Steve Graves

When I first started seriously exploring corn cob pipes, my question was "Do cobs smoke as well as briars?" Now, my question has become, "Do any of my briar pipes smoke better than my cobs?"

When I first started seriously exploring corn cob pipes, my question was "Do cobs smoke as well as briars?" Now, my question has become, "Do any of my briar pipes smoke better than my cobs?"

Look, I know there are pipers who are never going to get beyond the esthetics of corn cob pipes. To some, pipe smokers should look like Fred McMurray in a cardigan – a reflective, suave, intellectual man of refined taste. Most cobbers embrace another image. We picture ourselves more like big, strapping lumberjacks — outdoorsmen, masculine, counter-cultural, rugged, individualistic, non-conformist. This is true even if we weigh 98 pounds when stepping out of the shower.

I originally ordered a few cobs to try out some Lakelands and aromatics, so as not to ghost my briars. At most, I expected to smoke a cob every now and then as a novelty or perhaps for a change of pace. I viewed cobs as being disposable; something I could give to a visitor who was interested in giving tobacco pipes a try.

When I was ready to pull the trigger on my cob order, I called the Missouri Meerschaum factory, established in 1917 in Washington, MO, and spoke with Marilyn. Marilyn is the de facto voice of the company and something of a legend in her own right, at least in the world of cob pipes. Phil Morgan, the general manager, just runs the place. Having been disappointed with the small bowl on a recently acquired Falcon, I emphasized to Marilyn that I was interested in larger sizes. Together, we settled on a Mark Twain, a Diplomat and a Freehand. I remember the bill as around fifty dollars.

Considering the factory manufactures about 3500 pipes a day, my order was handled expeditiously, arriving in around five business days. I was able to swiftly affirm that cobs didn’t need a break-in. I stuffed the monster Freehand to the top with Samuel Gawith Navy Flake, fired it off, and got a sweet, satisfying smoke from the first bowl.

Diplomat Corn Cob Pipe from Missouri Meerschaum

In quick order, I tried the other pipes over a week or so, and found nothing about which to quibble. In fact, I found that my new cobs smoked cooler, stayed lit longer, drew better, clinched easier, and were lighter than my comparable sized briars. More importantly, they opened the flavor of the tobacco. While the briars seemed to subdue tobacco flavors, the flavors from my cobs figuratively explode from the cob, like a bouquet of fireworks.

Over the next couple of weeks, I was very surprised to find myself smoking the cobs almost exclusively. Functionally, my cobs were smoking every bit as good as my mid-priced briar pipes, e.g. my Savinellis or Stanwells. I soon added a couple more Freehands, a Patriot and a General to the cob collection, among others. You can get Missouri Meerschaums stained, in clear varnish or for the lightest, coolest handling, plain naked.

Cobs may or may not smoke as well as some artisan briars but I wouldn’t know. I’ve never had the discretionary funds to buy one. But, as it turns out, I could afford several, hand-made, artisan cobs. More on this later.

If you believe the studies, I commute in the worst rush hour traffic in the country, driving from Maryland, across the District of Columbia, to Tyson’s Corner, Virginia, in the mornings and back again around 4:00 pm. The General and the Freehand soon became boon traveling companions, along with a traveler’s mug of black tea or coffee. I pack the Freehand or the General in the evening, let it rest overnight, light up as I walk out the door and set it down in my car’s pipe caddy when I arrive at the office. I relight the pipe for my afternoon commute and – most of the time — unless the traffic is especially gruesome – the bowls will burn for the entire trip home, without having to reload. That is at least two hours smoke time per bowl.

Don’t get me wrong, I still enjoy and occasionally smoke my briars and real meerschaums. As a matter of fact, last weekend I packed one of my beloved Savinelli shorts with G.L. Pease Quiet Nights, a blend I’ve been favoring quite regularly of late. But this full flavored Virginia, Turkish, Perique and Cypress Latakia blend tasted downright subdued in the briar when compared against the smoke from the cobs I have started to use habitually.

