A Look at Classic Pieces by Rhode Island Pipecrafter Kurt Huhn

Tom Spithaler

I grew up in western Pennsylvania. As kids, my parents had taken us on several trips to the homes of friends of the family that lived in Kentucky. I remember much about those trips in spite of the fact that I was only about 7 or 8 years old, and thought the heat to be stifling. I remember swimming in TVA lakes where the water was so warm it felt like taking a bath.

What I remember most however, was my father stopping at several farms on the way home. He was fascinated by the long flowing fields of tobacco. It was a Sunday afternoon, and we stopped at farm after farm that day. Inevitably, someone was sitting on the porch, or resting under a shade tree in the front yard. My Dad would walk up to the gentleman of the house who would always rise to meet the man driving the car with Pennsylvania license plates coming their way (whether out of Southern grace or Yankee suspicion, to this day I do not know). They’d trade their greetings, exchange a few sentences, shake hands, and my Dad would just walk back to the car—empty handed. What was Dad doing? What did he want? Just one stalk of tobacco from the field?

Finally Dad found a couple sitting in the front yard under what I remember to be a weeping willow tree. The wife was snapping beans, the old farmer smoking his pipe. Dad called us all over, at which point Mom and we five kids started snapping beans to help the woman of the house. Dad and the farmer walked off towards the field, around a barn, and out of sight. We snapped beans, laughed, had some sweet tea and snapped a bushel or two of green beans before the two men came back, this time with Dad holding a prized possession. Two tobacco stalks.

Strange, but in my youth, Dad was not a smoker. I think it was on those trips however that I gained an (until recently) un-nurtured interest in tobacco. The other seed that was planted in my mind was the sheer pleasure, joy and relaxation that were on the faces of those old farmers as they sat on their steps, stoops and lawn chairs smoking their pipes. There was some majesty in that, wonderment that stirred in the heart of a boy.

What did I learn from that trip? Firstly, that there was something special about the tobacco industry, something uniquely American. Secondly that the Civil War was still being fought in the minds of more than a few tobacco farmers south of the Mason Dixon. Such was the bias of my youth. North vs. South. Yankee vs. Rebel. Now, we face a new bias, East coast vs. West Coast. Left Coast vs. Right Coast, Liberals, Conservatives. While this bias certainly plays a role in American politics, the news media and social norms, generally speaking, it does not seem to play a role in the style and character of pipe crafters. I however, am beginning to form one.

I have known Mr. Kurt Huhn for some time. We became acquainted when after starting a small pipe restoration business, I began to visit an on-line forum that Kurt so graciously hosts, and is frequented by some of the world’s greatest pipe makers. We struck up a friendship based on some shared hobbies both inside and outside the smoking pipe industry, and the next thing you know I was the owner of two of Kurt’s pipes. I was immediately struck by their quality, and have wanted to write a review of Kurt’s work for a while now. Time and other responsibilities have prevented me from getting to this review. Not to mention the fact that the first two pipes I acquired from Kurt have now been well used for a year and have become two of my favorites. I clearly needed something new to review, and what better reason (excuse) to get a couple of new pipes from Kurt! I penned Kurt an email, and the next thing you know, two new beauties showed up via US Postal service.

The pipes arrived well packaged in an ample box. I know it seems silly to review the packaging, but how many of us have received pipes through some sort of shipping process, only to have them arrive in small boxes that are hardly the right shape, too small, and with inadequate packing? I know I have, and some things have been damaged in shipping. Such was not the case here.

After unwrapping the pipes I found them both securely bundled in black hand-sewn socks with ‘man-like’ draw-strings. Again, the review is not about pipe socks, but still, I grow tired of the satin ribbons, and tiny braided cords that so many socks are bound with. These draw strings were made from black para-cord. In the Army we called Para-cord "550 cord". Why? Inside the ballistic nylon outer shell are five smaller braided nylon cords each capable of supporting a minimum of 50 pounds each, thereby giving you a finished length of string that can support more than 250 pounds of pressure. The ends of the cord are fused (presumably with a good quality pipe lighter) and knotted, and when pulling those socks closed, you know you have hold of a substantial cord. Kudos for the man-cord!

