I’ve been buying Missouri Meerschaum pipes now for nearly fifty years, and while they are truly the World’s Finest Corn Cob pipe, unlike a genuine Star Grade Lee briar pipe, the corn cobs used are by comparison, soft and prone to damage, that a Lee Star Grade would shrug off.

Almost 25 years ago I had the honor and privilege of spending a couple of hours inside the Missouri Meerschaum factory at Washington, Missouri. The manufacture of these pipes is fascinating, and they are not machine made, they are all hand made by Missourians using machines. Plaster of Paris and ordinary glue is used extensively, on special hybrid cobs raised locally and dried for about two years.

I bought this huge Freehand model during that visit, and a quarter century of use has resulted in the top of the bowl starting to separate.

I took ordinary Elmer’s Carpenter’s Glue, and applied three different applications last night, rubbed in the glue, heated it with a lighter, and this morning my MM Freehand looks a lot better.

Glue also works to seal up leaky cob pipes if they develop a leak around the shank to bowl.

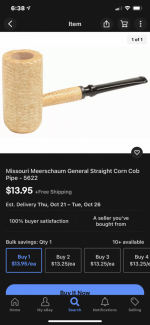

I ordered a new Freehand last night for $35 just as close to my old one as they still make. These pipes were $25 at the factory in the late 1990s.

I ordered a new Freehand last night for $35 just as close to my old one as they still make. These pipes were $25 at the factory in the late 1990s.

The models that are smooth polished are made using plaster of Paris to reinforce and strengthen the cob, which was an early patented process of MM.

The models that are smooth polished are made using plaster of Paris to reinforce and strengthen the cob, which was an early patented process of MM.

The seal between hardwood shank and cob is made using ordinary white glue at the factory. If they ever leak, get out the Elmer’s glue and go to work.

But whether it’s a $5 Washington or $35 Freehand, all MM pipes are made from the same cobs, by the same careful methods, on the same machines, in the same factory as they have been for almost a century and a half.

But whether it’s a $5 Washington or $35 Freehand, all MM pipes are made from the same cobs, by the same careful methods, on the same machines, in the same factory as they have been for almost a century and a half.

If ever in the middle of Missouri don’t miss visiting the Missouri Meerschaum pipe factory.

They stopped factory tours about twenty years ago, when they put up a fascinating museum in the lower floor of the factory.

They still have their factory shop and an employee will answer any questions you might have about the pipes.

Almost 25 years ago I had the honor and privilege of spending a couple of hours inside the Missouri Meerschaum factory at Washington, Missouri. The manufacture of these pipes is fascinating, and they are not machine made, they are all hand made by Missourians using machines. Plaster of Paris and ordinary glue is used extensively, on special hybrid cobs raised locally and dried for about two years.

I bought this huge Freehand model during that visit, and a quarter century of use has resulted in the top of the bowl starting to separate.

I took ordinary Elmer’s Carpenter’s Glue, and applied three different applications last night, rubbed in the glue, heated it with a lighter, and this morning my MM Freehand looks a lot better.

Glue also works to seal up leaky cob pipes if they develop a leak around the shank to bowl.

I ordered a new Freehand last night for $35 just as close to my old one as they still make. These pipes were $25 at the factory in the late 1990s.

I ordered a new Freehand last night for $35 just as close to my old one as they still make. These pipes were $25 at the factory in the late 1990s. The models that are smooth polished are made using plaster of Paris to reinforce and strengthen the cob, which was an early patented process of MM.

The models that are smooth polished are made using plaster of Paris to reinforce and strengthen the cob, which was an early patented process of MM.The seal between hardwood shank and cob is made using ordinary white glue at the factory. If they ever leak, get out the Elmer’s glue and go to work.

But whether it’s a $5 Washington or $35 Freehand, all MM pipes are made from the same cobs, by the same careful methods, on the same machines, in the same factory as they have been for almost a century and a half.

But whether it’s a $5 Washington or $35 Freehand, all MM pipes are made from the same cobs, by the same careful methods, on the same machines, in the same factory as they have been for almost a century and a half.If ever in the middle of Missouri don’t miss visiting the Missouri Meerschaum pipe factory.

They stopped factory tours about twenty years ago, when they put up a fascinating museum in the lower floor of the factory.

They still have their factory shop and an employee will answer any questions you might have about the pipes.