It may surprise some just how durable cobs can be. More than one cob snob has bragged that they have pipes that smoke well after ten or even fifteen years. And cobs can withstand drops and abuse perhaps better than briar. True, cobs with shellac finishes will chip if dropped on a brick walkway but in most cases, that just adds character to the naturally rustic appearance.

Last summer, I was wading while fly fishing on the Conewago Creek near Gettysburg, PA and a trout took my Adams dry fly. While setting the hook, I dropped the Missouri Meerschaum Patriot that was hanging from my mouth into the stream. After catching and releasing what turned out to be a nice brookie, I put my arm in the water and fished around until I found my cob. The dottle was soaked but hadn’t washed away. I cleaned it out and put the cob on the dashboard of my car, where it sat until the next day to dry. Because cobs are so absorbent, I didn’t have much hope for its recovery. But the next morning, I loaded her up, lit it, and to my wonder, it smoked as good as the day I bought it.

About six months after my cob conversion, I discovered that there was a thriving aftermarket for the venerable Missouri Meerschaum. It was possible to purchase custom stems and there were even carvers creating artisan pipes from stock Missouri Meerschaum cobs.

For example, Dave Wolf of Walker Briar Works (www.walkerbriarworks.com) cuts beautiful custom Lucite or Vulcanite stems to order. Called Forever Stems, they fit Missouri Meerschaum ‘Filtered’ Corn Cob Pipes and the Freehands. You’ve suffered from PAD (Pipe Acquisition Disorder), you caught a bad case of TAD (Tobacco Acquisition Disorder), now, we are SAD (Stem Acquisition Disorder). I bought four of his stems at last count. The only drawback to the Lucite stems is that they weigh more than the cheap but serviceable plastic stems provided with the original pipes. Oh, and they cost more than the cob pipes do, with the exception of the Freehand.

Dave has a thriving estate pipe business and I was surprised when he volunteered that, in his estimation, the Missouri Meerschaums Freehand smokes as good as any of his briar pipes — some of which cost hundreds of dollars. "The Freehands offer the best smoke there is. They’re really the best and the experience is very consistent. It’s absolutely unbelievable. You can light her up in the morning, smoke it all day long and it will smoke just as good at 8 o’clock at night as it did in the morning," says Dave.

Dave is a strong believer in open bores, saying that any pipe can be improved by increasing the opening to at least 4 mm (5/32 of an inch). He also opines that since the bores on cobs are already wide open, that filtered cobs burn like a furnace if they’re smoked sans the filter. This is why he designed his stems to work with those pipes, making the filters unnecessary. Some readers will be happy to know that Forever Stems for Missouri Meerschaum’s new Cobbit line are coming soon.

Wizard Cobbit from Missouri Meerschaum

As mentioned earlier, some pipe smokers are adverse to cobs because they don’t present the debonair and sophisticated image, of say, Bing Crosby sucking on a Favorite Savinelli. Well, Dave Wolf has just the cob for you. Check out his Stretch Limo or Tuxedo Dress designer pipes. The billiard shaped cobs are finished in black and fitted with a straight, white pearl stem and nickel/silver band. These pipes will match your most formal evening wear. You’ll be ready to hold court at your favorite supper club, assuming you can still find one that will permit you to smoke. If not, just use your elegant, long stemmed pipe to emphasize your scintillating conversational points.

Master tobacco blender, Russ Ouellette, is also a fan of cobs. In fact, he has created 4 blends designed especially to be burned in the poor mans’ meerschaums. One is a straight up aromatic, another is an American style burley blend, the third is a Latakia blend with a light bourbon casing and, finally, a Virginia Perique with Dark Fired Kentucky tobaccos.

I asked Russ how a blend for cobs would be different than a conventional blend. He said, "Corn is high in sugar, which sweetens the cob. I wanted to create a blend that was tuned for the cob. I began by creating the blends to taste the way I wanted them to taste in a briar. I then backed off the sweetness from the blends, for a better balance in the cobs. So, my blends are optimized for cobs."

Russ says that cobs are more absorbent than briar and they wick some of the tars, creating a smooth, natural honeyed smoke. He agrees with Dave Wolf, asserting that the chief reasons cobs smoke so well is because of their large, open, free drawing bores. He notes that modern briar artisans are moving towards larger openings for this very reason. Many are now going from the 3.2 mm standard bore to 4mm. In fact, a new factory made pipe featuring a 4mm airway will be released in the next couple of months. Called the Argo, it will be available through Pipes and Cigars at the end of February 2015.