Both samples that were sent are textured. Each one blasted, not hand rusticated. Kurt has a discerning hand when it comes to blasting briar. In samples I have seen, his blasting technique ranges from a subtle, almost understated accent to the grain of the wood, to a form almost barbaric in its intensity. Each one however, artfully, and tastefully done. This is, in part, why I find Mr. Huhn’s work so exciting. Texturing is a pure art form that is only gained through experience and an intuitive understanding of the medium. Mr. Huhn has, in my opinion, mastered that art.

The first sample out of the sock is this beautiful Chubby Billiard. It is immediately identifiable as a billiard style pipe, but yet something is untraditional here. If the bowl is viewed independent of the shank, everything looks fine. But the bends into the shank from the bowl, and the shape and angle of the shank itself are reminiscent of a Salvador Dali painting. The angles appear untrue. But they are not meant to. The shank looks bent, but not bent in a traditional sense. Rather, it has an almost rolling ‘wave-like’ quality to it as it flows from the bowl, with some of it being an optical illusion. But it’s meant to. And I love it.

This quality of being a billiard, but not – and the features blending together and sort of rolling as they pass is the quality of the ‘chubby’ part of the name. Kurt describes it this way,

"Chubby billiards are an interesting breed of pipe. Given the nature of the wood, the mood of the maker at the time, bent vs. straight, you can end up a lot of different things calling themselves chubby billiards. This particular example is based on the very first chubby billiard I offered for sale, but is "supersized" – a term that is somehow apropos."

Trust me when I say that I mean no disrespect to the population that might be "waist-size challenged" (since I find myself in that very group). But by applying the same idea of ‘chubby’ to this billiard, you get the idea of parts sort of flowing together, traditional lines being blurred – sort of melting together and a little out of customary proportion. This pipe has slightly ’rounded features’ that have a wave-like action to them. This chubby billiard is a happy representation of an over-weight billiard. A few extra pounds on the waistline in this case look really good.

The texture on this pipe leans towards the aforementioned subtle side. It is not too deep, but has enough intensity to bring out the grain texture very nicely. This technique reminds me a great deal of the Danish genre, similar to some Hilson production models and some production Italians as well. Barring unpredictable flaws or character changes in the briar itself, the blasting on this Chubby is soft and smooth, somewhat sinuous in nature as if each ridge-lined crevice is actually a small lifelike tendon or ligament tying together the strength of this stout pipe’s briar soul. Spider-webbing their way out from the smokers left side of the heel of the bowl, around to the face, then backwards up and around the shank, the texture runs rampant over the surface of the pipe as if trying to regain control from some unknown force.

The color is stunning. Not distinctive in its raw palette, yet there is more there than initially meets the eye. Described by Kurt as a "deep mahogany" a closer inspection reveals lighter browns, deeper reds and a flush of yellow trying to hard to make its way to the surface and burnish itself against your eye. It puts me in the mind of a terra-cotta Tuscan rooftop. Beyond what I would call brilliant staining, the finish is ruggedly spectacular.

"For all pipes, shellac is employed in one fashion or another…shellac that is allowed to penetrate the grain slightly, then wiped off while it is still wet. This helps set the stain and bring out the natural beauty of the wood. For sandblasted pipes, shellac is used as a base finish prior to waxing with carnuba. Again, this sets the stain, preventing the dreaded "stain bleed" that can happen on heavily stained sandblasted or rusticated pipes."

Kurt went on to describe his techniques for staining and finishing in minute detail making certain I understood the finer points of the process and how much care really goes into it. Highlighting things like high quality shellac, not allowing it to set, using it to seal the stain and not the wood itself etc. This description went on in great length. In reading it I began to understand the criticism I get sometimes for being giving more details than may be necessary. At the same time, I also completely understood the process itself, and more importantly, how vital it was to Kurt that I knew how significant it was to him that this process is done right!

