Hey Folks,

I joined this forum a few weeks ago when I posted some before and after pics of a yellow Dr. Grabow Viscount on the "What's under that Grabow" thread... http://pipesmagazine.com/forums/topic/whats-under-that-grabow/page/2

A couple folks asked for more info on how I restore these pipes, so I thought I'd start a thread on it. First I will say that I am not a professional at this. Just a hobbyist that loves saving these old color series pipes. I love finding ones in pristine condition too, but I especially love taking really bad ones refurbishing them.

The first thing I do is give the outside of the pipe a good thorough cleaning. Sometimes pipes that look really bad actually clean up nicely and do not need refinishing at all. I have been surprised by that. I start with a sponge and some dish detergent. That usually gives a pretty good indication if the pipe is going to need to just be cleaned up or refinished. If it is still dirty but free from cracks and chips I will get a little more aggressive and use a magic eraser with a very light touch. That will typically remove the wax and you will know for sure what you are dealing with at that point. Even though the pipe I chose for this project looked pretty obviously in need of a refinishing, I stilled went through that cleaning process first. I always start as gently as possible and go from there.

Here are pics of it after being cleaned. You can see there are quite a few chips in the paint:

But worse than that, there was some sort of glue or something on a good portion of the bowl. This would not come off:

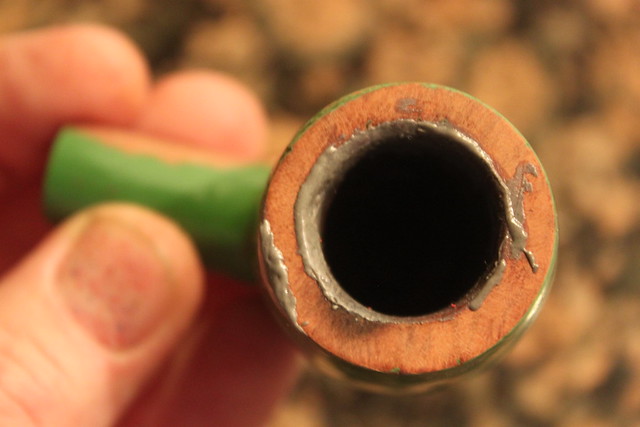

But worst of all was the condition of the rim. It had obviously been beat on a knocker. Why?...

So yes, in my opinion this pipe is a perfect candidate for a full-on restoration with a refinish. The next step will be to ream the bowl, and clean and sanitize the bowl and shank. Once that is done I will begin with repairs to the rim.

I joined this forum a few weeks ago when I posted some before and after pics of a yellow Dr. Grabow Viscount on the "What's under that Grabow" thread... http://pipesmagazine.com/forums/topic/whats-under-that-grabow/page/2

A couple folks asked for more info on how I restore these pipes, so I thought I'd start a thread on it. First I will say that I am not a professional at this. Just a hobbyist that loves saving these old color series pipes. I love finding ones in pristine condition too, but I especially love taking really bad ones refurbishing them.

The first thing I do is give the outside of the pipe a good thorough cleaning. Sometimes pipes that look really bad actually clean up nicely and do not need refinishing at all. I have been surprised by that. I start with a sponge and some dish detergent. That usually gives a pretty good indication if the pipe is going to need to just be cleaned up or refinished. If it is still dirty but free from cracks and chips I will get a little more aggressive and use a magic eraser with a very light touch. That will typically remove the wax and you will know for sure what you are dealing with at that point. Even though the pipe I chose for this project looked pretty obviously in need of a refinishing, I stilled went through that cleaning process first. I always start as gently as possible and go from there.

Here are pics of it after being cleaned. You can see there are quite a few chips in the paint:

But worse than that, there was some sort of glue or something on a good portion of the bowl. This would not come off:

But worst of all was the condition of the rim. It had obviously been beat on a knocker. Why?...

So yes, in my opinion this pipe is a perfect candidate for a full-on restoration with a refinish. The next step will be to ream the bowl, and clean and sanitize the bowl and shank. Once that is done I will begin with repairs to the rim.