Artisan briars can be had for around $200 but usually cost several hundred to several thousand dollars. But it is possible to commission a handsome, one-of-a kind. R. Santia artisan cob from Riccardo Santia for less than a hundred dollars, with the most expensive coming under three hundred – at least for now.

Riccardo, whose friends call him Ricco, is an artisan working in Windsor, Ontario, and is an experienced briar carver. It is tough coming up with a distinctive vision in the crowded briar scene and Ricco wanted to create something that was uniquely his own. He eventually decided that cob was to be his medium.

Stem is fitted and gets first coat of plaster.

His original designs are beautiful – hand-crafted and finished with a secret lacquer that makes the pipe look like a hundred year old colonial era collectible. R. Santias are fitted with vulcanite or acrylic stems and the bottoms of the cobs feature tapered briar plugs, to prevent burn-out. Most shanks are of bamboo.

It took a lot of time and experimentation and some spectacular failures before Ricco settled on the materials, ingredients and processes that he now uses to produce his works of art.

The pipe has received the second coat of dark walnut stain just before the lacquer. It will dry for a day.

It took Ricco months just to settle on the stains and lacquers for his new creations. Off-the shelf plasters were too brittle, so Ricco started experimenting with his own formulas. Like many inventers, most of his early attempts were failures. (Of course, if an inventor’s early attempts were successful, it would make no sense to continue with later attempts.) After 3 months of experimentation and frustration, Ricco screwed up and accidentally added an extra step to his process. By sheer serendipity, he had stumbled onto the solution that provided a heat resistant plaster with the improved flexibility and durability he was looking for. Ricco refers to the formula as his "secret sauce". He did tell me that one of the, until now, secret ingredients is wood fiber, which not only improves adhesion and sanding qualities but also strengthens the finish, adding some chip resistance. He also assures me that no toxic substances are used in his stains or plasters.

Thinking he had finally solved all the production issues, and knowing that his creations looked awesome, Ricco began selling his pipes through established dealers like Dave Neeb. But major problems soon surfaced with his first shipments.

Ricco originally used locally grown cobs to produce his first pipes. It didn’t work out. The thin walled cobs didn’t last. Not only did they have a tendency to burn out quickly, the burning cobs smoked and smelled. If that wasn’t bad enough, a few of the pipes sold actually burst into flames!

Fortunately, no one was hurt, with the exception of Ricco’s ego. Undeterred, our hero approached Missouri Meerschaum, and they cut a deal. Ricco now buys select American cobs from the factory, with the chamber pre-drilled. He has since produced over seven-hundred R. Santia pipes, all of which have proved durable – and fireproof.

Each R. Santia pipe begins with a cob blank. Ricco uses a briar dowel, which he drills out, to create a sleeve. He then drills the shank hole in the cob wall, to fit the sleeve. The sleeve extends into both the chamber and the shank, usually made from bamboo. The sturdy connecting structure eliminates shank wiggles in the wall.

This Freehand was my second Santia Pipe.

Then Ricco applies the first coat, either a stain or plaster, to the bowl. If the goal is to display the grain pattern (in this case, the grain pattern is formed by the kernel pits), the pipe might get just one coat of stain. Rusticated finishes might require 3 coats, taking at least a day to dry each coat. Virgin yellow or walnut stains may be applied at any step. Smooth finishes require sanding between each coat.

The pipe finish is an involved process that requires repeated staining and drying. Finally, Ricco sprays the pipe with his secret lacquer and it is left to dry for another day. It takes several days to a week for Riccardo to craft an R. Santia pipe, about the same as it does for some artisan briar pipes.

I first read of Ricco’s creations in the Pipes Magazine forums. After visiting his web page, I fell in love with his designs and I contracted a bad case of PAD fever. I called Ricco, chatted for a bit, and called him back the next day and commissioned him to make me a custom poker with a long bamboo stem and a curved mouth piece.

