I haven't posted any shop work in a while because it's usually a case of "same thing, different day". Seen one, you've seen 'em all.

This one was rather the opposite. At first glance it looks simple enough, but it was anything but. One of the five or so toughest projects I've come across.

Here's the technical story:

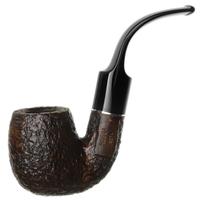

There are several stummel shape details that make creating a replacement stem for it (in this case a second, switchable stem) especially difficult.

One is when the shank is square or square-ish; another is when there are small radii involved; another is a mortise that is not centered; and still another is when the shank is neither parallel-sided nor tapered, but flared.

On the stem side of the equation the categorical killers are length---the longer a stem is, the harder it is to keep things straight---and if it is faceted. (Every variation of round, oval, and bladed are a walk in the park compared to cutting gemstone-like facets with straight edges. The reason is because "there is only one straight line" in geometry, and the slightest deviation from it can be seen by a 16 year old pug dog from thirty feet away.)

So, imagine my joy when someone wanted a replacement stem that required dealing with ALL those things. :lol: An extra-long faceted stem for a stummel that WASN'T STRAIGHT ANYWHERE. Compensating for the offset and dimensional inequalities to make everything LOOK straight in the end was the name of the game

Anyway, that's the background, here are the pics. The first three show the shape of the shank, the second shows how far off center things were (the stem was inserted upside down to illustrate), and the third shows the slight trumpeting of the shank (the side view isn't shown but it also flared). The next three show the sausage being made, and the last three show the final result.

-

-

-

This one was rather the opposite. At first glance it looks simple enough, but it was anything but. One of the five or so toughest projects I've come across.

Here's the technical story:

There are several stummel shape details that make creating a replacement stem for it (in this case a second, switchable stem) especially difficult.

One is when the shank is square or square-ish; another is when there are small radii involved; another is a mortise that is not centered; and still another is when the shank is neither parallel-sided nor tapered, but flared.

On the stem side of the equation the categorical killers are length---the longer a stem is, the harder it is to keep things straight---and if it is faceted. (Every variation of round, oval, and bladed are a walk in the park compared to cutting gemstone-like facets with straight edges. The reason is because "there is only one straight line" in geometry, and the slightest deviation from it can be seen by a 16 year old pug dog from thirty feet away.)

So, imagine my joy when someone wanted a replacement stem that required dealing with ALL those things. :lol: An extra-long faceted stem for a stummel that WASN'T STRAIGHT ANYWHERE. Compensating for the offset and dimensional inequalities to make everything LOOK straight in the end was the name of the game

Anyway, that's the background, here are the pics. The first three show the shape of the shank, the second shows how far off center things were (the stem was inserted upside down to illustrate), and the third shows the slight trumpeting of the shank (the side view isn't shown but it also flared). The next three show the sausage being made, and the last three show the final result.

-

-

-

.gif)