"Then, after the shellac is cured (about 5 minutes) the pipe can be buffed with compound and carnuba… every pipe gets a coat of wax. To keep the buildup of white particulate wax down I just make sure I’m focusing on details. You have to be aware of the direction of the deeper parts of the grain, and make sure you follow those along the rotational direction of the wheel…Like most things in pipe making, it’s heavily involved on attention to detail. The actual methodology is different for smooth or sandblasted, but the basics are the same."

The Chubby has a 7/8" diameter bowl with the depth at about 1.75", which is roughly equal to the diameter of the bowl itself at its widest point. The shank blends from the bowl at a hardy .95" and tapers ever so slightly to a .835" where the shank meets the stem. The overall length of the stummel is 3.25" make this Chubby while out of shape cardio-vascularly, well proportioned as a package just the same.

The stem, made from imported ebonite purchased exclusively from New-York-Hamburger, the US based entity of Gummi-Waaren Compagnie AG, from Lüneburg Germany is Mr. Huhn’s exclusive choice. This company has a 100 year old tradition of manufacturing and molding parts of ebonite.

"It’s not inexpensive, but the quality is worth it. I have tried other suppliers, and there are good ones out there, but they’re my favorite."

With the stem fully inserted into the mortise the overall length is just about 5.75". This leads us to my favorite part of the engineering of this pipe. The mortise and shank to stem fit.

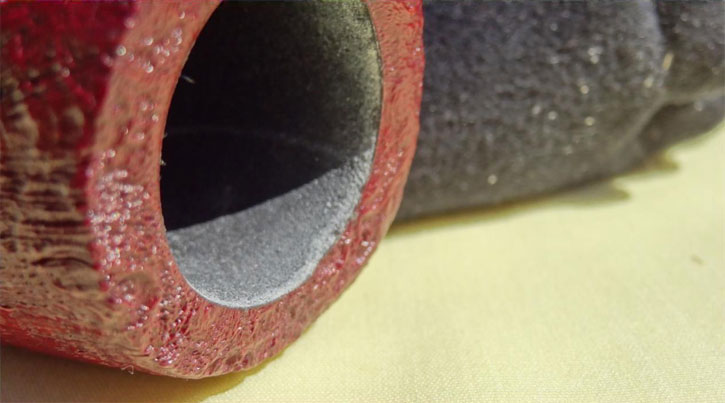

The tenon fits excellently with a secure fit that it not too tight. But on this Chubby pipe, the end of the stem actually inserts inside the end of the shank, with the shank forming a thin lip of about .045" of blasted briar that wraps around the stem receiving it like a firm and loving handshake to a depth just shy of 1/4".

Some people will look at a pipe that has a stem fitted to a smaller size than the shank and see it as a cop-out, a poor man’s fit as if to say the crafter did not have the skills to match the sizes of the diameter of the shank and the stem to fit seamlessly. Granted, this is a difficult task as any crafter will tell you, but creating a recessed fit of the stem such as Mr. Huhn did on this Chubby is no inexperienced, poor-man’s way of fitting a stem. This design requires even more skilled craftsmanship than a standard seamless fit. The mortise must be right, and the inside of the shank recess must be precise. The outside diameter of the stem must still match perfectly to the inside of that shank. When looking at the end of the shank without the stem inserted, one can see that the walls of the recessed hood are thin, but perfectly cut. This is an utterly amazing feature, and it was done to perfection.

As part of the completion of each pipe made by M. Huhn, the bowl is finished with a home recipe bowl treatment. The purpose of the bowl coating is in Kurt’s own words, to …

"…aid in cake buildup in a new pipe. The rough surface gives the ash and resins something to cling to, and speeds up the formation of cake. It can protect the pipe during break-in, a period where it is most vulnerable to the hot burning tobacco inside it."