The charge came in at one hundred dollars, including shipping. Ricco is a trusting soul. He didn’t require a deposit. He billed me only after the pipe was finished. His pieces are so reasonably priced, that he would have no difficulty selling the finished pipe if a customer got cold feet and refused delivery.

We settled on the specs on a Friday evening and I received the pipe late the following week. The pipe smoked super – cool, dry and no gurgles. It was spectacularly light considering the length of the shaft and felt very comfortable in hand. There was a very faint, odd smell from the lacquer or plaster but it faded away completely within a few days. I was so pleased that I ordered three more pipes from his inventory: a straight poker with a fat bamboo shank and a couple of clenchers.

Ricco bragged that he has never been late finishing a commission, but he hastened to point out that mail service from Canada can delay delivery for American customers. Shipping to the U.S. typically takes 7 to ten days. A commission shipped to Mexico took 2 months to get to the customer. And you can’t get tracking for mail to Mexico unless you’re willing to pay fifty dollars.

I ordered this Clencher along with my Freehand from Santia.

As it turned out, my pipe was the last commission Ricco accepted for the 2014 season. His studio is an unheated shed and Ontario winters are too cold to work outside. It isn’t unusual for temperatures to drop down to twenty or thirty degrees below zero.

If you’re interested in an R. Santia pipe, you can still buy one from inventory off his web site at http://www.rsantiapipes.com/. You can also call or email Riccardo to commission a pipe for Spring delivery.

With over a dozen briars and a dozen cobs, I have fully recovered from my PAD syndromes . . . Well, maybe I’ll add just one more to the collection. Marilyn at Missouri Meerschaum told me that for an extra fifthteen dollars, they’ll make you a Freehand with the honey-like finish used on the Mark Twain. And, of course, the Argo coming from Pipes and Cigars sounds interesting . . . and Dave’s Tuxedo. . . .

My Collection Grows Quickly

An email Interview with Riccardo Santia, November 18th

I asked Riccardo to answer a few questions by email and phone. His written response follows, with some edits for clarity and brevity.

Well Steve I’m a registered massage therapist and acupuncturist. I’m also a boxer, boxing coach and a musician. I keep pretty busy.

[I ] Started crafting pipes in 1999. I started out making briar pipes but only for myself and some close friends. Right around the start of 2011. I decided to try working with cobs as a media. I picked up as many magazines on the subject of pipe making [and] using cobs that I could lay my hands on! However, there was very little on that subject matter. I perused and read countless articles, talked to other custom pipe makers but mostly just dug in and really taught myself through trial and error. I did go see Tim West, who as you know is another well-known pipe maker and all around great guy. He helped me out a few times with the making of briar pipes, which was a great help in honing my craft.

But when it came to cobs, nobody had any information on various finishes, different construction methods and so I worked on it for months. Ironically – most of my finishes failed! So after roughly 6 months of experimenting, trial and error and a lot of sweat – I had what I believe to be a prime method for applying a finish to cobs.

I used the finish on my local ‘field corn’ cobs, it lasted longer than the cob itself! The local ‘field corn’ cobs were just not strong enough to withstand the rigors of a regular smoker.

At some point, thereafter, I contacted Marilyn at MM. Marilyn was a great support, and really helped with setting my path on utilizing the correct cobs. In short – she was amazing. I started getting the MM cobs unfinished. My thought was that I could use the best of cobs and add my custom finishes to them. This proved to be the magic that customers really bought into.

Scott at Aristocob.com, and Dave Neeb were also very instrumental in my development as a pipe maker and influential when it came to knowing the market as a whole. These two men were supportive right from the start. I began selling through them and at times could barely keep up with the demand these two gentlemen were able to generate on my behalf.

Because everyone wanted my finished cobs, I began slowly developing my web presence and grew it from there. My website, rsantiapipes.com, has been up now for over 2 years and its working pretty good for me now. I am reaching the ‘700 cobs sold’ mark and average about 130 – 150 cobs on any given year.

Many ask about my methods and the steps on building my pipes – its a secret, especially my finishing techniques. What I will tell everyone is that the cobs need to be dried out, cleaned and then drilled on the bottoms including the shank hole on the cob.

