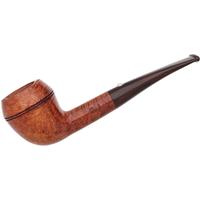

So I took a chance on a cheap Briarcraft BriarMeer on eBay. description was they weren’t sure about liner but thought it was gone.

Well, it’s gone. Thinking of just using it as a big pot-there isn’t residue of glue in bowl. I don’t see any defects

I’m currently taking crappy stain off, topping bowl, and have fixed stem being overclocked.

Before I bother doing stem repair and clean up I wanted to ask those more experienced than myself:

How thick do chamber walls need to be? Walls are right at 5/16”…

Well, it’s gone. Thinking of just using it as a big pot-there isn’t residue of glue in bowl. I don’t see any defects

I’m currently taking crappy stain off, topping bowl, and have fixed stem being overclocked.

Before I bother doing stem repair and clean up I wanted to ask those more experienced than myself:

How thick do chamber walls need to be? Walls are right at 5/16”…