Oom Paul Question

- Thread starter irishearl

- Start date

SmokingPipes.com Updates

Watch for Updates Twice a Week

- Status

- Not open for further replies.

To some degree, yes, as the chamber on Hungarians (aka Oom Paul) tends to be deeper than on other pipes. The solution is to dry the tobacco more prior to loading.

I have a Savinelli Hercules (large bowl, no filter series) Oom'Paul, and I have never had a gurgle. I think it is probably well designed, but it may also help that it is an ideal smoker for Tabac-Manil Semois which is a very dry burley variant cut. Perhaps a very moist blend would cause the occasional gurgle.

Pipes with curving and bending airways induce condensation of the moisture in the smoke stream. About the only thing you can do about it is use drier tobacco, don't light-up too aggressively, and smoke in a environment that has less humidity.

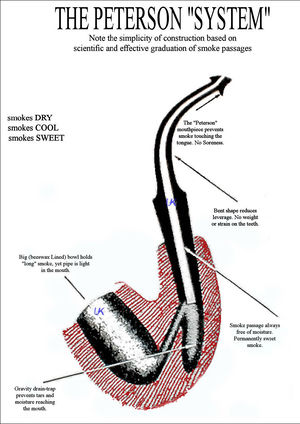

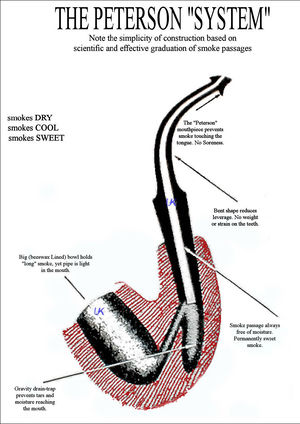

It is a notorious and age-old problem, and one that prompted Peterson to develop their "system" pipes -- designed to intentionally move the smoke stream circuitously and deposit the condensate in a sump well. It would appear that they are a real PITA to clean.

For more info on the system pipe, see: https://pipedia.org/wiki/A_closer_look_at_the_famous_Peterson_Standard_System_Pipe

It is a notorious and age-old problem, and one that prompted Peterson to develop their "system" pipes -- designed to intentionally move the smoke stream circuitously and deposit the condensate in a sump well. It would appear that they are a real PITA to clean.

For more info on the system pipe, see: https://pipedia.org/wiki/A_closer_look_at_the_famous_Peterson_Standard_System_Pipe

I had a Wally Frank Oom Paul several years ago, and it was a great pipe. It did smoke wet though, so I would just run a pipe cleaner through it when I notice excess moisture building up in the pipe. It never gurgled, but it did collect a lot of moisture which is going to happen with that style of pipe. I don't have the pipe anymore as I sold it. I miss that pipe now.

I have a Barling Manx meerschaum Oom Paul pipe, and it smokes comparatively dry. Perhaps such a pipe might be an option for you.

A better term is "Hungarian". Paul Kruger was a son of a bitch, and while he smoked a pipe, no one has ever produced a photo of him smoking the Hungarian shape. Why someone started calling that shape "Uncle Paul" is odd. An undeserved encomium.

I have a number of them, not inherently wet. I have a weber oom paul with a jobey link tenon. I ended up opening up the jobey link with a drill bit but not because it was a wet smoker.

Most factory-made Oom Pauls have some kind of interference between the tenon and the airway, due to the angles required for drilling. They are tricky to make well.

So inherently, an Oom Paul is not a worse/wetter pipe than any other, if it's made well, but this takes serious skill and care, and most pipes just don't get that.

I have a Castello 98 shape and it's a great smoker, passes a cleaner even.

So inherently, an Oom Paul is not a worse/wetter pipe than any other, if it's made well, but this takes serious skill and care, and most pipes just don't get that.

I have a Castello 98 shape and it's a great smoker, passes a cleaner even.

I just bought an oom paul from joeman on here. It's a no name, small, 1.4oz oom paul. I was looking for a lightweight clencher, and this is exactly what I was going for. I can already say it's one of my best smokers. Beats out many of the brand names I own.

Oh, and it doesn't smoke wet. Probably because of the smaller chamber size (which is really about medium sized when compared with other pipes of mine but small in comparison to the typical oom paul shape).

So, what I said above is bullshit?inherently, an Oom Paul is not a worse/wetter pipe than any other, if it's made well

Wouldn't physics dictate that the Oom Paul is ideally designed for gravity to do it's dirty work of pulling moisture back down the airway? I've never smoked an Oom Paul, but have always assumed they are a gurgle monster.

EDIT: I have smoked deeply bent pipes, just never a true Oom Paul shape.

EDIT: I have smoked deeply bent pipes, just never a true Oom Paul shape.

Cortez, I'm not sure why you think that I would have any issue with what you said. I'll quote you and I'll quote me.

You: Pipes with curving and bending airways induce condensation of the moisture in the smoke stream.

Me: interference between the tenon and the airway, due to the angles required for drilling. They are tricky to make well.

The geometry of the pipe is difficult.

There are any number of solutions to the problem - the Peterson system is one - induce the condensation and catch it. Castello, for example, does not do this, they drill the pipe with tremendous care and try to line things up so there isn't condensation. But most of the Ooms I've owned, Savinelli for example, take no such care, and the pipes smoke wet due to condensation issues caused by ugly construction.

I make Oom Pauls all the time, I love the shape. And I make the mortise wide and shallow, and this allows me to drill it just about dead center. I expect my Oom Pauls to smoke absolutely no different than any other pipe.

You: Pipes with curving and bending airways induce condensation of the moisture in the smoke stream.

Me: interference between the tenon and the airway, due to the angles required for drilling. They are tricky to make well.

The geometry of the pipe is difficult.

There are any number of solutions to the problem - the Peterson system is one - induce the condensation and catch it. Castello, for example, does not do this, they drill the pipe with tremendous care and try to line things up so there isn't condensation. But most of the Ooms I've owned, Savinelli for example, take no such care, and the pipes smoke wet due to condensation issues caused by ugly construction.

I make Oom Pauls all the time, I love the shape. And I make the mortise wide and shallow, and this allows me to drill it just about dead center. I expect my Oom Pauls to smoke absolutely no different than any other pipe.

Here's a quickie diagram etched over the last Oom Paul er, Hungarian, I made.

First, a typical mortise, 5/16" maybe, and 3/4" deep (or more, lots of these pipes have a well in the shank). You can see where the airway is likely to terminate on the wall of the mortise because of the angles required. In fact I had a Chacom like this - 1/4" tenon, and it completely occluded the airway when the pipe was assembled - you couldn't draw smoke.

If a guy makes a few adjustments to mortise width and depth, suddenly the pipe can be drilled "bang on".

This is maybe exaggerated a little for the purposes of exposition, but there's the basic physical problem of an Oom Paul - if you do it without care, you get a nasty smoker pretty easy, whereas a straighter pipe you just don't have these kinds of issues.

First, a typical mortise, 5/16" maybe, and 3/4" deep (or more, lots of these pipes have a well in the shank). You can see where the airway is likely to terminate on the wall of the mortise because of the angles required. In fact I had a Chacom like this - 1/4" tenon, and it completely occluded the airway when the pipe was assembled - you couldn't draw smoke.

If a guy makes a few adjustments to mortise width and depth, suddenly the pipe can be drilled "bang on".

This is maybe exaggerated a little for the purposes of exposition, but there's the basic physical problem of an Oom Paul - if you do it without care, you get a nasty smoker pretty easy, whereas a straighter pipe you just don't have these kinds of issues.

I have a Castello shape #97 oom paul that smokes like a dream............ never a gurgle, but I don't smoke it too much nowadays.

Squatch- are you sure yours is a #98? I've not seen that shape, and wonder what the difference is from a #97?

Squatch- are you sure yours is a #98? I've not seen that shape, and wonder what the difference is from a #97?

- Status

- Not open for further replies.