This particular recipe is made up of a thin mixture of activated charcoal, pumice and waterglass, and is spread very thinly on the inside of the bowl.

Another reason for the bowl coating as Kurt points out, is that "it also evens out the experience of the first smokes. Every time someone buys a pipe from me, I know it will taste exactly the same – a neutral flavor that lets the tobacco shine (note, this is also a function of using good wood as well)."

Finishing his comments on this issue, he includes the purpose is, in his mind, cosmetic as well.

"I like that a coated bowl looks more "finished" than an uncoated one – though this is purely subjective."

When I asked Kurt about the nay-sayers, those that do not appreciate, support or recommend bowl coatings, he assured me that this is his personal preference, and that he realizes there are those who will not want it on their pipes. For pipes that are commissioned, or for repeat customers, Kurt will be happy to make the pipe without a bowl coating, or remove the coating from any pipe he has available for sale.

While there is little argument in the practical concept that the bowl coating aids in building cake (which in turn protects the briar itself), as Mr. Huhn stated, the aesthetic is subjective. I happen to like the appearance of a naked bowl. Something about seeing the raw briar is stimulating – there is real beauty in that wood, and some people really appreciate that. I may not share Kurt’s view on the aesthetics, but agree with his practical assessment of the value of a quality bowl coating.

Simply put, this pipe feels good in my hands. It has ‘heft’, but is fairly lightweight and does not pull on my jaw. The lines are fantastic and am a big fan of Mr. Huhn’s blasting techniques.

This Chubby Billiard is a fantastic variation on a classic theme. Bit to bowl, this custom hand-made briar pipe is masterful in its simplicity setting it above a plethora of more expensive pipes from more well known crafters. Then again, ‘well known’, much like the aesthetics of bowl coating is subjective. This will make an excellent addition to my collection, and one just like it will make an excellent addition to yours. The Chubby Billiard is a regular model available for sale on Mr. Huhn’s web site for around $225.00.

Those two Kentucky tobacco stalks hung in our Pennsylvania garage for years. Nothing ever became of them because, well, we had no idea what to do with them. They’d dry, and then get damp. We’d nibble in it a little. Smell it, sometimes in passing, but eventually they got moldy and we threw them away. I only share this part of the story because I’m confident that old man has since passed on. Good thing too – or else I know he be spittin’ mad my Dad wasted that tobacco. More than anything I am grateful to my father for exposing me to such adventures such as that as a child. Now, 40 years later, I get to sit on the back porch and share these stories with my children. Thanks to fine crafters like Kurt Huhn, I can do it with some world class pipes in my hand too – just like that old farmer in Kentucky.

Tom Spithaler is an Award Winning PSEA writer and member of the American Press Association who has cut his professional teeth in the outdoor and firearms media. Tom currently operates Born Again Briar, a small pipe sale and restoration business, blogs at www.briarmeditations.blogspot.com, and operates Spithaler Media Services, a dba of Paraklete Consulting Services, LLC. A husband of 20 years and father of three, Tom currently resides in Bonney Lake, WA. Contact: tom@bornagainbriar.com. |

Great article and review. I have visited Kurt’s site many times and slobbered over his pipes.Hope to have one someday! He not only makes great pipes but also does a great job keeping things running smoothly on the pipe makers forum. As a hobbiest pipe maker I appreciate that.

Excellent article. I thoroughly enjoyed it!

Superbly written. Very informative and brought back some memories.

Very nicely written article with great structure and imagery. Of course the essence of the review was first rate and thorough too. I’m not too sure I understand what you were trying to describe with the rolling wave transition from bowl to shank; and I’m even less clear on why your attraction to Mr. Huhn’s work constitutes a bias. But thanks for introducing him to us, and looking forward to more. Kudos on the great pix.

Great article! The story on your past is neat and the pipes are beautiful.

Great article, very informative on his techniques on making a pipe!