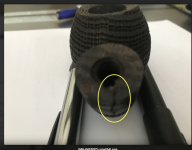

I have a Morta pipe that has developed a couple of cracks in the mortise. The first crack extends ~1/2" externally on the backside of the pipe, starting where the stem seats propagating downward towards the bowl. It also appears that the crack extends into the mortise through to the draft hole. A second crack appears along a different grain line and below (towards the bowl) the first crack, it's ~1/4" long. The pictures are the best I can get with my phone.

The company has replaced this pipe with a new one. Don't know much about Morta but it seems like this one could be salvaged, perhaps with a band?

The company has replaced this pipe with a new one. Don't know much about Morta but it seems like this one could be salvaged, perhaps with a band?

![IMG-0451[28] copy[95].png](/forums/data/attachments/101/101149-d662c07e96b4c6fb75aa48de6ac39f02.jpg)

![IMG-0453[97] copy[54].png](/forums/data/attachments/101/101150-8650b057668f675ae6bc3da9ea781390.jpg)