My Briar heel/bottoms are finished in a taper shape so that the it will never slide out when its heated. I also fit the shank to the bowl or place a Briar dowel between a bamboo shank and the bowl inside the bamboo so that it’s not visible. Shanks are then glued to the Briar heel at the same time. From here I add the finish, which consists of about 3 layers in order to get the look of each pipe. My finishes are a combination of my learning, custom ingredients and some ‘other processes that I do not want to disclose. Even when one of my pipes are dropped it will withstand without breaking. It usually takes about 3 to 4 days for the finish to dry. The stems usually take me about 1 or 2 hours depending on complexity. Bamboo is drilled out to fit the tenon and a combination finish is used to complete that assembly. This whole process usually takes me about 5 – 7 hours depending on the complexity of the pipe.

All of my pipes are custom built pipes. I certainly don’t have an assembly line! 😉

When it comes to custom pipe requests or a ‘one off’ as they say, I can pretty much do just about as much as if it were a Briar pipe. However, I am limited to the shape of the cob. Otherwise I risk ‘burning out’ the bowl.

All my pipes are stamped R.SANTIA. It’s my trademark and one that I’ve put a lot of time and energy into. I want people that buy my products to know I am truly serious about quality of product and their satisfaction.

SIDEBAR WITH PHIL MORGAN

"A new cob may impart a sweet or tending towards sweet flavor to the tobacco. I believe cobs, after they are smoked a few times, are inert or neutral. No additional flavors are added to the tobacco from the cob. I get the truest tobacco flavor in a corn cob pipe."

