There are Dunhill collectors, Dunhill ODA collectors, and Dunhill ODA's-of-a-specific-shape collectors.

The last sort are definitely lifers, because there aren't many ODA's in the world to begin with, and finding a specimen of every finish within a specific shape number isn't easy. To find a full set of one the scarcest shapes in the ODA range borders on masochistic.

The pipe in this thread was sent to me by one of those guys. :lol: (If he were an athlete he'd want to run the Leadville 100 or climb Mount Everest, I imagine.)

How rarity collectors tend to do it is by filling their collection with whatever they can find, and then never stop playing King of the Hill, swapping out weak specimens when stronger ones are found.

Dunhill's 838 in the Root finish is a right little piggy in that regard, though, being infamously elusive. Never mind trading up, finding one for sale in pretty much any condition is a rare enough event that you grab first and deal with its issues later.

And here we are. This one had a poorly-made replacement stem (even the dot wasn't round... how's that even possible?!), and the rim had been rounded over at some point with sandpaper and refinished, presumably to remove knock damage. The nomenclature had also suffered from the heavy-handed re-stem (some shaving to achieve level had taken place) and possibly from the rounded rim re-finish (if the entire stummel had been sanded to make the stain color matching easier.)

So, the two main issues with this piece just happened to be what are (by a considerable margin) to two most challenging things to achieve in the pipe repair world: Cutting and leveling a geometric/faceted stem with absolutely ZERO shank manipulation allowed because of the faint nomenclature; and getting a perfect color & translucency match of raw wood to an existing finish when ONLY the raw wood can be touched. (If an entire stummel can be re-stained, even slightly, matching is much easier. That's how it's usually done. But not in this case. Simply color-buffing the shank would blitz the nomenclature.)

Anyway, there you have it, and here are the pics. (My apologies in advance to anyone using a slow connection).

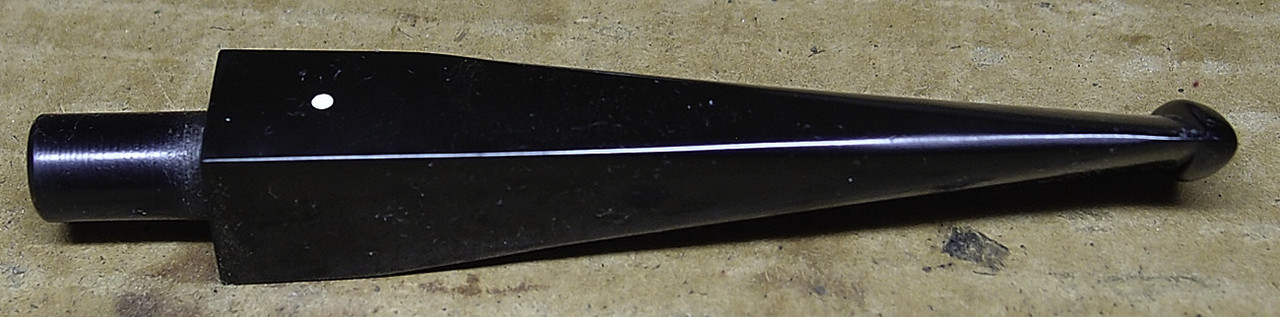

The Patient:

.

