Being new to this forum, I have no idea if these questions were already addressed in the past. I tried to do a forum search, but came up with nothing, or at best, threads, with deleted photos, which makes these past threads IMO...totally useless. Aplogies for any redundancies.

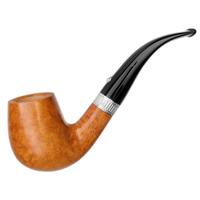

So, I'll ask. Within the sketching process of drawing and designing a pipe profile, the designer needs to figure out how deep the tobacco chamber will need to be drilled and where, and also needs to predict and lay out smoke hole depth and locations in relation to the tenon/mortise joint within the shank. I get, and understand, I think, this step in the design process....but I am very confused when it comes to the actual drilling of draft/smoke holes in sharply bent pipes, or pipes having curved shanks like, for example a Danish-style free-hand. Accuracy when drilling is needed here, or, the pipe goes into the trash bin. Expensive mistakes and plenty of cuss words are the result.

It seems, (under ideal conditions), reasonable to assume that drills can cut only a straight hole, and to a predictable depth. Drills can't be made to generate a curved hole that can follow the center-line and match the curve of a pipe's shank. A steel drill isn't flexible. When making a pipe, the path of the drilled draft-hole will come dangerously close to a shank's top-walls when drilled to intersect with the bottom of a smoke-hole. Envision the tobacco/draft holes in a full-bent pipe.

I understand -from watching at all the badly made, You-tube videos- HOW smoke-holes are drilled but I cannot find one video that explains how to design, predict, and plot the path of the drilled holes that are needed to make a bent pipe having a correctly centered draft hole that intersects perfectly with the bottom of a tobacco chamber.

Does anyone even understand what I'm trying to ask? I'm so confused! I'm not even sure how to ask my questions, it's so complicated. Trust me....I know my way around a wood and metal shop. I've been drilling holes in wood/metal for over 55 years....and yet, I still cannot generate a drilled hole that will follow a curved path as it moves down the center-line of a curved section of wood or metal....like on the shank of a bent/curved pipe. Curved, one-piece shanks, especially, have to be a PITA to drill correctly.

Get my head straightened out, please. Are there methods for drilling curved holes? Flexible drills? Drilling techniques for generating curving holes? I need some schooling.

Frank

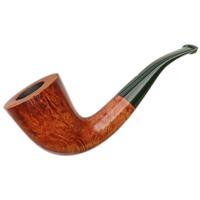

So, I'll ask. Within the sketching process of drawing and designing a pipe profile, the designer needs to figure out how deep the tobacco chamber will need to be drilled and where, and also needs to predict and lay out smoke hole depth and locations in relation to the tenon/mortise joint within the shank. I get, and understand, I think, this step in the design process....but I am very confused when it comes to the actual drilling of draft/smoke holes in sharply bent pipes, or pipes having curved shanks like, for example a Danish-style free-hand. Accuracy when drilling is needed here, or, the pipe goes into the trash bin. Expensive mistakes and plenty of cuss words are the result.

It seems, (under ideal conditions), reasonable to assume that drills can cut only a straight hole, and to a predictable depth. Drills can't be made to generate a curved hole that can follow the center-line and match the curve of a pipe's shank. A steel drill isn't flexible. When making a pipe, the path of the drilled draft-hole will come dangerously close to a shank's top-walls when drilled to intersect with the bottom of a smoke-hole. Envision the tobacco/draft holes in a full-bent pipe.

I understand -from watching at all the badly made, You-tube videos- HOW smoke-holes are drilled but I cannot find one video that explains how to design, predict, and plot the path of the drilled holes that are needed to make a bent pipe having a correctly centered draft hole that intersects perfectly with the bottom of a tobacco chamber.

Does anyone even understand what I'm trying to ask? I'm so confused! I'm not even sure how to ask my questions, it's so complicated. Trust me....I know my way around a wood and metal shop. I've been drilling holes in wood/metal for over 55 years....and yet, I still cannot generate a drilled hole that will follow a curved path as it moves down the center-line of a curved section of wood or metal....like on the shank of a bent/curved pipe. Curved, one-piece shanks, especially, have to be a PITA to drill correctly.

Get my head straightened out, please. Are there methods for drilling curved holes? Flexible drills? Drilling techniques for generating curving holes? I need some schooling.

Frank