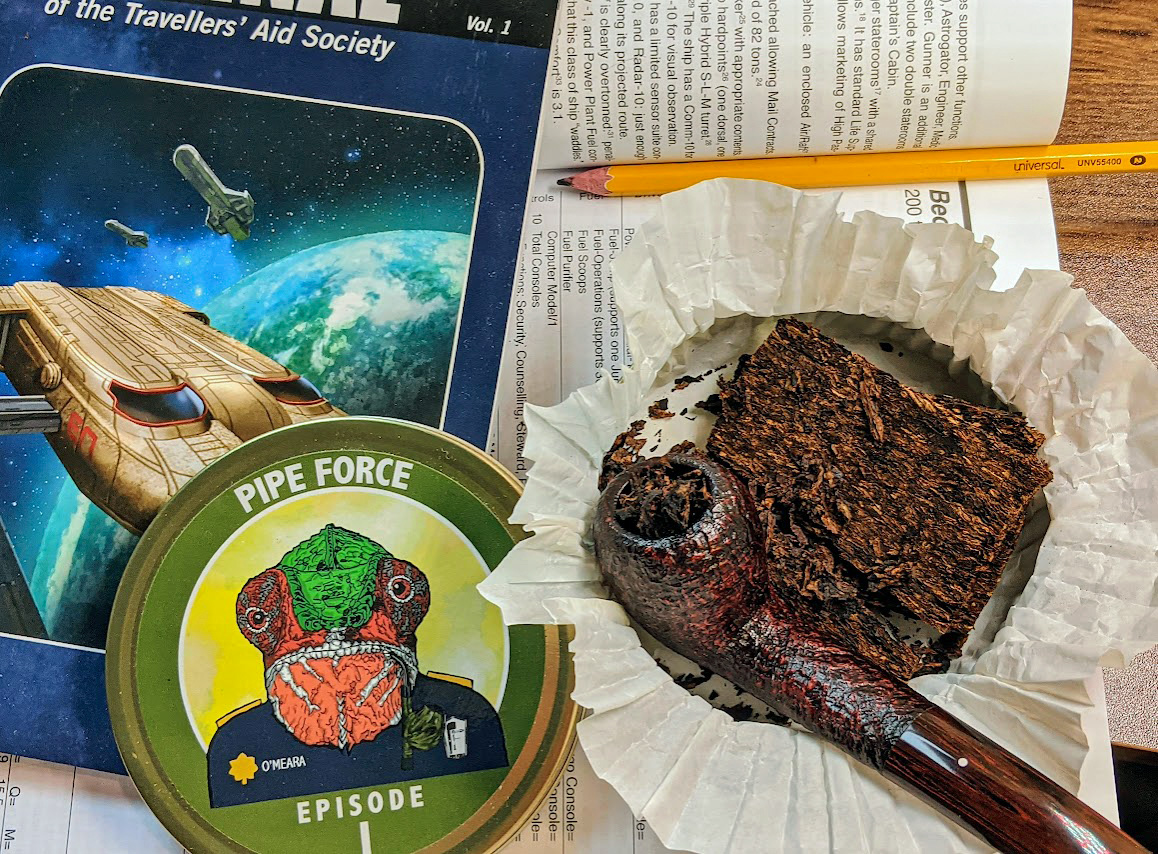

The author enjoying bowl of Balkan Sasieni in a new Sanitia custom cob.

Very nicely done! Secret sauce!

I like the way cobs smoke, but they sure don’t beat a good briar. And sadly, I must say those Santia efforts to improve on a simple cob are really hideous.

Fantastic article! :clap:

I’ve been extolling the virtues of Cobs for many years and always enjoy seeing

someone else converted to “The Cob Side”.

Great stuff Steve! 🙂

Good article!

Great article!

At first I was a little hesitant to bring out my cob around my fellow smoking friends. I expected jokes about old farts and was surprised when all of them were curious and then started to show up with them. Now when we get together it’s rare to see a briar.

I think is worth to add, that Riccardo also, has develop recently a line of cobs for the Kirsten Pipe, either straight, semibents, fullbents.

I own several of them and their attractive to the sight as they are wonderful smokers to the palate.

Very good read

If I take care of my briars, they will last a lifetime; but even with care some of the tops of the bowls on my cobs have shifted away from being symmetrically vertical, and some of the chambers on both my Diplomats and Patriots are no longer concentric. For me these signs of wear lend charm to these pipes. I in fact prefer this, rather like a ratty sweater that a wife might throw away; they certainly don’t detract from their smoking performance.

But it’s a fact that cobs aren’t as hardy as briars, and given this, dressing cobs up with finer stems, Forever stems, etc., doesn’t make sense to me. Why put money into that which has a precarious existence?

4NoggingsMike said:

But it’s a fact that cobs aren’t as hardy as briars, and given this, dressing cobs up with finer stems, Forever stems, etc., doesn’t make sense to me. Why put money into that which has a precarious existence?

Many cob smokers older than I report that they still have cobs that they smoke well after ten or even 15 years. More to the point, Forever Stems are intended to be swapped out as needed. The Forever stem can be used with replacement cobs in the event original cob does wear out.

Pax

I keep reading about how cob pipes are supposed to smoke cooler but I seem to have the opposite always happening. The tobacco always burns too hot and I just don’t find a cob pipe enjoyable at all. Am I doing something wrong? I have 5 or 6 cobs I would like to smoke if I could find a solution. Thanks.

Very nice write up. I love my MM cobs and those custom Santia jobs seem to be calling my name. Never thought about a “tricked out” cob before but now I think I must have one.

BMDFM, you didn’t say if you’re smoking Missourie Meerschaum or not. There are filtered versions which might smoke a little cooler but there is no special trick to smoking cobs. If they don’t work for you, then by all means, stick with block Meerschaum or briar pipes. Booker, thanks for the compliments. I don’t know a writer who doesn’t appreciate them. Tell Rico I sent you. Pax

Yes, I am smoking Missouri Meerschaum cobs. I always remove the filters if they have them. I think they are cool pipes, I just can’t seem to get them to work well for me. I don’t think I’ve tried them since commenting on this article a while back though. I should try them out again. I have never smoked a block meerschaum, though I would like to try one sometime. It’s just briar for me for the most part. I think I am feeling inspired to give my cobs a second try now that I am thinking about it.

BMDFM, if you haven’t yet, get hold of a Freehand or a General. The Freehand may be the best smoking pipe I own, including briars and Meerschaums. It is a big pipe and you get long, cool smokes. Yet it is light enough for clenching, at least for a few minutes. I frequently smoke it while flyfishing.