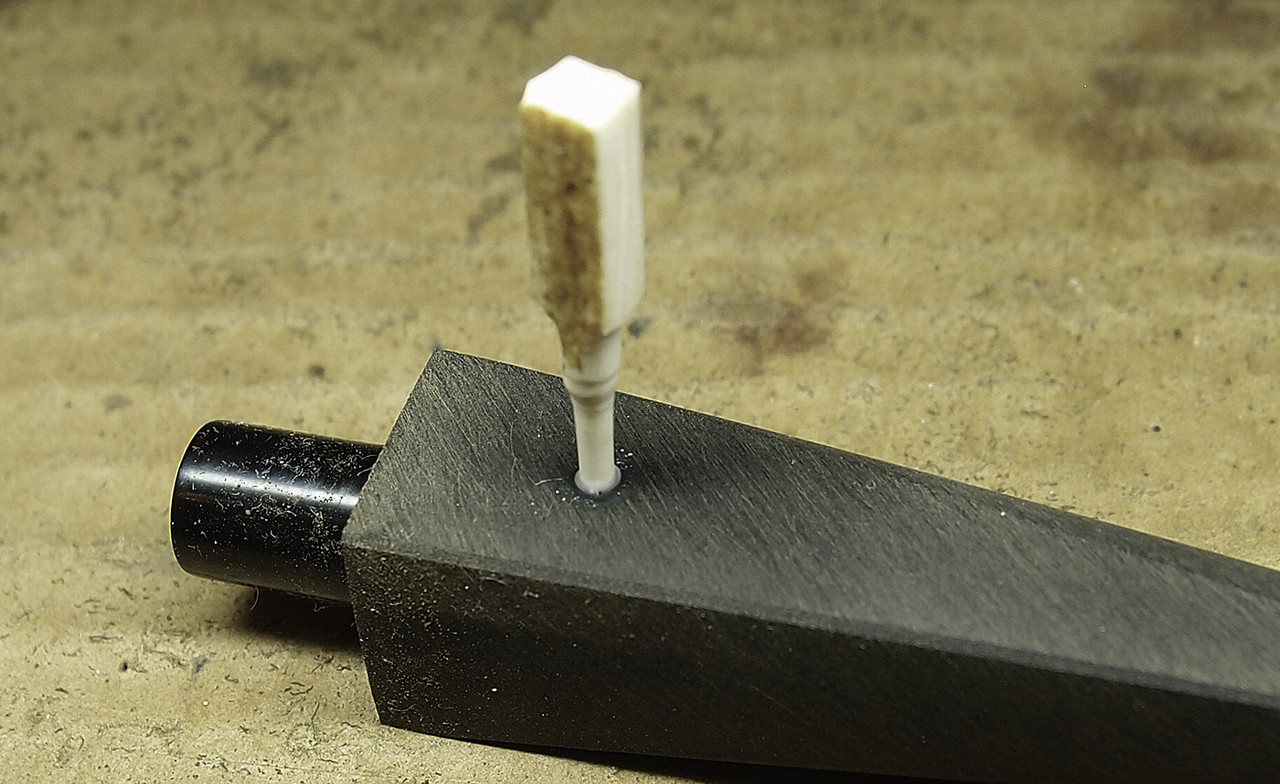

The Process:

.

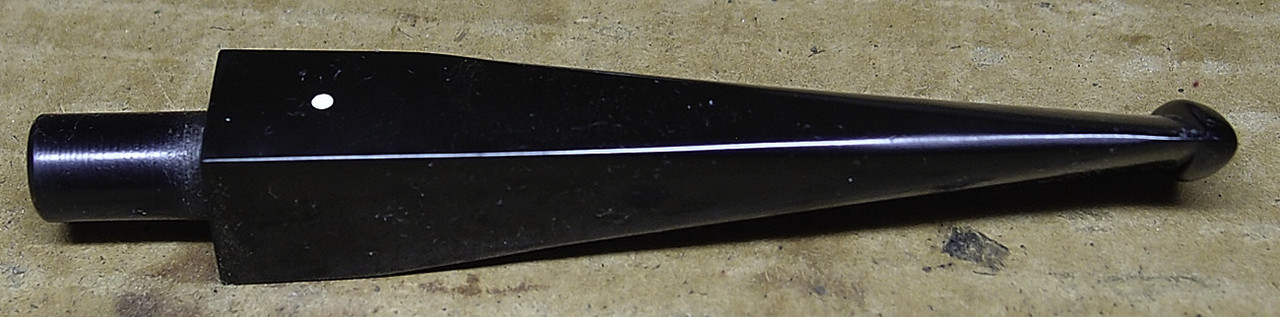

The Result:

The last sort are definitely lifers, because there aren't many ODA's in the world to begin with, and finding a specimen of every finish within a specific shape number isn't easy. To find a full set of one the scarcest shapes in the ODA range borders on masochistic.

The pipe in this thread was sent to me by one of those guys. :lol: (If he were an athlete he'd want to run the Leadville 100 or climb Mount Everest, I imagine.)

How rarity collectors tend to do it is by filling their collection with whatever they can find, and then never stop playing King of the Hill, swapping out weak specimens when stronger ones are found.

Dunhill's 838 in the Root finish is a right little piggy in that regard, though, being infamously elusive. Never mind trading up, finding one for sale in pretty much any condition is a rare enough event that you grab first and deal with its issues later.

