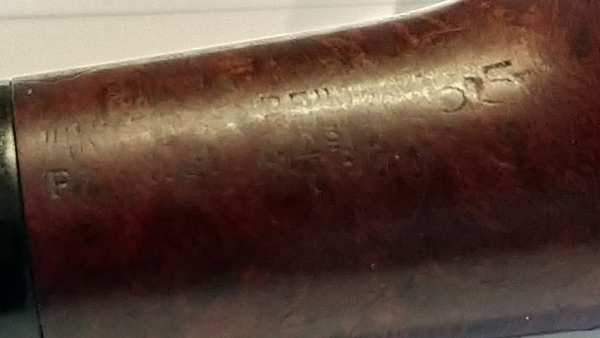

Looking to share my resurrection attempt with this "Abused 1943 Dunhill Inner Tube" pipe. I took this on to stretch my techniques. It was in such a state on the auction as to be affordable for me. Most Dunhill Ebay auctions are beyond my means.

Here is what it looked like as it arrived - Stummel dirty. Bowl full of rock hard crust. Rim used light furnaces and hammer nails. Inner tube is missing in tenon

A shot of the damaged rim, excessive cake and lava, and chip missing from rear of bowl.

Here is the wee thing in process of repair - cleaned, reamed gently, light topping to even out jagged rim periphery, extensive rim rebuild with CA glue and briar dust, lots of file work and fine sanding. Note pipe has just been cleaned - not stripped, sanded or re-stained. Rim has been touched up with stain pens however to closely match bowl patina. I want 73 years of hard service to show on this old wee thing. Stem cleaned up nicely - minor tooth chatter, button was in surprisingly good shape.

The finished result. The pipe is a beaut to smoke. Its not going to win any Ms. Pipe Universe contests, but as a 73 year old warhorse, I'll treasure her.

Here is what it looked like as it arrived - Stummel dirty. Bowl full of rock hard crust. Rim used light furnaces and hammer nails. Inner tube is missing in tenon

A shot of the damaged rim, excessive cake and lava, and chip missing from rear of bowl.

Here is the wee thing in process of repair - cleaned, reamed gently, light topping to even out jagged rim periphery, extensive rim rebuild with CA glue and briar dust, lots of file work and fine sanding. Note pipe has just been cleaned - not stripped, sanded or re-stained. Rim has been touched up with stain pens however to closely match bowl patina. I want 73 years of hard service to show on this old wee thing. Stem cleaned up nicely - minor tooth chatter, button was in surprisingly good shape.

The finished result. The pipe is a beaut to smoke. Its not going to win any Ms. Pipe Universe contests, but as a 73 year old warhorse, I'll treasure her.