" the pipe or loose control. Also this low speed it the reason that your hand made bit doesn't have to be absolutely perfect in shape... Remember, this is pipe reaming, not watch making.

If you don't have a drill press you can use a hand drill. It needs to be one with veriable speed so you can go slow. A frined of mine uses his rechargable drill and rests the base of the drill, which is a big, flat bottomed battery, on his work bench. It works great.

If you are interested in this and have any questions please feel free to post them here and I'll do my best to answer them. Now, get reamed...

Image: Left is carpenter's spade bit. Right is after it has been made into a pipe reamer.