And here we are. This one had a poorly-made replacement stem (even the dot wasn't round... how's that even possible?!), and the rim had been rounded over at some point with sandpaper and refinished, presumably to remove knock damage. The nomenclature had also suffered from the heavy-handed re-stem (some shaving to achieve level had taken place) and possibly from the rounded rim re-finish (if the entire stummel had been sanded to make the stain color matching easier.)

So, the two main issues with this piece just happened to be what are (by a considerable margin) to two most challenging things to achieve in the pipe repair world: Cutting and leveling a geometric/faceted stem with absolutely ZERO shank manipulation allowed because of the faint nomenclature; and getting a perfect color & translucency match of raw wood to an existing finish when ONLY the raw wood can be touched. (If an entire stummel can be re-stained, even slightly, matching is much easier. That's how it's usually done. But not in this case. Simply color-buffing the shank would blitz the nomenclature.)

Anyway, there you have it, and here are the pics. (My apologies in advance to anyone using a slow connection).

The Patient:

.

The Process:

.

The Result:

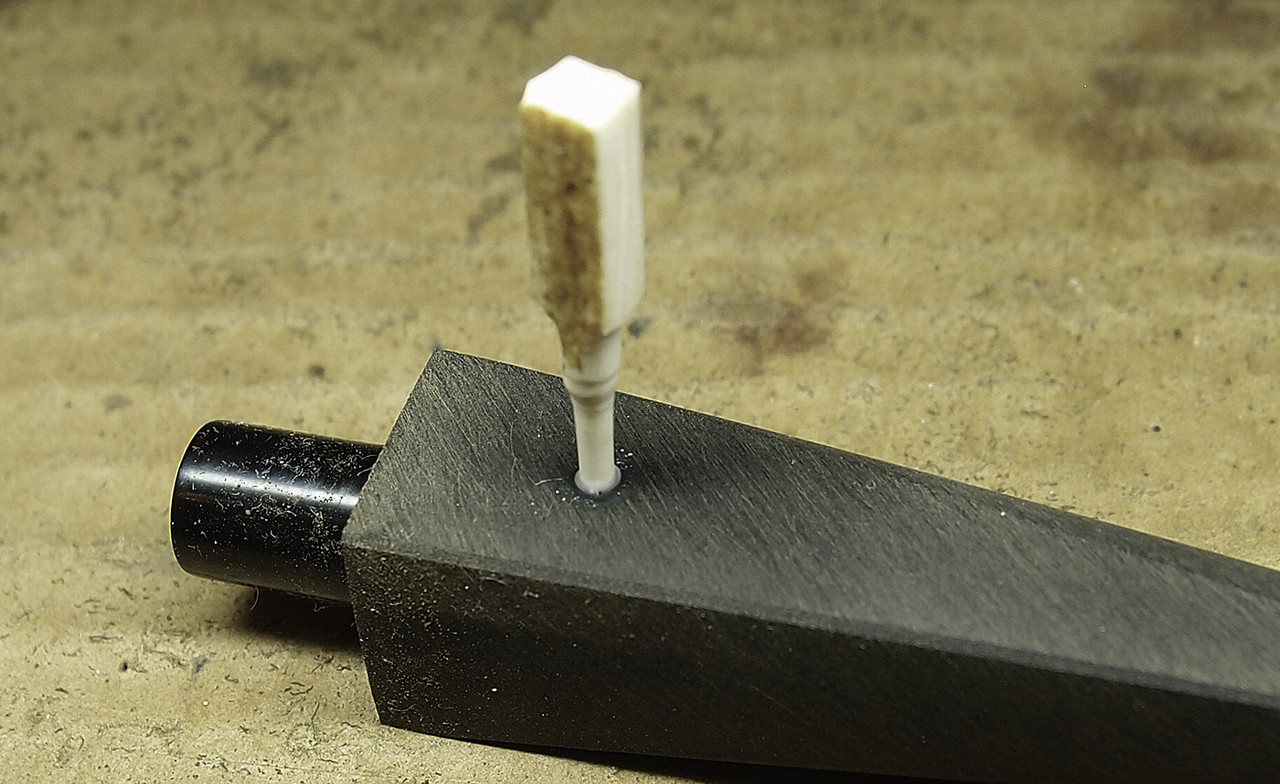

:

: