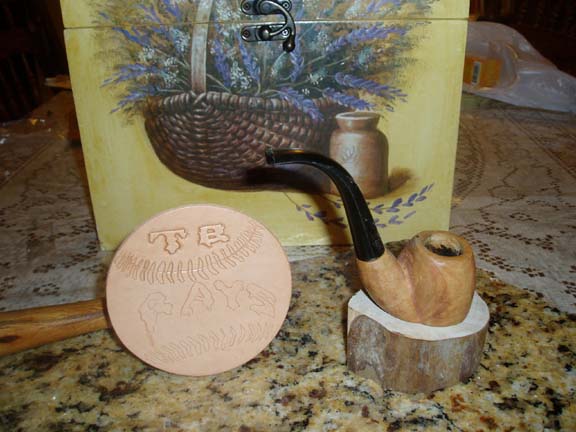

One of pipes I made

- Thread starter hobojoe

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingPipes.com Updates

Watch for Updates Twice a Week

- Status

- Not open for further replies.

+1 on the natural finish. Looks sharp.

There was a time when I felt a pipe left natural wasn't finished and looked wrong.

Then I bought a Nording Signature that was natural and watched it color over time.

Now they seem perfectly normal.

Good looking pipe, Joe.

There was a time when I felt a pipe left natural wasn't finished and looked wrong.

Then I bought a Nording Signature that was natural and watched it color over time.

Now they seem perfectly normal.

Good looking pipe, Joe.

Looks great! I too like the look and feel of a pipe with no finish on it, and the shape on this one is great, its hard to beat a sitter.

Very nice - sitters don't often appeal to me, but you've done serious justice there. I too am somewhat curious as to how pecan wood affects the flavour of the smoke; I've got a rock-maple pipe that imparts a sweet flavour...or, at least, it did until it got cake.

Thanks for all the complements. I used Lanes 1Q and the sweet tobacco

overwhelmed the wood. I started making pipes this year. Using 4 inch

belt and 1 inch band sander. Dremel with flex shaft and sandpaper.

One of the problems is the shape i start out to do changes during

work on wood. It seems that Evan using a square and straight edge.

nothing ends up straight. so its by eye sight only.

Joe

overwhelmed the wood. I started making pipes this year. Using 4 inch

belt and 1 inch band sander. Dremel with flex shaft and sandpaper.

One of the problems is the shape i start out to do changes during

work on wood. It seems that Evan using a square and straight edge.

nothing ends up straight. so its by eye sight only.

Joe

While making pipes can be very satisfying, especially when you get to smoke one of your own pipes, shaping by eye can be at the least, a hard venture.

Getting everything even using that method takes a lot of practice and even then can be difficult for a new guy.

Keep up the great work and I'll keep watching as you progress, as I love watching the progression of a budding pipe maker.

A couple tips........ work a bit more on your shank to stem fit, as a cleaner and smoother fit and look there is preferred. You may also want to clean up the stem a bit more also with some sand paper. I start with about 400 grit and work my way up finishing with 1000 grit wet/dry and sand using it with water. Gives a very smooth look before finally finishing with a buffing wheel and white diamond buffing compound.

Getting everything even using that method takes a lot of practice and even then can be difficult for a new guy.

Keep up the great work and I'll keep watching as you progress, as I love watching the progression of a budding pipe maker.

A couple tips........ work a bit more on your shank to stem fit, as a cleaner and smoother fit and look there is preferred. You may also want to clean up the stem a bit more also with some sand paper. I start with about 400 grit and work my way up finishing with 1000 grit wet/dry and sand using it with water. Gives a very smooth look before finally finishing with a buffing wheel and white diamond buffing compound.

I do as much of the shaping and drilling on my pipes on the lathe . It really helps get things even and flowing right. From there I use the pad for a disk sander mounted in a Jacobs chuck in the lathe for shaping. The velcro discs make life so much easier.

To answer the questions around 20 hours to make. I do have a lathe but its a cheap one

and I never used one before. Stems are a problem. The ones i buy

seam to have a contour where the tenon meets the main part of the

stem. Not a Flush face. Ordered from 2 different places. 1 is inexpensive and the

other expensive $8.00.

As far as making one as good as I have seen ? Well I know what reality is.

Joe

and I never used one before. Stems are a problem. The ones i buy

seam to have a contour where the tenon meets the main part of the

stem. Not a Flush face. Ordered from 2 different places. 1 is inexpensive and the

other expensive $8.00.

As far as making one as good as I have seen ? Well I know what reality is.

Joe

Joe,I had the same problems with stems. Most molded stems you buy will need some work.either the tenon turned down or facing for a flush fit or usually -both.There are tenon cutters out there ranging from $50-60 up $2-300.00. I found one that you can buy at any Sears or auto part store or even a garage sale--if you don't have one in your toolbox already-- for probably $8 to $10

It's just a short 1/2" drive socket extension. Chuck it up,stick the button end in the extension,bring the tailstock and live center up against the tenon tight enough so there is no back and forth movement . I even used this to work a churchwarden stem. had to wrap masking tape around the button end because it is narrow.

It's just a short 1/2" drive socket extension. Chuck it up,stick the button end in the extension,bring the tailstock and live center up against the tenon tight enough so there is no back and forth movement . I even used this to work a churchwarden stem. had to wrap masking tape around the button end because it is narrow.

http://pipesmagazine.com/members/ejames/album

http://pipesmagazine.com/members/ejames/album

- Status

- Not open for further replies.