Vintage Plug Cutter

An old Store plug cutter for sale. Its on an auction site, but some of you guys may be interested in it for a collection.

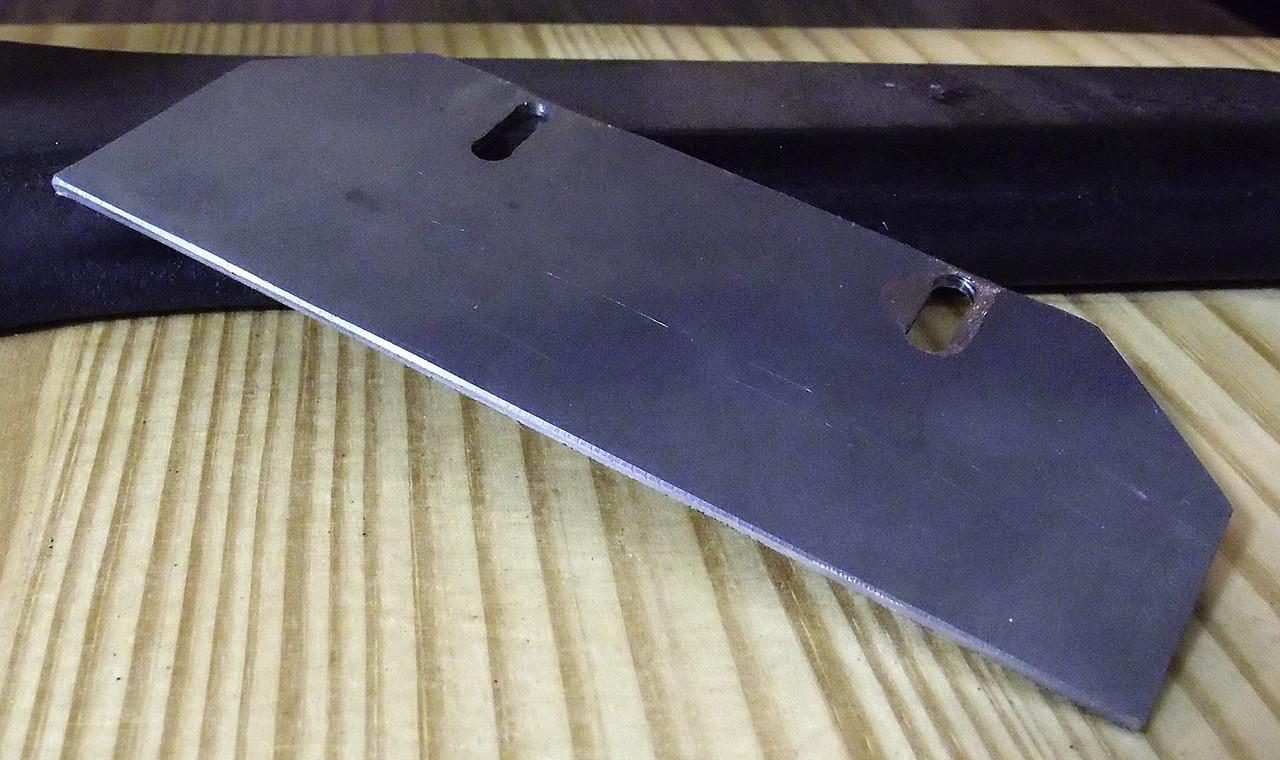

A vintage cast iron tobacco cutter by P. Lorillard & Company. Cutters such as this rested on the counters of general stores for used by patrons to cut plug chewing tobacco for sale by the inch, or half inch. It features a long base with a semi-circle frame encompassing a blade that drops when a lever is pressed down, and two mounting holes for fastening to a counter or table top. The name “P. Lorillard & Co.” is embossed into the frame and base.

I have no affiliation with the site or the seller, just thought it was cool and wanted to share it with the board.

An old Store plug cutter for sale. Its on an auction site, but some of you guys may be interested in it for a collection.

A vintage cast iron tobacco cutter by P. Lorillard & Company. Cutters such as this rested on the counters of general stores for used by patrons to cut plug chewing tobacco for sale by the inch, or half inch. It features a long base with a semi-circle frame encompassing a blade that drops when a lever is pressed down, and two mounting holes for fastening to a counter or table top. The name “P. Lorillard & Co.” is embossed into the frame and base.

I have no affiliation with the site or the seller, just thought it was cool and wanted to share it with the board.